Preparation method for anhydrous rare earth chloride

The technology of rare earth chloride and lanthanum chloride is applied in the directions of rare earth metal chloride, rare earth metal compound, rare earth metal halide, etc., and achieves the effects of low preparation cost, simple operation and good dehydration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

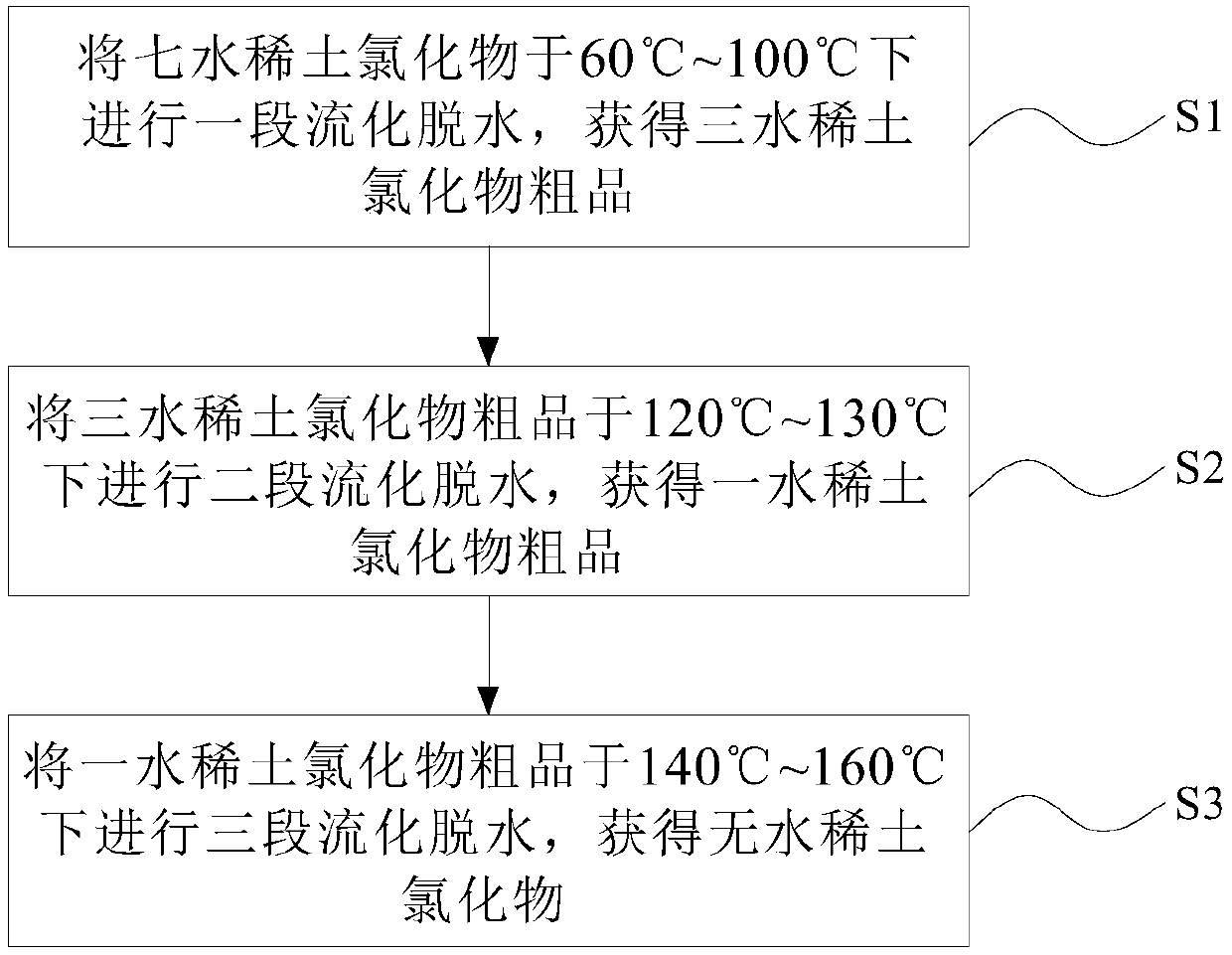

[0026] The invention provides a preparation method of anhydrous rare earth chloride. The preparation method uses rare earth chloride heptahydrate as a raw material, and specifically performs segmental fluidized dehydration under a hydrogen chloride protective atmosphere to obtain high-purity, dehydrated Good effect anhydrous rare earth chloride.

