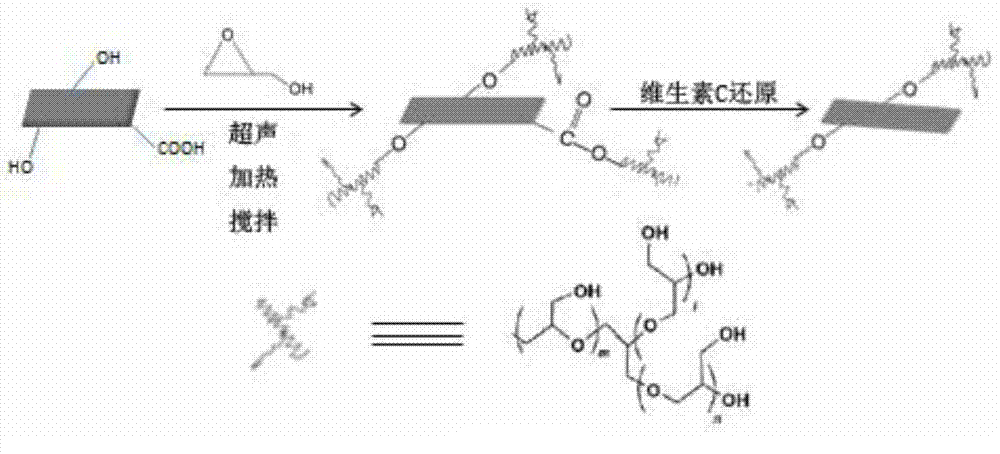

Highly water-dispersible hyperbranched polyglycerol surface-modified graphene preparation method

A technology of surface modification and polyglycerol, which is applied in the field of preparation of nanocomposite materials, can solve problems such as cumbersome steps, potential safety hazards, and complicated operations, and achieve the effects of improving water dispersibility, preventing irreversible agglomeration, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

