Solar cell encapsulation material composition and encapsulation sheet manufacturing method

A technology for solar cells and packaging materials, applied in the fields of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of not performing accurate evaluation of power generation efficiency decline, module performance degradation, and easy leakage, etc., to achieve stable packaging materials Structure and function, prevention of performance degradation, and excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

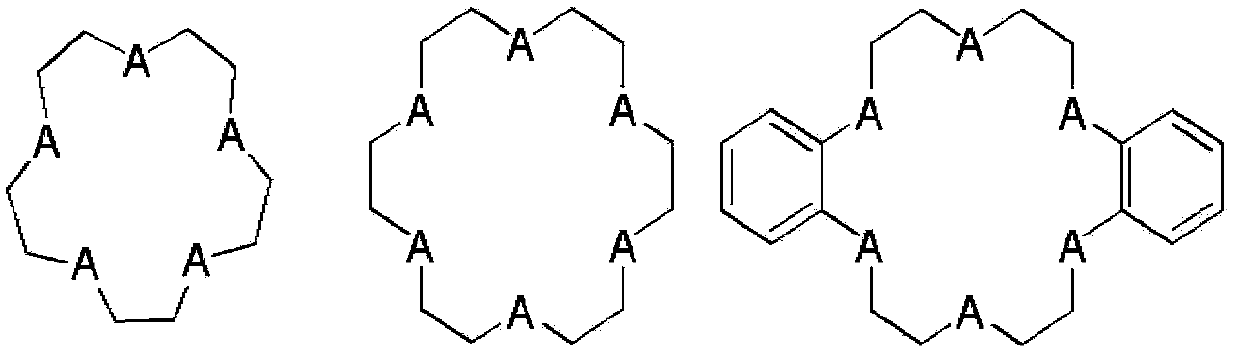

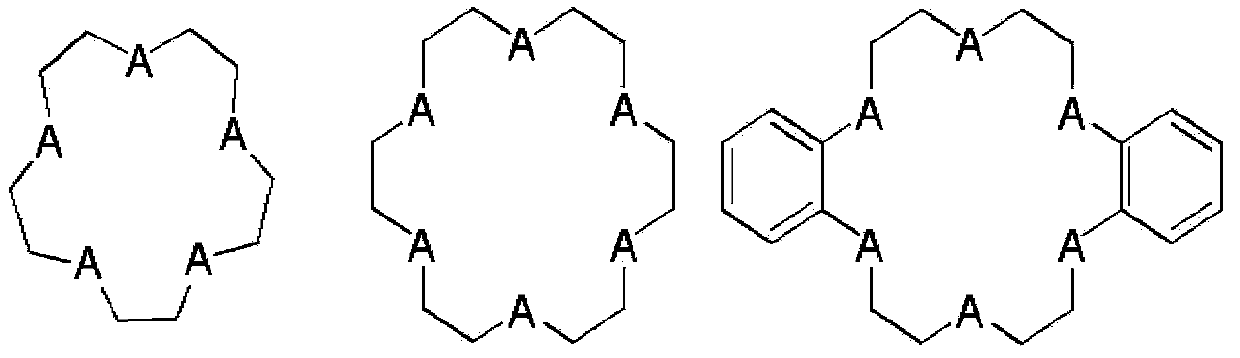

Embodiment 1

[0040] Based on 100 parts by weight of ethylene-vinyl acetate copolymer (ethylene-vinyl acetate content 28wt%, melt flow rate (MeltFlow Rate) 15g / 10min), the proportion of 2,5-dimethyl-2,5 -1.0 parts by weight of di(tert-butylperoxy)hexane (manufactured by Aldrich, Luperox101), crosslinking aid--0.8 parts by weight of triallyl isocyanurate (manufactured by Nippon Chemical Co., Ltd., TAIC), ultraviolet rays Absorbent——2-Hydroxy 4-octyloxybenzophenone (manufactured by Sumitomo Chemical Co., Ltd., sumisorb 130) 0.1 part by weight and 15-crown-5 (manufactured by Aldrich Company) 1 part by weight, 18-crown-6 (manufactured by Aldrich Company) Manufacture) 1 part by weight was rolled by a twin extruder with a diameter of 104 mm at a temperature of 110° C. or lower to manufacture a sheet with a thickness of 500 μm.

Embodiment 2

[0042] Based on 100 parts by weight of ethylene-vinyl acetate copolymer (ethylene-vinyl acetate content 28wt%, melt flow rate 15g / 10min), the proportion of 2,5-dimethyl-2,5-bis(t- Butyl peroxy) hexane (manufactured by Aldrich, Luperox101) 1.0 parts by weight, crosslinking aid---triallyl isocyanurate (manufactured by Nippon Chemical Corporation, TAIC) 0.8 parts by weight, ultraviolet absorber--- - 0.1 parts by weight of 2-hydroxyl 4-octyloxybenzophenone (Sumitomo Chemical Co., sumisorb 130) and 1 part by weight of 15-crown-5 (manufactured by Aldrich Company), passed through a double extruder with a diameter of 104mm at 110°C Rolling was carried out at the following temperature to produce a 500 µm thick sheet.

Embodiment 3

[0044] Based on 100 parts by weight of ethylene-vinyl acetate copolymer (ethylene-vinyl acetate content 28wt%, melt flow rate 15g / 10min), the proportion of 2,5-dimethyl-2,5-bis(t- Butyl peroxy) hexane (manufactured by Aldrich, Luperox101) 1.0 parts by weight, crosslinking aid---triallyl isocyanurate (manufactured by Nippon Chemical Corporation, TAIC) 0.8 parts by weight, ultraviolet absorber---2 0.1 parts by weight of -hydroxyl 4-octyloxybenzophenone (Sumitomo Chemical Co., sumisorb 130) and 1 part by weight of 18-crown-6 (manufactured by Aldrich Company) were passed through a double extruder with a diameter of 104 mm at a temperature below 110 ° C. Rolling was carried out at a high temperature to produce a 500 μm thick sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com