Hydrolyzation tolerant sulfonated polyimide proton exchange membrane and preparation thereof

A sulfonated polyimide, proton exchange membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of enhancing hydrophobicity and inhibiting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

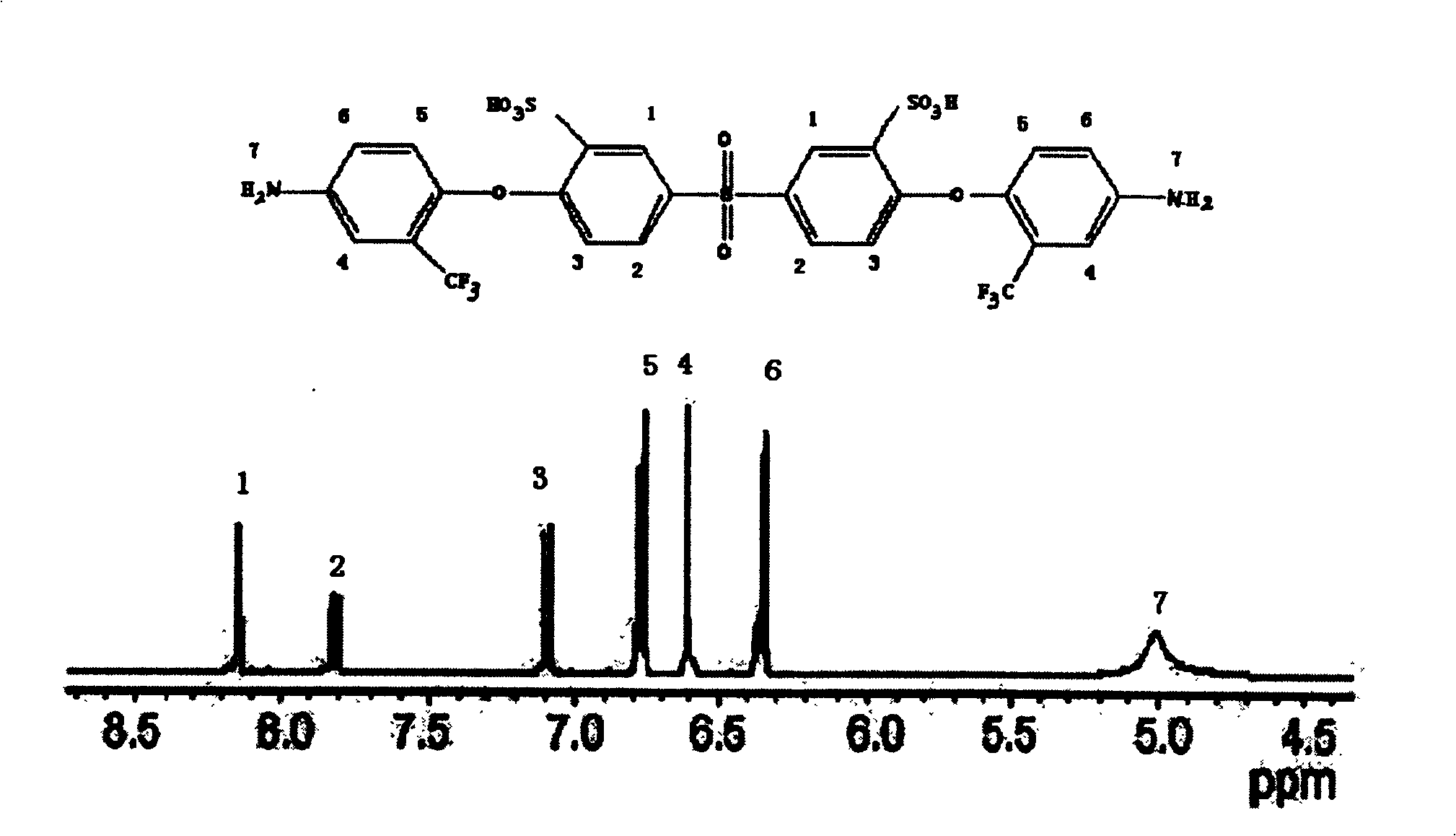

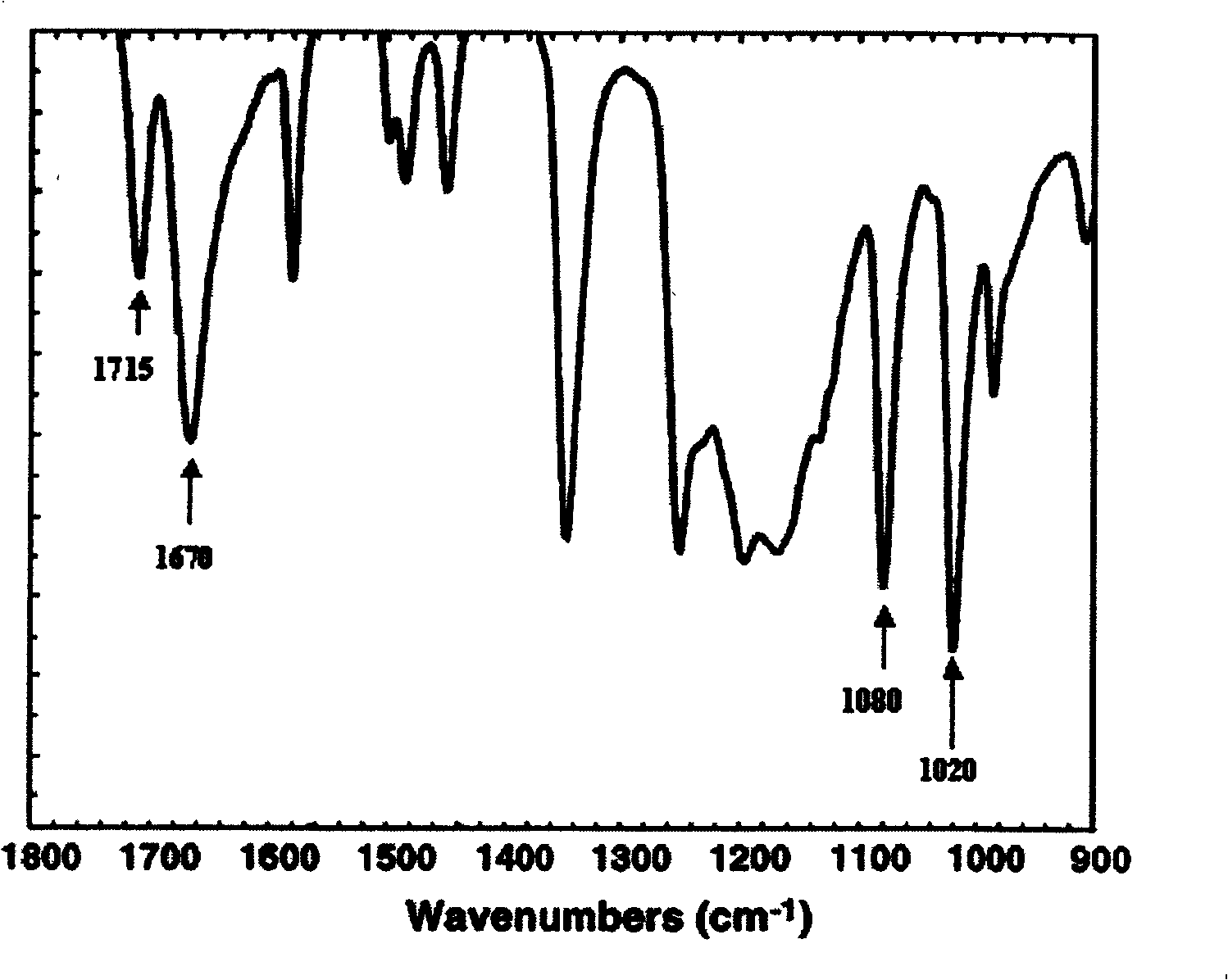

[0024] Preparation Example 1

[0025] (a) Combine 41g (0.1mol) 3,3'-disulfonic acid-4,4'-dihydroxydiphenylsulfone and 41.8g (0.2mol) 2-fluoro-5nitrophenyl trifluoromethane at room temperature Dissolved in a mixed solvent of 100g of N-methyl-2-pyrrolidone, 150g of toluene, 6g of sodium hydroxide and 10g of deionized water, in a nitrogen environment, the temperature is raised to 160°C, after 4 hours of reaction, it is then raised to 190°C for reaction 16 After the reaction is over, the reaction product is cooled to room temperature. After suction filtration with a Buchner funnel, the filtrate is poured into 200 g of anhydrous ethanol solvent while stirring rapidly to form a precipitate. After suction filtration, the filter cake is placed at 80°C Heat and stir in deionized water for 3 hours, and then filter with suction to obtain 64.6 g of nitro-terminated fluorine-containing sulfonated aromatic ring polymer with a yield of 82%;

[0026] (b) Dissolve 20g of nitro-terminated fluorine-...

Example

[0028] Preparation Example 2

[0029](a) 38.8g (0.1mol) 3,3'-disulfonic acid-4,4'-dihydroxyphenyl hexafluoropropane and 41.8g (0.2mol) 2-fluoro-5nitrophenyl trifluoromethane Dissolve in a mixed solvent of 100g N-methyl-2-pyrrolidone, 150g toluene, 6g sodium hydroxide and 10g deionized water at room temperature. In a nitrogen environment, the temperature is raised to 160°C. After 4 hours of reaction, the temperature is raised to 190 React at ℃ for 16 hours. After the reaction is complete, cool the reaction product to room temperature. After suction filtration with a Buchner funnel, pour the filtrate into 200 g of absolute ethanol solvent while stirring rapidly to form a precipitate. After suction filtration, place the filter cake Heat and stir in deionized water at 80°C for 3 hours, and then filter with suction to obtain 55.9 g of fluorine-containing sulfonated aromatic ring polymer with terminal nitro groups, with a yield of 73%;

[0030] (b) Dissolve 20g of nitro-terminated fluor...

