Preparation method and application of magnesium-titanium co-doped cobalt carbonate

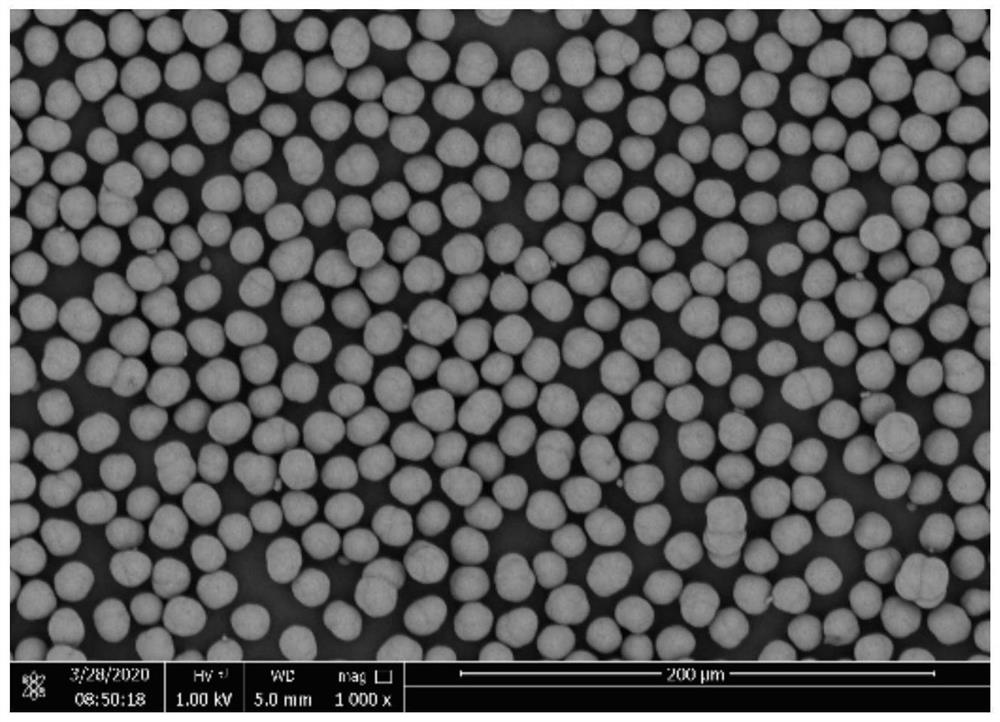

A technology of co-doping and cobalt carbonate, applied in the direction of cobalt carbonate, structural parts, electrical components, etc., to achieve the effect of concentrated particle size distribution, increase adsorption capacity, and promote growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

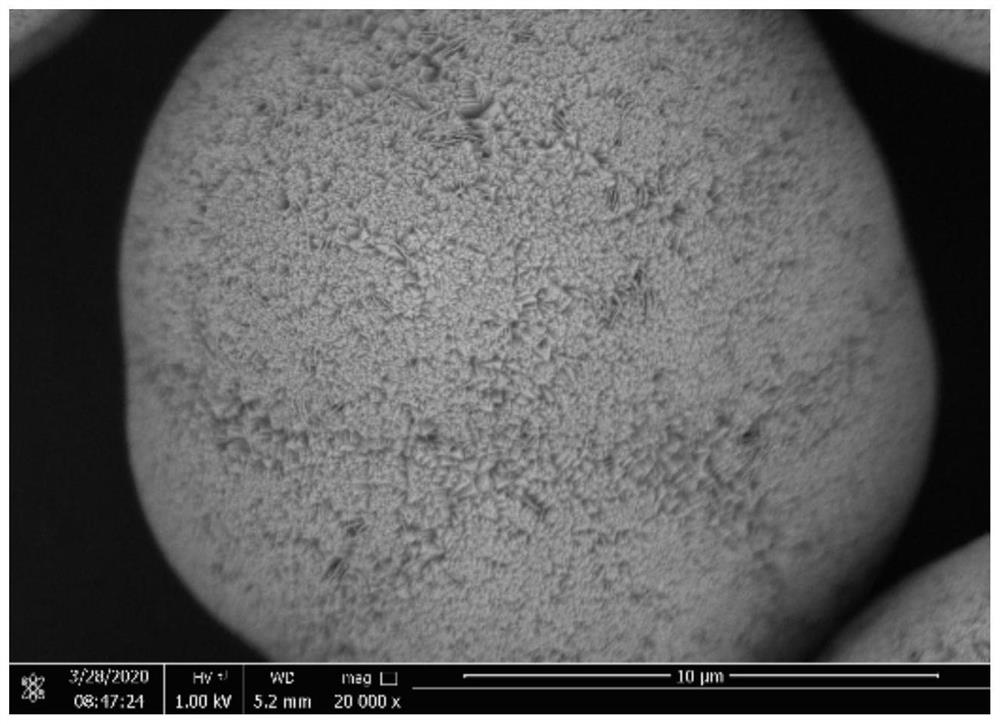

Embodiment 1

[0042] The present embodiment prepares a magnesium-titanium co-doped cobalt carbonate, and the specific process is:

