Preparation method of wide-temperature-range and high-damping rubber and plastic blended foam material

A technology of foaming materials and high damping, which is applied in the field of preparation of rubber-plastic blended foaming materials with wide temperature range and high damping, can solve the problems of not combining its own viscoelasticity with porous structure, so as to broaden the damping temperature range and improve Excellent damping factor and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Aiming at the problems of low effective damping temperature range and poor sound insulation effect of high-damping rubber-plastic blended foaming materials in the prior art, the present invention provides a preparation method of wide-temperature-range high-damping rubber-plastic blended foaming materials, including Follow the steps below:

[0035] (1) Internal mixer is used for the first stage of mixing, the initial temperature is set at 150-180°C, the rotor speed is 40-60r / min, polylactic acid is added first, and then ethylene-vinyl acetate rubber and white carbon black are mixed. Refining, the mass fraction ratio is 10-40 parts of polylactic acid: 60-90 parts of ethylene-vinyl acetate: 20-80 parts of white carbon black, timing and mixing for 10-20 minutes from the time of adding materials, and then discharging glue, the ethylene- The vinyl acetate content of vinyl acetate rubber is 70%; the second-stage mixing adopts a double-roll mill, and at room temperature, 1-4 pa...

Embodiment 1

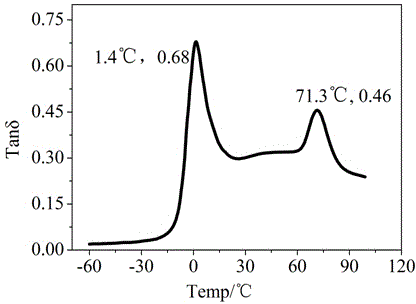

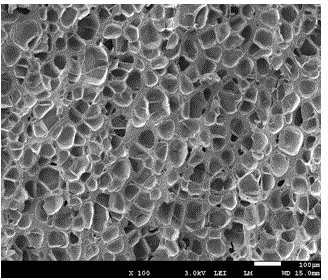

[0054] HAAKE torque rheometer is used in the internal mixing room, the initial temperature is set at 160°C, the rotor speed is 50r / min, 20 grams of PLA is first put into the internal mixing room, mixed for 1 minute, 80 grams of EVM700 is added, and mixed 1 minute, add 30 grams of white carbon black in two parts, and then knead for 10 minutes to remove the glue; then use a double-roller open mill to add 2 grams of zinc oxide and 1 gram of stearin to the mixed rubber at room temperature. Acid, 4 grams of AC foaming agent, 6 grams of vulcanizing agent BIPB, thin pass 5 times of tableting, made the rubber compound a. After the mixed rubber a was left to stand for 16 hours, it was vulcanized and foamed with a flat vulcanizer. The mold pressure was 10 MPa, the vulcanization and foaming temperature was 170°C, and the vulcanization and foaming time was 2 minutes. The effective damping temperature with uniform cells can be obtained. Wide temperature range high damping blend material wi...

Embodiment 2

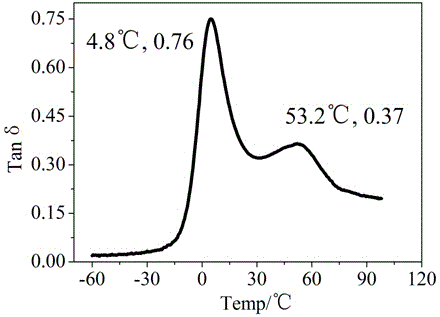

[0057] HAAKE torque rheometer is used in the internal mixing room, the initial temperature is set at 160°C, the rotor speed is 50r / min, 30 grams of PLA is first put into the internal mixing room, mixed for 1 minute, 70 grams of EVM700 is added, and mixed 1 minute, add 40 grams of white carbon black in two parts, and then knead for 10 minutes to remove the glue; then use a double-roller mill to add 1 gram of zinc oxide and 0.5 gram of stearin to a section of mixed rubber at room temperature. Acid, 2 grams of AC foaming agent, 9 grams of BIPB vulcanizing agent, thin pass 8 times of tableting, made rubber compound a. After the mixed rubber a was left to stand for 8 hours, it was vulcanized and foamed with a flat vulcanizer. The mold pressure was 10 MPa, the vulcanization and foaming temperature was 170°C, and the vulcanization and foaming time was 3 minutes. Wide temperature range high damping blend material with a temperature range of 87°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com