Preparation process of boron-containing bene oxazine resin

A benzoxazine and resin technology, applied in the field of boron-containing benzoxazine resin and its preparation, can solve the problems of large void ratio of products, poor molding processability, poor solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

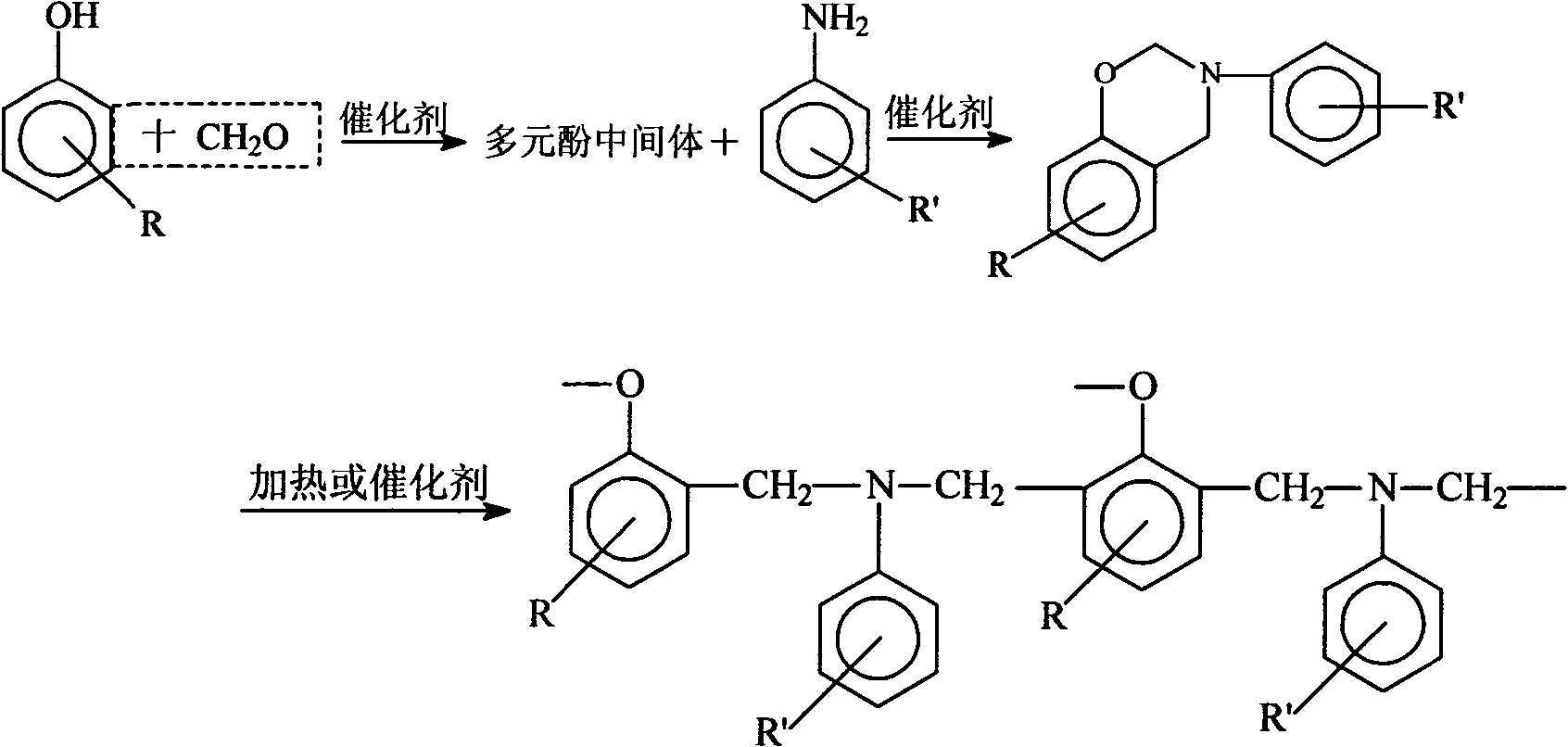

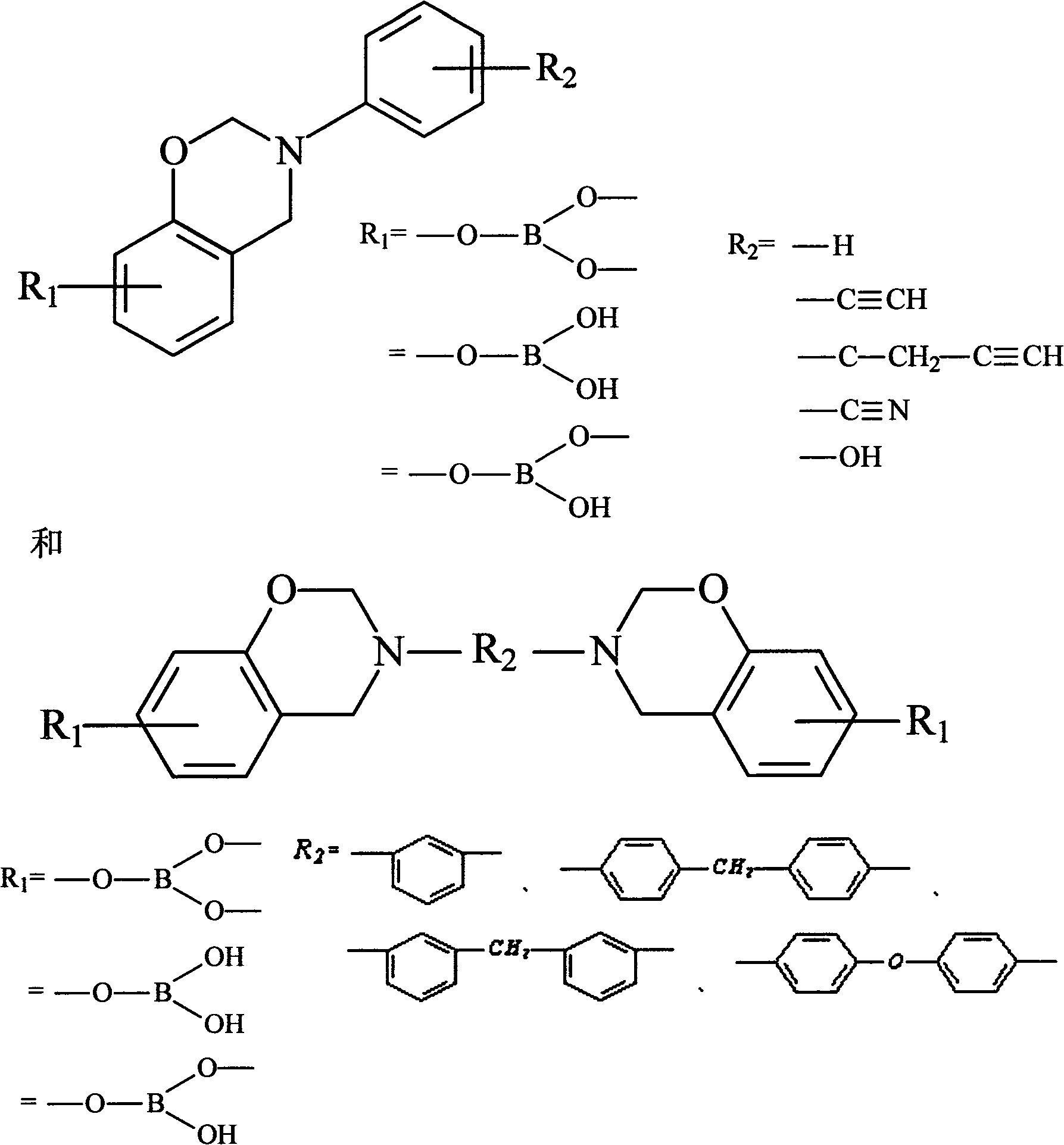

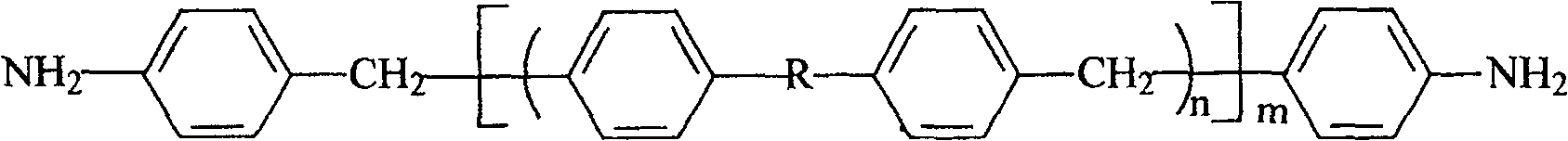

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Add 20 parts of boric acid and 80 parts of phenol into the reaction kettle, heat up (not exceeding 160° C.) for dehydration, and cool down when the desorbed water reaches a certain amount, then add 160 parts of formaldehyde aqueous solution, and use an alkaline catalyst Adjust the pH value of the system to 6-10, add toluene and 40 parts of ethylenediamine to carry out temperature rise and reflux reaction for 2 hours, then vacuum dehydrate at 80-140°C to obtain boron-containing benzoxazine resin, add solvent to obtain uniform and clear Transparent brown-yellow stable solution of boron-containing benzoxazine resin. The resin solution can be added with an accelerator according to different purposes to adjust the molding time to 5-18min / 160°C.

Embodiment 2

[0062] Example 2: Add 70 parts of boric acid and 240 parts of phenol into the reaction kettle, heat up (not exceeding 160°C) for dehydration, cool down and cool down when the detached water reaches a certain amount, then add 360 parts of formaldehyde aqueous solution, adjust with alkaline