Resin composition, method for producing resin composition, and molded article

A technology of resin composition and manufacturing method, which is applied in the field of resin composition, can solve the problems of flame retardancy, fluidity, appearance deterioration, etc., and achieve the effect of excellent appearance and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~6

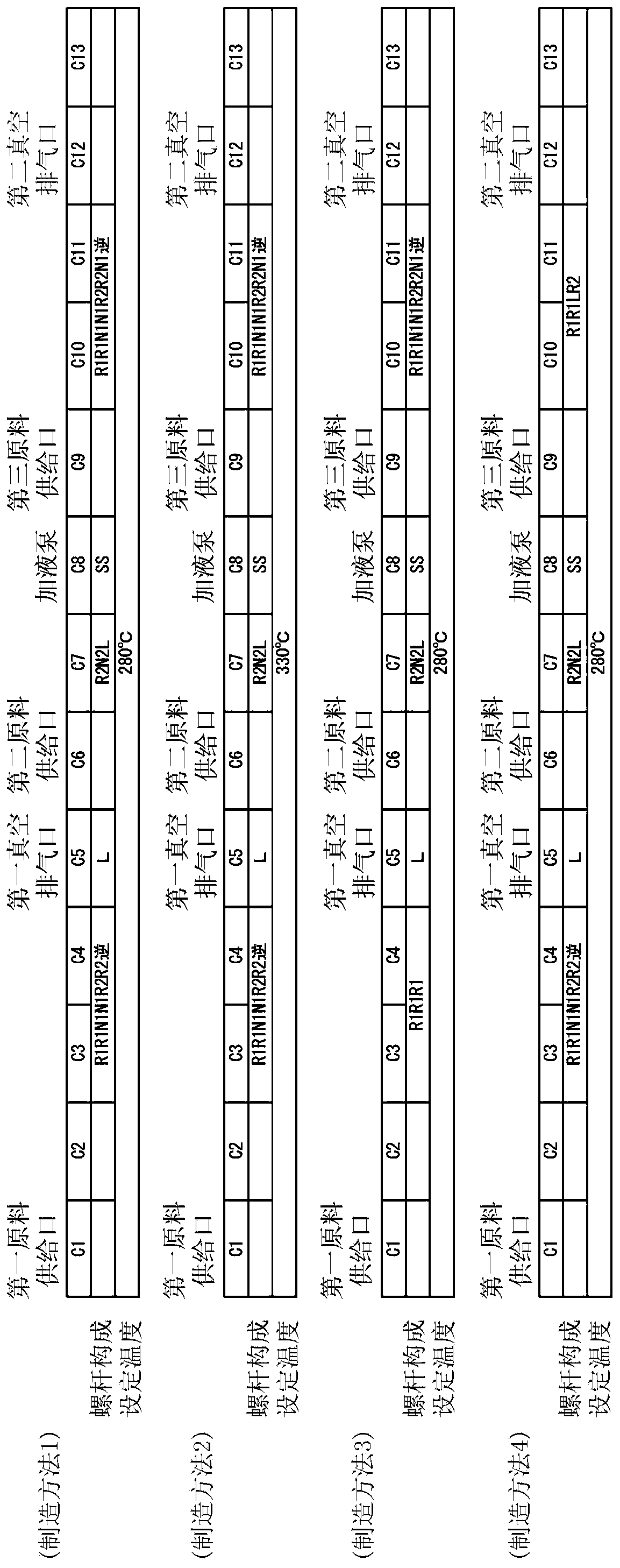

[0227] In the twin-screw extruder set as above, under the composition and production conditions shown in Tables 1 and 3, melt kneading was carried out at a discharge rate of 400 kg / hour to obtain pellets of the resin composition.

Embodiment 11

[0229] In the twin-screw extruder set as above, under the composition and production conditions shown in Table 2, melt kneading was carried out at a discharge rate of 400 kg / hour. First, the first resin composition is produced, and then the second resin composition is produced using the first resin composition to obtain pellets of the resin composition.

[0230] About each Example and a comparative example, the evaluation of the resin composition was performed by the said measuring method, and the result is shown in Tables 1-3.

[0231] 【Table 1】

[0232]

[0233] 【Table 2】

[0234]

[0235] 【table 3】

[0236]

[0237] As shown in Tables 1, 2, and 3, it can be seen that in Examples 1 to 11, the shrinkage of the test piece after aging at a temperature of 150°C and 24 hours is 6% to 20%, and the fluidity, flame retardancy , Excellent mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com