Polypropylene material for car bumper and preparation method of polypropylene material

A technology for polypropylene materials and automobile bumpers, which is applied in the field of polypropylene materials and its preparation, can solve problems such as poor impact resistance of bumpers, and achieve the effects of enhancing interface compatibility, moderate spacing, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

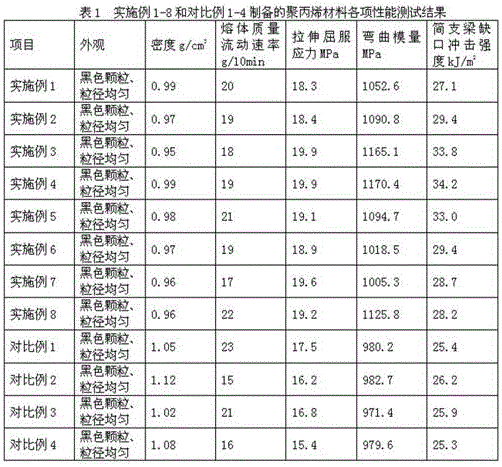

Examples

Embodiment 1

[0023] A polypropylene material for automobile bumper, comprising the following raw materials in parts by weight: 50 parts of isotactic polypropylene, 30 parts of EPDM, 7.5 parts of modified wollastonite powder, 2.5 parts of modified glass fiber, 0.5 part of antioxidant 1010, silane 0.2 parts of coupling agent KH550, 0.1 parts of ultraviolet absorber UV-P and 2 parts of microcrystalline paraffin.

[0024] The length-to-diameter ratio of the modified wollastonite is 15:1, and its preparation method is to add 0.5wt% aluminate coupling agent DL-411D based on the weight of wollastonite powder to wollastonite powder, and then at 125°C Stir with a high-speed mixer for 30 minutes at a speed of 1000r / min, and obtain modified wollastonite powder after cooling;

[0025] The preparation method of the modified glass fiber is to add 1wt% aluminate coupling agent DL-411D based on the weight of the glass fiber to the glass fiber, and then stir it with a high-speed mixer at 125°C for 20min at...

Embodiment 2

[0030] A polypropylene material for an automobile bumper, comprising the following raw materials in parts by weight: 80 parts of isotactic polypropylene, 20 parts of POE, 24 parts of modified wollastonite powder, 6 parts of modified glass fiber, 0.1 part of antioxidant DLTP, 0.6 parts of silane coupling agent KH570, 0.3 parts of ultraviolet absorber UV-9 and 9 parts of magnesium stearate.

[0031] The length-to-diameter ratio of the modified wollastonite is 18:1, and its preparation method is to add 1.5wt% aluminate coupling agent DL-411D based on the weight of wollastonite powder to wollastonite powder, and then Stir with a high-speed mixer for 20 minutes at a speed of 1200r / min, and obtain modified wollastonite powder after cooling;

[0032] The preparation method of the modified glass fiber is to add 2wt% aluminate coupling agent DL-411D based on the weight of the glass fiber to the glass fiber, and then stir with a high-speed stirrer at 135°C for 30min at a speed of 1200r / ...

Embodiment 3

[0037] A polypropylene material for automobile bumper, comprising the following raw materials in parts by weight: 65 parts of isotactic polypropylene, 25 parts of EPDM, 15 parts of modified wollastonite powder, 5 parts of modified glass fiber, 0.3 part of antioxidant 168, 0.4 parts of titanate coupling agent 131, 0.2 parts of ultraviolet absorber UV-531 and 5 parts of microcrystalline paraffin.

[0038] The length-to-diameter ratio of the modified wollastonite is 17:1, and its preparation method is to add 1wt% aluminate coupling agent DL-411D based on the weight of wollastonite powder to wollastonite powder, and then at 130°C Stir with a high-speed mixer for 25 minutes at a speed of 1100r / min, and obtain modified wollastonite powder after cooling;

[0039] The preparation method of the modified glass fiber is to add 1.5wt% aluminate coupling agent DL-411D based on the weight of the glass fiber to the glass fiber, and then stir it with a high-speed mixer at 130°C for 25min at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com