Flame-retardant resin composition

A resin composition and flame retardant technology, applied in the field of flame retardants, can solve the problems of difficulty in imparting high flame retardancy, poor flame retardant effect, exudation heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The preparation method of the above-mentioned phosphate ester amides is not particularly limited, and reference can be made to JP-A No. No. 10-175985, Jomal Of Chem.Soc.C, 3614 (1971), JP-A No. 8-59888, JP-A 63-235363, JP-A 54-19919, etc. For example, in the presence of an amine catalyst or metal chloride, by (1) reacting phosphorus oxyhalide with phenols and then reacting with amines, (2) reacting phosphorus oxyhalide with amines and then reacting with phenols Method of reaction, (3) method of reacting phenyl dihalophosphate with amines, (4) method of reacting diphenyl halophosphate with amines, (5) method of reacting diphenylphosphate with amines method and so on.

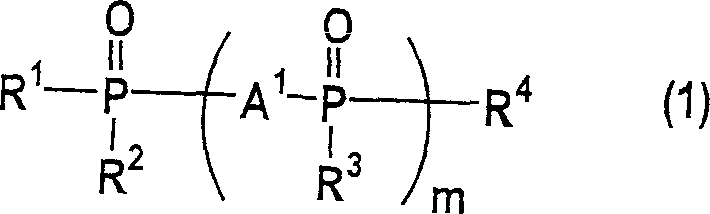

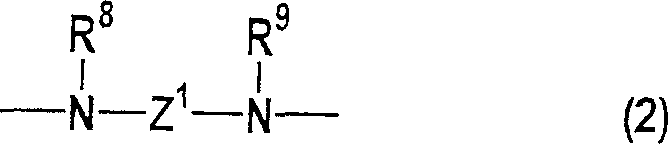

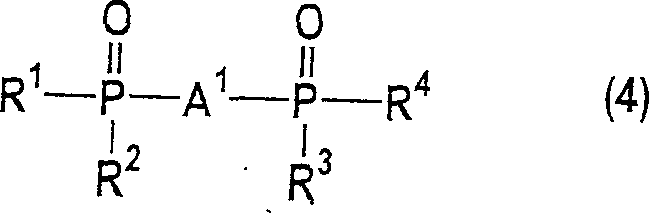

[0090] As preferred phosphoric acid ester amides, compounds described in the above-mentioned patent publications and high molecular weight polycondensed phosphoric acid ester amides can be used. As these phosphate ester amides, there are, for example, N-(diaryloxyphosphinyl) substituted alkyleneamines [e...

Embodiment 1~40

[0482] Examples 1-40 and Comparative Examples 1-11

[0483] The above components were mixed according to the proportions (parts by weight) in Table 1 to Table 5, and the resin composition was obtained by kneading and extruding with an extruder. These resin compositions were injection molded into molded articles for combustion tests and molded articles for tensile evaluation, and their flammability, blooming properties, and hydrolysis resistance were evaluated. The results are shown in Tables 1-5.

[0484] It can be clearly seen from the table that combining the flame retardant composed of phosphorus-containing compound (A), aromatic resin (B), and specific flame retardant additive (C) with specific stabilizing additive (functional compound and / or hydrophobic Compared with the comparative example lacking any one of the components, the examples used in combination with the active compound) (D) all have good flame retardancy, blooming property and hydrolysis resistance.

[0485...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com