[0043] Step 1. Prepare a solution: configure a cobalt-magnesium mixed metal solution A of cobalt chloride and magnesium chloride, wherein the cobalt concentration is 2.0mol / L, the mass ratio of magnesium-cobalt elements is 0.005, and a mixed solution C of citric acid and titanium chloride is configured, wherein The concentration of titanium ions is 0.05mol / L, the molar ratio of citric acid to titanium is 0.2, the pH of the mixed solution C is 0.8 at room temperature, and the mixed precipitant solution B of ammonium bicarbonate solution and ammonium dodecyl sulfate is configured, wherein The concentration of ammonium bicarbonate is 3mol / L, and the mass ratio of ammonium dodecyl sulfate and ammonium bicarbonate is 0.05;

[0044] Step 2. Synthesis of magnesium-titanium co-doped cobalt carbonate: pure water and ammonium bicarbonate solution are added to the reaction ...

Embodiment 2

[0048] The present embodiment prepares a magnesium-titanium co-doped cobalt carbonate, and the specific process is:

[0049] Step 1. Prepare a solution: configure a cobalt-magnesium mixed metal solution A of cobalt sulfate and magnesium sulfate, wherein the cobalt concentration is 1.8 mol / L, the mass ratio of magnesium-cobalt elements is 0.008, and a mixed solution C of tartaric acid and titanium sulfate is configured, wherein titanium ions are The concentration is 0.18mol / L, the molar ratio of tartaric acid to titanium is 0.6, the pH of the prepared mixed solution is 0.5 at room temperature, and the mixed precipitant solution B of ammonium bicarbonate solution and sodium laurate is configured, wherein the concentration of is 2.5mol / L, and the mass ratio of sodium laurate to ammonium bicarbonate is 0.10;

[0050] Step 2. Synthesis of magnesium-titanium co-doped cobalt carbonate: pure water and ammonium bicarbonate solution are added to the reaction kettle as the bottom liquid,...

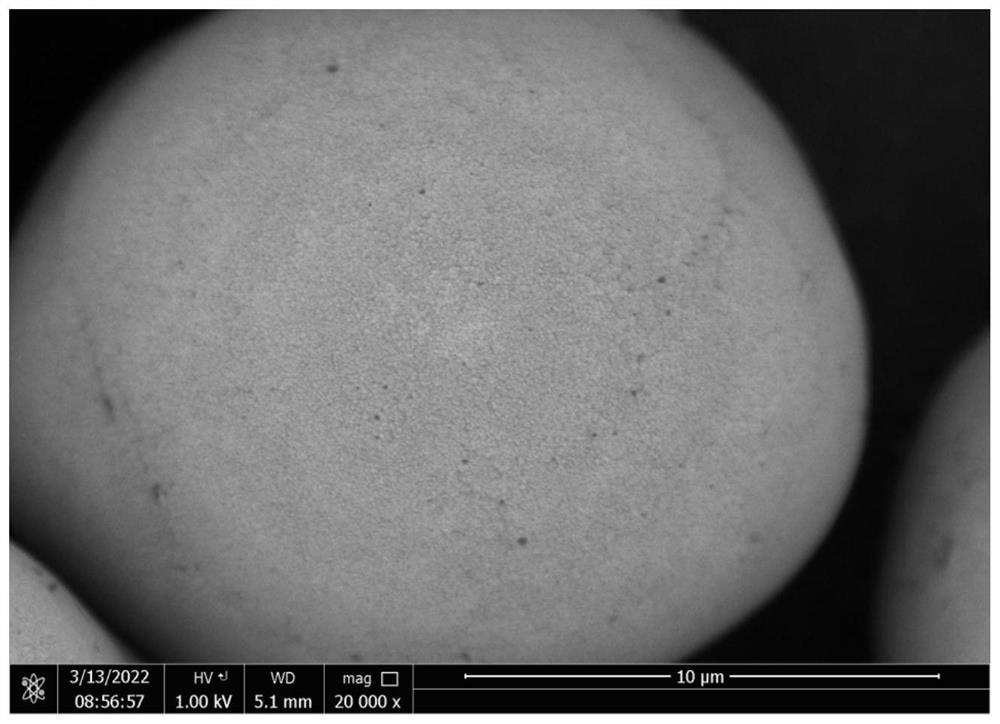

Embodiment 3

[0054] The present embodiment prepares a magnesium-titanium co-doped cobalt carbonate, and the specific process is:

[0055] Step 1. Prepare a solution: configure a cobalt-magnesium mixed metal solution A of cobalt nitrate and magnesium nitrate, wherein the cobalt concentration is 1.5mol / L, the mass ratio of magnesium-cobalt elements is 0.01, and a mixed solution C of gluconic acid and titanyl sulfate is configured, wherein The titanium ion concentration is 0.1mol / L, the molar ratio of gluconic acid and titanium is 0.5, the pH of the prepared mixed metal solution is 1.0 at room temperature, and the mixed precipitant solution B of ammonium bicarbonate solution and polyacrylamide is configured, in which carbonic acid The concentration of ammonium bicarbonate solution is 2.0mol / L, and the mass ratio of polyacrylamide to ammonium bicarbonate is 0.15;

[0056] Step 2. Synthesis of magnesium-titanium co-doped cobalt carbonate: pure water and ammonium bicarbonate solution are added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com