Nano composite fire retardant parent material, preparation method and application

A flame-retardant masterbatch and nano-composite technology, which is applied in the direction of fire-resistant coatings, etc., can solve the problems of plastic substrates with greater influence on mechanical properties, low melting point and boiling point, and easy to be volatilized by heat, so as to achieve less damage to comprehensive mechanical properties and improved performance , easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

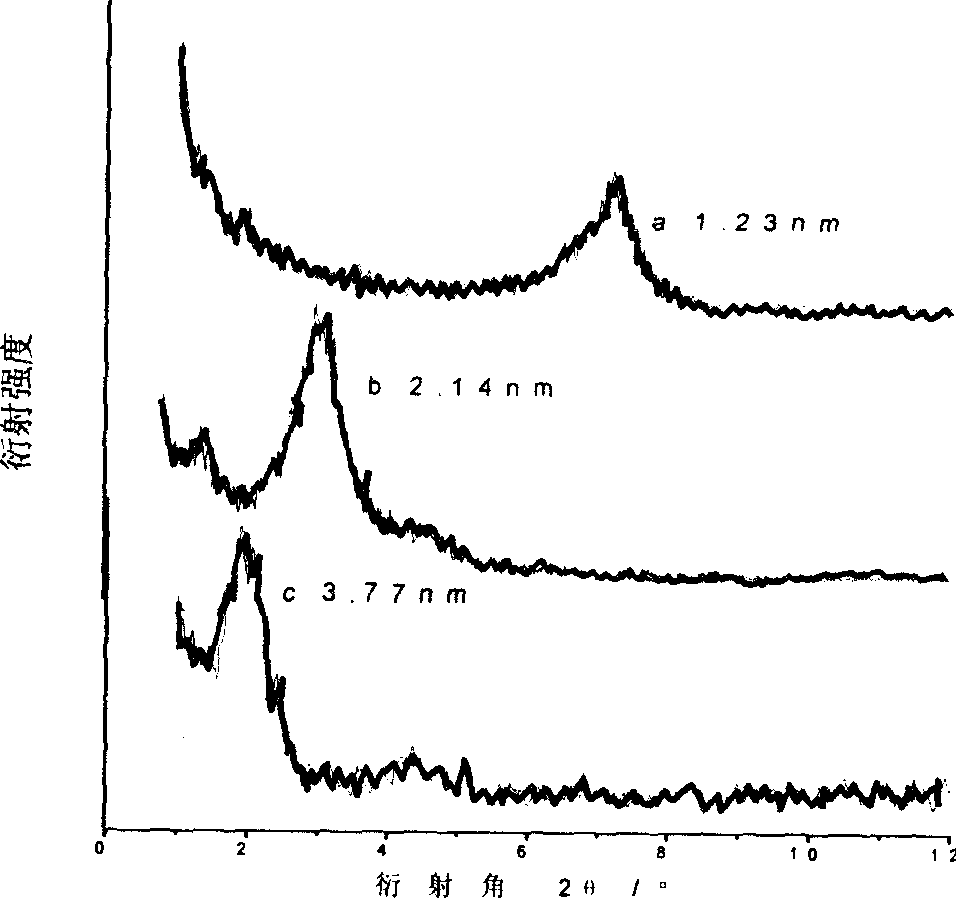

[0046] Embodiment 1 Preparation of organomontmorillonite

[0047] First, add 10.0g of sodium montmorillonite to 300ml of water, stir and heat up to 70°C to form a water dispersion, then add 100ml of 5.4g of octadecyltrimethylammonium chloride (OTAC, Guangzhou Lizhong Industry and Trade Co., Ltd. ) aqueous solution was added to the aqueous dispersion of sodium montmorillonite, and stirred at 70°C for 20h. Let it cool down to room temperature, discharge, filter and wash to remove impurities 3-5 times, until the filtrate is tested to be free of chloride ions with silver nitrate, then dried at 80°C to constant weight and finely ground to obtain a white powdery organic montmorillonite Soil removal (OMMT).

[0048] Preparation of phenolic epoxy resin / organic montmorillonite nanocomposite flame retardant masterbatch

[0049] 100g novolac epoxy resin was heated up to 70°C, 5g organic montmorillonite (OMMT) and 0.5g silane coupling agent KH560 were added, and stirred for 2 hours to o...

