Efficient halogen-free flame retardant butadiene styrene rubber composition and preparation method thereof

A technology of styrene-butadiene rubber and its composition, which is applied in the field of styrene-butadiene rubber composition and its preparation, can solve the problems of low flame retardant efficiency of magnesium hydroxide, deterioration of the mechanical properties of the matrix, and difficulty in molding and processing, and achieve excellent mechanical properties and low price. Effects of low cost and reduced use of carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

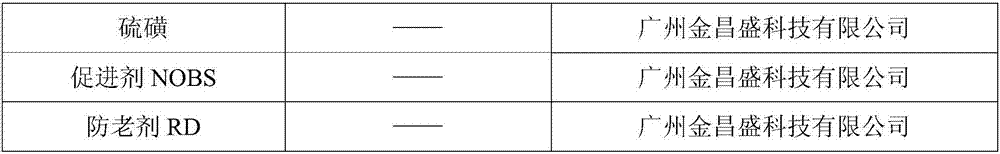

[0039] Examples 1-3 The proportioning ratio of each raw material of the high-efficiency halogen-free flame-retardant styrene-butadiene rubber composition is shown in Table 2, and the preparation method is as follows:

[0040] A. Prepare styrene-butadiene rubber, hydroxymethyl lignin, transition metal silicate, magnesium hydroxide, carbon black, activator, antioxidant, accelerator and vulcanizing agent by mass parts;

[0041] B. Disperse hydroxymethyl lignin in styrene-butadiene rubber in the form of irregular spherical particles, and use rubber processing equipment to mix the rubber mixed with hydroxymethyl lignin to obtain hydroxymethyl lignin-filled styrene-butadiene rubber rubber composition;

[0042] C. Move the rubber composition in step B to an open mill, and at room temperature, add activator, anti-aging agent, carbon black, transition metal silicate, magnesium hydroxide, vulcanizing agent and accelerator successively for mixing ; Thin bag rolls out the sheet again, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com