Modified fly ash, preparation method thereof, and preparation apparatus thereof

A technology of fly ash and ultra-fine fly ash, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and fibrous fillers. It can solve the problem of non-spherical particles, uneven particle surface distribution, and large dosage. To meet the coupling and filling effect, improve the economic value, and achieve the effect of large production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

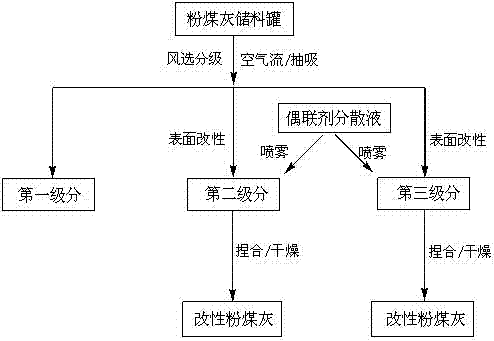

[0034] Such as figure 1 As shown, the fly ash in the fly ash storage tank is sent into the gas-material mixer with compressed air, and under the suction of the induced draft fan, the fly ash particles are introduced into the cyclone air flow separator through the pipeline along with the air flow , Air separation and grading are carried out in the negative pressure system of the closed equipment. The cyclone airflow separator includes a first-stage separator, a second-stage separator, and a third-stage separator.

[0035] Switch the air flow and control the small suction force of the fan, so that the coarse particles spiral down in the first stage sorter, and are discharged through the discharge port and stored in the container (accounting for about 15% of the weight of the original ash). The coarse particles are fractions rich in magnetic iron oxide, which can be directly used as magnetic fillers, or further obtained through magnetic separation to obtain high-grade magnet raw...

Embodiment 2

[0040] refer to figure 1 , the fly ash in the storage tank is sent into the gas-material mixer with compressed air, and under the suction of the induced draft fan, it is introduced into the cyclone air flow separator through the pipeline along with the air flow, and the suction force of the fan at this stage is adjusted. In Example 1, the corresponding wind force is slightly stronger, and the coarse particles spirally descend in the first stage sorter, and are discharged through the discharge port and stored in the container (accounting for about 30% of the weight of the original ash).

[0041] With reference to Example 1, further, by switching the swirl flow and maintaining the suction force of the fan at this stage is basically the same as the corresponding wind force in Example 1, subdividing in the second stage sorter to obtain ultrafine particles above 1200 mesh . Ultrafine particles above 1,200 mesh enter the second-stage sorter and descend spirally (accounting for abou...

Embodiment 3

[0045] The fly ash in the storage tank is sent into the gas-material mixer with compressed air, and under the suction of the induced draft fan, it is introduced into the cyclone air flow separator through the pipeline along with the air flow, and the suction force of the fan at this stage is controlled more effectively. In Example 2, the corresponding wind force is stronger, and the coarse particles spiral down in the first stage sorter, and are discharged through the discharge port and stored in the container (accounting for about 50% of the original ash weight).

[0046] With reference to Example 1, further, by switching the swirling flow and maintaining the process conditions that the suction force of the fan at this stage is basically the same as the corresponding wind force in Example 1, subdivide in the second stage separator to obtain more than 2000 mesh ultrafine particles. Ultra-fine particles above 2000 mesh enter the second-stage sorter and descend spirally (account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com