catalyst The pH value of the system is 6-10, add toluene, 120 parts of 4,4'diaminodiphenylmethane (MDA) to carry out temperature rise and reflux reaction for 4 hours, then vacuum dehydrate at 80-140°C to obtain boron-containing benzoxazine The resin is added with a solvent to obtain a stable solution of a uniform, clear, transparent brown-yellow boron-containing benzoxazine resin. The resin solution can be added with an accelerator according to different purposes to adjust the molding time to 5-18min / 160°C.

Embodiment 3

[0063] Example 3: Add 70 parts of boric acid and 240 parts of phenol into the reaction kettle, heat up (not exceeding 160°C) for dehydration, cool down when the desorbed water reaches a certain amount, then add toluene and 160 parts of formaldehyde aqueous solution, and use an acidic catalyst Adjust the pH value of the system to 1-3, heat up and reflux for 2 hours and then lower the temperature, adjust the pH value of the system to 6-10 with an alkaline catalyst, add 120 parts of aniline, 200 parts of formaldehyde aqueous solution and a small amount of toluene and alcohol, and heat up at 80 After reflux reaction at ~90°C for 2 hours, vacuum dehydration at 80-120°C to obtain a boron-containing benzoxazine resin, adding a solvent to obtain a uniform, clear, transparent brown-red stable solution of the boron-containing benzoxazine resin. The resin solution can be added with an accelerator according to different purposes to adjust the molding time to 5-18min / 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com