Example

[0032] Preparation Example 3

[0033] (a) 37.4g (0.1mol) 3,3'-disulfonic acid-4,4'-dihydroxybenzophenone and 41.8g (0.2mol) 2-fluoro-5nitrophenyl trifluoromethane at room temperature Dissolve it in a mixed solvent of 100g N-methyl-2-pyrrolidone, 150g toluene, 6g sodium hydroxide and 10g deionized water. In a nitrogen environment, the temperature is raised to 160℃, and after 4 hours of reaction, the temperature is raised to 190℃ for reaction. After 16 hours, after the reaction, the reaction product was cooled to room temperature. After suction filtration with a Buchner funnel, the filtrate was poured into 200 g of anhydrous ethanol solvent while stirring quickly to form a precipitate. After suction filtration, the filter cake was placed at 80 Heat and stir in deionized water at ℃ for 3 hours, and then filter with suction to obtain 63.9 g of fluorine-containing sulfonated aromatic ring polymer with terminal nitro groups, with a yield of 85%;

[0034] (b) Dissolve 20g of nitro-termin...

PUM

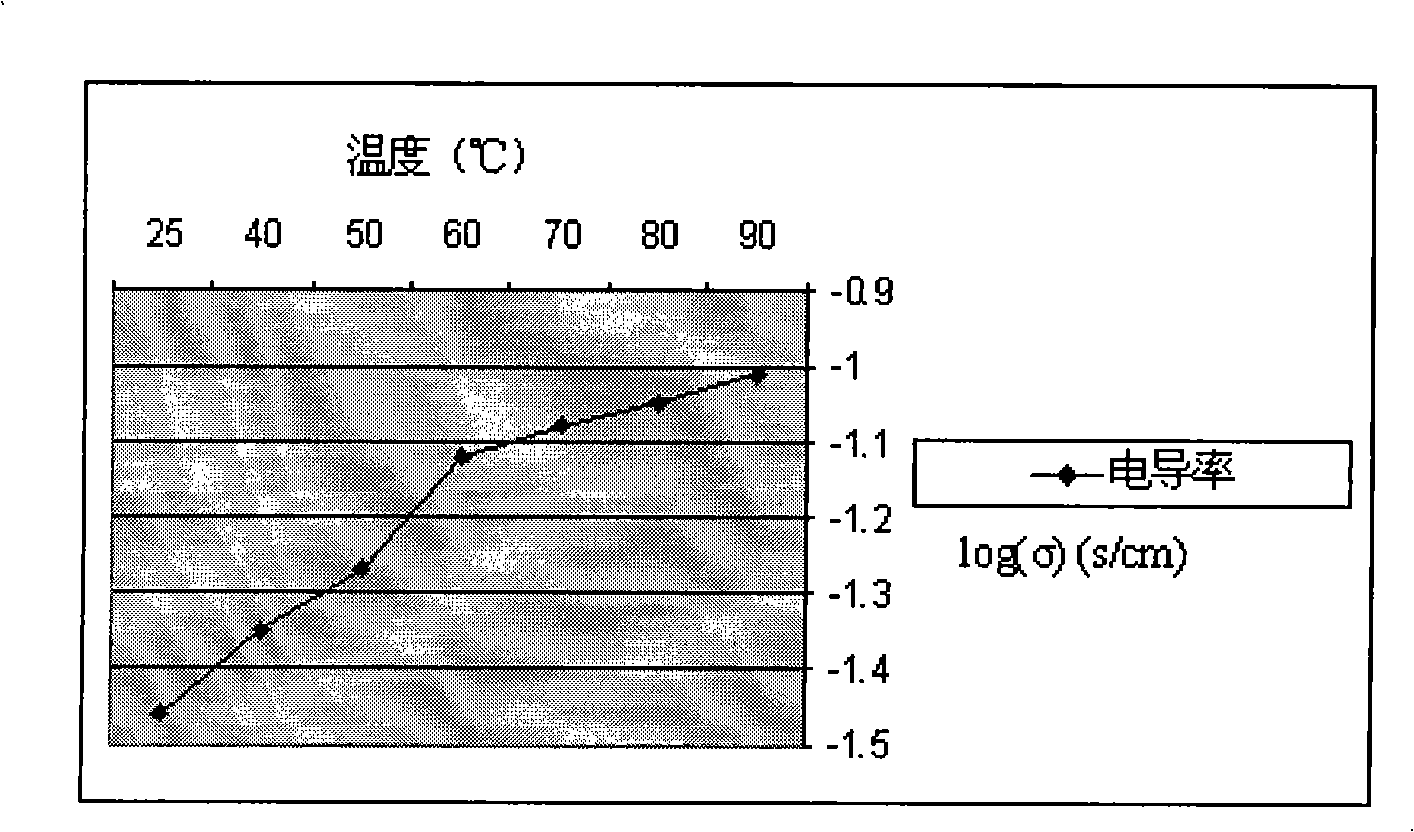

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com