Fully synthetic ester-based gasoline-injection engine lubricating oil and preparation process thereof

A fully synthetic, internal combustion engine technology, applied in the field of lubricating oil, which can solve problems such as noise control, power boost emission reduction, fuel consumption reduction and mileage increase, viscosity index improver can not reduce the use amount, and the proportion of V oil can not be increased, etc. To achieve the effect of inhibiting the occurrence of side reactions, fast heating speed and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

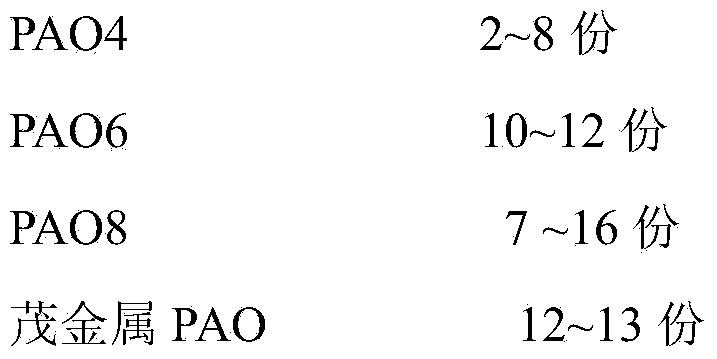

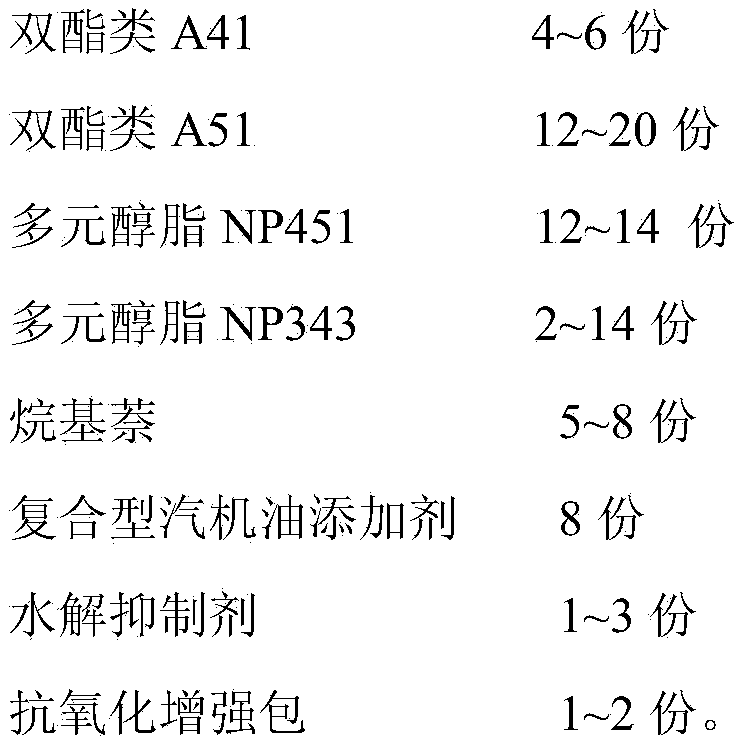

[0028] Consists of the following raw materials in parts by weight:

[0029]

[0030] The equipment used in the preparation process has a ceramic kettle with interlayer, a stirrer with ceramic blades and a rotary vane vacuum pump. The preparation process includes the following steps:

[0031] (1) Add diester A41, diester A51, polyol grease NP451 and polyol grease NP343 into a ceramic kettle with an interlayer, pump to a vacuum of 95%, and stir at 30°C for 10 minutes;

[0032] (2) Add triethanolamine and alkylnaphthalene 5, and stir for 10 minutes at 30°C;

[0033] (3) Heat the material to 70°C by passing steam into the interlayer, and stir and react for 1 hour;

[0034] (4) Add PAO4, PAO6, PAO8, and metallocene PAO150 in sequence, heat to 90°C, and stir for 30 minutes;

[0035] (5) Add Lubrizol 21102 and alkyl diphenylamine, heat to 100°C, and stir for 45 minutes;

[0036] (6) Turn off the heating steam in step (3), pass cooling water into the interlayer, and cool down to...

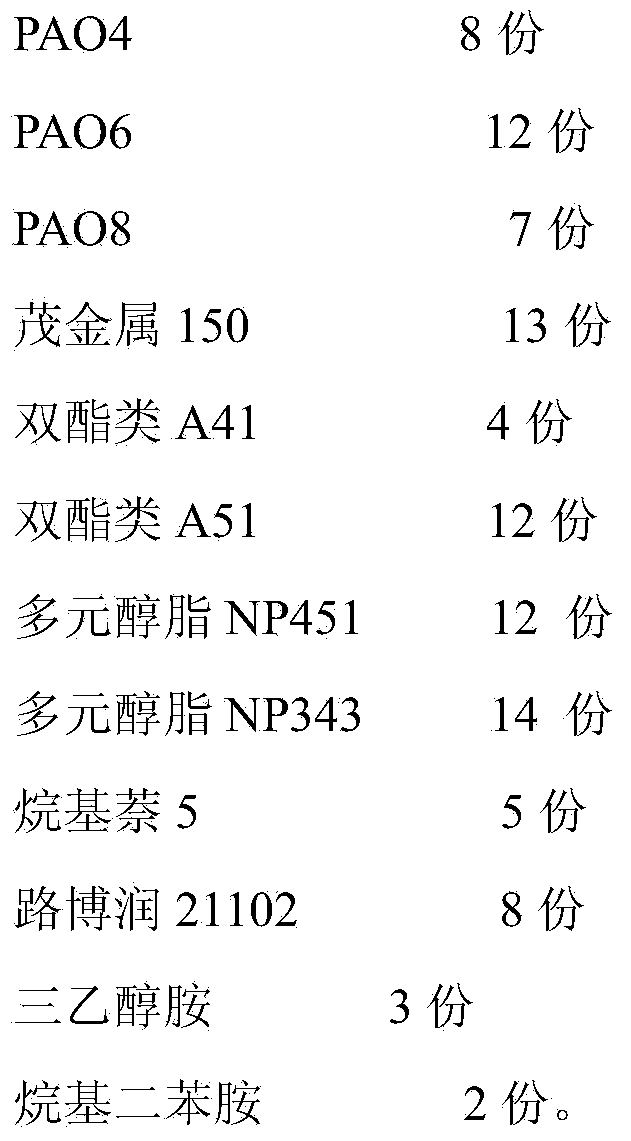

Embodiment 2

[0041]

[0042]

[0043] The equipment used in the preparation process has a ceramic kettle with interlayer, a stirrer with ceramic blades and a rotary vane vacuum pump. The preparation process includes the following steps:

[0044] (1) Add diester A41, diester A51, polyol grease NP451 and polyol grease NP343 into a ceramic kettle with an interlayer, evacuate to a vacuum of 90%, and stir at 20°C for 20 minutes;

[0045] (2) Add dimethylformamide and alkylnaphthalene 5, and stir for 10 minutes at 20°C;

[0046] (3) Heat the material to 60°C by passing steam into the interlayer, and stir and react for 2 hours;

[0047] (4) Add PAO4, PAO6, PAO8, and metallocene PAO150 in sequence, heat to 80°C, and stir for 30 minutes;

[0048] (5) Add Mobil 6040 and T561, heat to 100°C, and stir for 45 minutes;

[0049] (6) Turn off the heating steam in step (3), pass cooling water into the interlayer, and cool down to room temperature to obtain ester fully synthetic 5w40 gasoline engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com