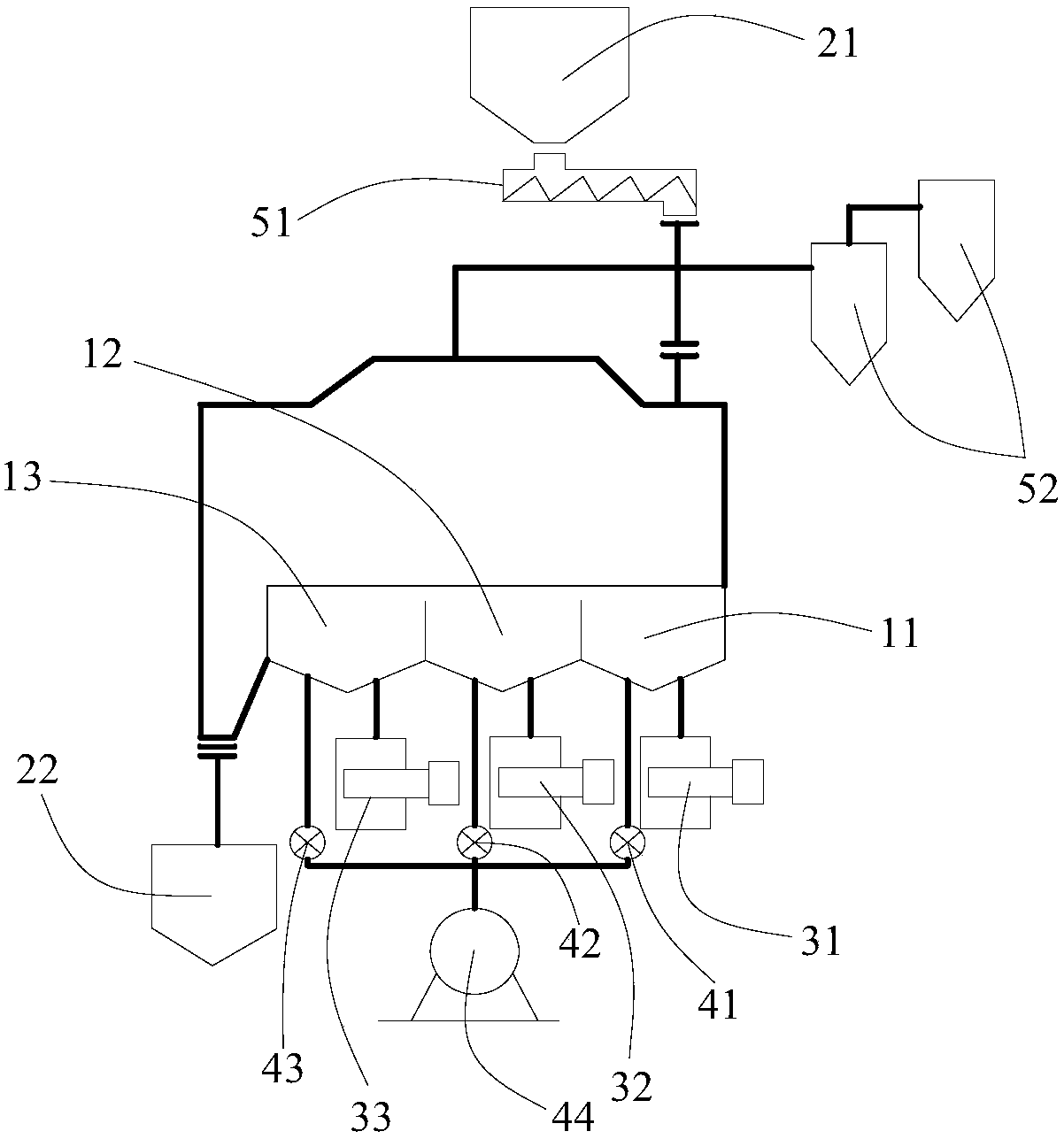

[0027] It is worth noting that the preparation method of anhydrous rare earth chlorides according to the present invention is based on a fluidized dehydration device with three chambers.

[0028] It will be understood that, although the terms "first", "second", etc. may be used herein to describe various elements, these elements should not be limited by these terms. These terms are only used to distinguish one element from another.

[0029] Specific reference figure 1 , the fluidized dehydration device includes a first fluidized chamber 11, a second fluidized chamber 12 and a third fluidized chamber 13 which are connected in sequen...

Embodiment 1

[0060] In Example 1, the dehydration raw material is a mixture of lanthanum chloride heptahydrate and praseodymium chloride heptahydrate, and the feed rate is controlled to be 100kg / h, and the temperature of one-stage fluidized dehydration, two-stage fluidized dehydration and three-stage fluidized dehydration 60°C, 120°C, and 135°C, respectively, and at the same time, the time for the first-stage fluidized dehydration, the second-stage fluidized dehydration, and the third-stage fluidized dehydration were all 20 minutes, and finally obtained anhydrous lanthanum chloride and anhydrous praseodymium chloride Mixed products.

[0061] The anhydrous rare earth chloride product obtained in this embodiment was analyzed, wherein the water-insoluble content was 5.5% (wt%); the moisture content was 7.2% (wt%) detected by the Karl Fischer moisture analyzer; XRD analysis shows that the main components of the product are anhydrous lanthanum chloride and anhydrous praseodymium chloride.

Embodiment 2

[0063] In Example 2, the dehydration raw material is a mixture of lanthanum chloride heptahydrate and neodymium chloride hexahydrate, and the feed rate is controlled to be 100kg / h, and the temperature of one-stage fluidized dehydration, two-stage fluidized dehydration and three-stage fluidized dehydration 80°C, 130°C, and 140°C, respectively, and at the same time, the time for the first-stage fluidized dehydration, the second-stage fluidized dehydration, and the third-stage fluidized dehydration were all 20 minutes, and finally obtained anhydrous lanthanum chloride and anhydrous neodymium chloride Mixed products.

[0064] The anhydrous rare earth chloride product obtained in this embodiment was analyzed, wherein the water-insoluble content was 5.0% (wt%); the moisture content was 3.6% (wt%) detected by the Karl Fischer moisture analyzer; meanwhile, the XRD analysis shows that the main components of the product are anhydrous lanthanum chloride and anhydrous neodymium chloride. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com