Anti-bacterial composite paint for fabrics and preparation method of anti-bacterial composite paint

A composite coating and fabric technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as irritation, multiple processes of raw materials, and complexity, and achieve the effects of increased viscosity, stable use, and excellent processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

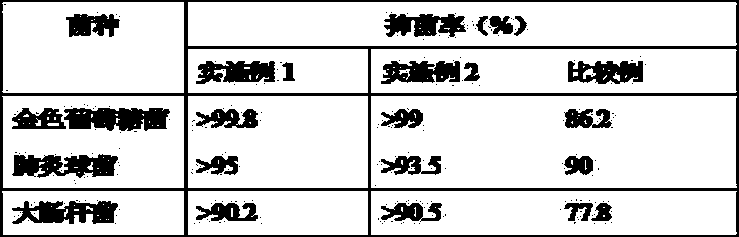

Examples

Embodiment 1

[0028] The preparation of the substrate coating comprises the following raw materials by weight: 60 parts of unsaturated polyester resin, 5 parts of silver-coated copper powder, 3 parts of 1,4-butanediol, 10 parts of triethylamine, 3 parts of nano-zinc oxide, 0.2 parts of jade powder;

[0029] Prepare the surface coating and include the following raw materials in parts by weight: 10 parts of polyvinyl alcohol, 15 parts of tea tree oil, 9 parts of zinc sulfide, 1 part of butadiene-styrene, 1.3 parts of adipate ester polyester plasticizer, 4 parts Parts of magnesium-containing alumina, 0.2 parts of fumed silica.

[0030] To carry out antibacterial composite coating treatment to polyester fabric, adopt the following steps:

[0031] After scraping the substrate paint on the fabric 3 times repeatedly, the thickness is 150um, and drying at 150°C for 5 minutes; then brush the surface paint 3 times, the thickness of the coating is 270um, put it in a cool place for 15 hours to dry, fu...

Embodiment 2

[0033] The preparation of the substrate coating includes the following raw materials in parts by weight: 65 parts of unsaturated polyester resin, 4 parts of silver-coated copper powder, 7 parts of 1,4-butanediol, 10 parts of triethylamine, 3 parts of nano-zinc oxide, 0.5 parts of jade powder, 0.3 parts of calcined kaolin modified by aluminum-titanium composite coupling agent;

[0034] Prepare the surface coating and include the following raw materials in parts by weight: 13 parts of polyvinyl alcohol, 13 parts of tea tree oil, 8 parts of zinc sulfide, 5 parts of butadiene-styrene, 1.3 parts of adipate ester polyester plasticizer, 4 parts Parts of magnesium-containing alumina, 0.4 parts of fumed silica.

[0035] To treat pure cotton fabric with antibacterial composite coating, the following steps are adopted:

[0036] After scraping and coating the substrate paint on the fabric 3 times repeatedly, the thickness is 130um, and dry it at 150°C for 4 minutes; then brush the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com