Embodiment 2

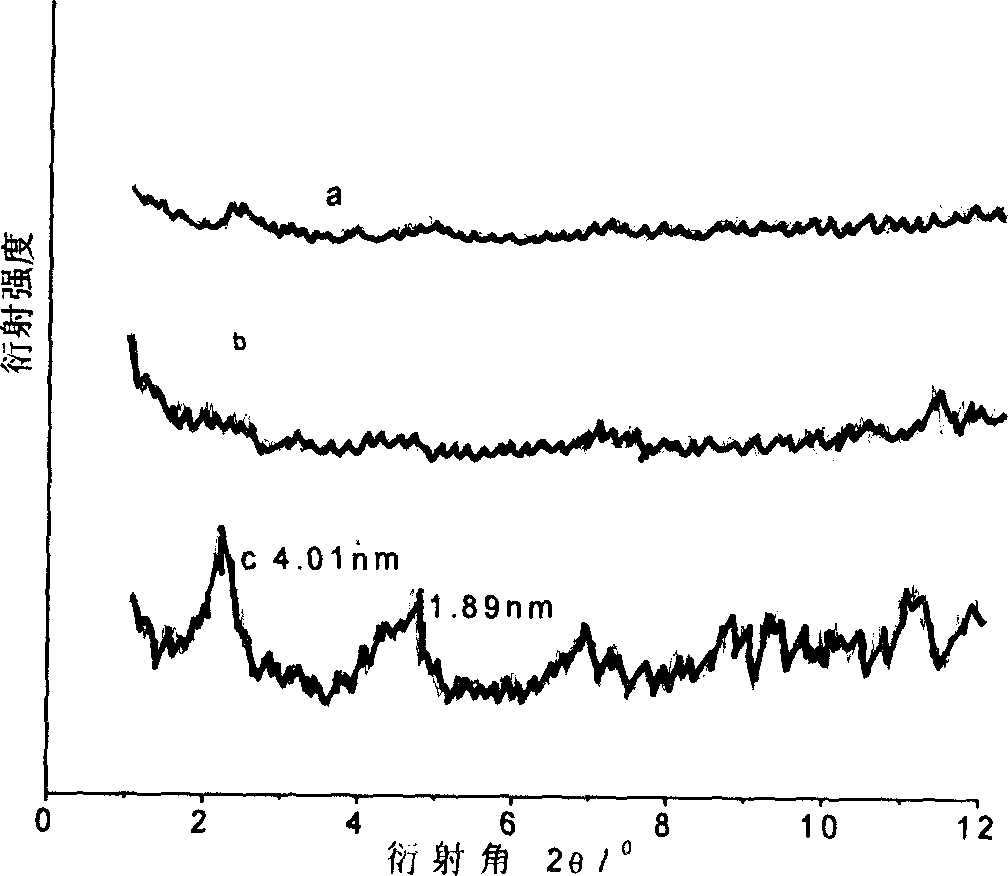

[0056] The preparation method and reaction conditions of NER / OMMT nano composite flame retardant master batch of the present invention are as embodiment 1, keep the mass ratio (2: 1) and total consumption (20wt%) of NER / OMMT nano composite flame retardant master batch and TPP Change the mass ratio of organic montmorillonite and novolac epoxy resin in the flame retardant masterbatch, the effect of the mass ratio of organic montmorillonite to novolac epoxy resin on the oxygen index and mechanical properties of flame retardant PP is shown in Table 2 . It can be seen that when the mass ratio of OMMT to novolac epoxy resin is 5:100, the oxygen index of flame-retardant PP is the highest, and the comprehensive mechanical properties are the best; when the mass ratio of OMMT to novolac epoxy resin exceeds 5:100, the oxygen index And the mechanical properties decrease instead. When the amount of OMMT is appropriate, it is beneficial for the novolac epoxy resin to enter the OMMT layer, ...

Embodiment 3

[0060] The preparation method and reaction conditions of NER / OMMT nanocomposite flame retardant masterbatch of the present invention are as embodiment 1, keep the mass ratio (100:5) of novolac epoxy resin and organic montmorillonite and NER / OMMT nanocomposite flame retardant masterbatch The total consumption (20wt%) of material and TPP is constant, changes the mass ratio of NER / OMMT nano composite flame retardant masterbatch and PP, the mass ratio of gained NER / OMMT nanocomposite flame retardant masterbatch and TPP is compared to the oxygen of flame retardant PP The effects of indices and mechanical properties are shown in Table 3. It can be seen that the use of NER / OMMT nanocomposite flame retardant masterbatch or TPP alone cannot achieve a good flame retardant effect. As the proportion of NER / OMMT increases, the oxygen index of flame retardant PP increases first and then decreases. trend. Considering the flame retardancy and mechanical properties comprehensively and combini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com