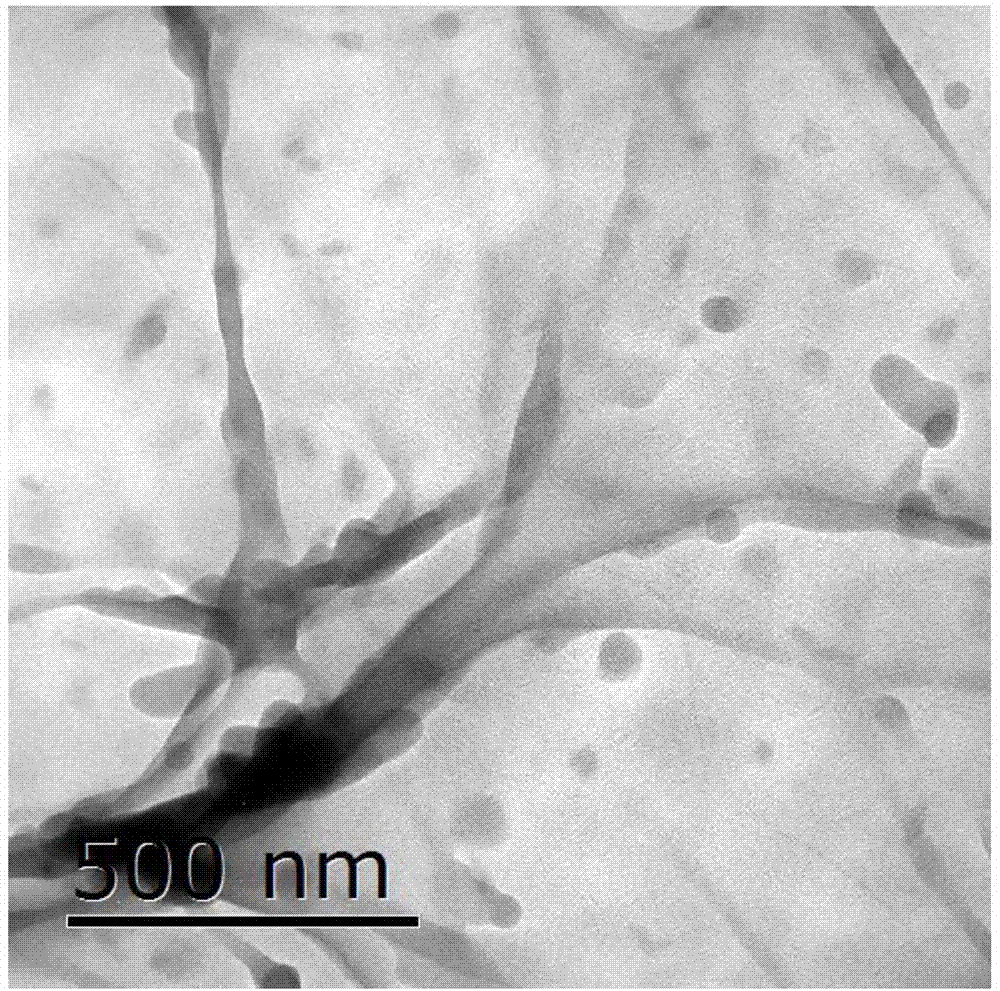

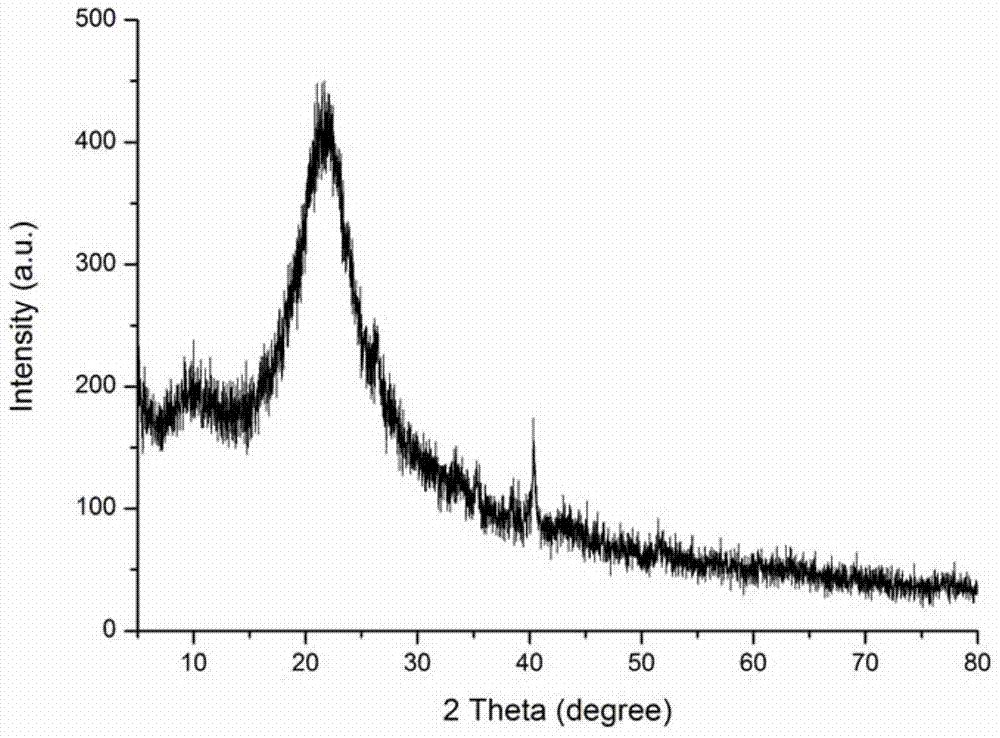

[0024] Mix 50 mg of dry graphite oxide powder prepared by the modified Hummers method with 7 mL of glycidol with a purity of 96%, and disperse ultrasonically for 1 hour at room temperature under ultrasonic conditions with a power of 500 W; Pour the solution into a 25mL round-bottomed flask, place the round-bottomed flask in an oil bath at 100°C, pass through nitrogen to isolate the air, and stir for 10 hours using magnetic force; after cooling the finally obtained bright black colloidal solution to room temperature naturally, add 50mL of anhydrous methanol, sonicated in a water bath for 10min, then added 100mL of acetone into the solution, after standing for a while, a black solid precipitated out of the solution, and the supernatant was discarded to obtain a black solid. After this washing process was repeated 3 times, the black solid was vacuum-dried at room temperature for 8 hours to obtain a black powder, which was ultrasonicated in a water bath for 5 minutes, and all of it...

Embodiment 2

[0026] Mix 100 mg of dry graphite oxide powder prepared by the modified Hummers method with 10 mL of glycidol with a purity of 96%, and disperse ultrasonically for 2 hours at room temperature under ultrasonic conditions with a power of 500 W; Pour the solution into a 25mL round-bottomed flask, place the round-bottomed flask in an oil bath at 110°C, pass through nitrogen to isolate the air, and stir for 15 hours using a magnetic force; after cooling the finally obtained bright black colloidal solution to room temperature naturally, use 100mL of anhydrous methanol, sonicated in a water bath for 15min, then added 200mL of acetone into the solution, after standing for a while, a black solid precipitated out of the solution, and the supernatant was discarded to obtain a black solid. After this washing process was repeated 3 times, the black solid was vacuum-dried at room temperature for 9 hours to obtain a black powder, which was uniformly dispersed in 100 mL of water by ultrasonica...

Embodiment 3

[0029] Mix 150 mg of dry graphite oxide powder prepared by the modified Hummers method with 15 mL of glycidol with a purity of 96%, and disperse ultrasonically for 1 hour at room temperature under ultrasonic conditions with a power of 500 W; Pour the solution into a 25mL round-bottomed flask, place the round-bottomed flask in an oil bath at 120°C, pass through nitrogen to isolate the air, and stir for 17 hours using a magnetic force; after cooling the finally obtained bright black colloidal solution to room temperature naturally, use 150mL of anhydrous methanol, sonicate in a water bath for 20min, then add 300mL of acetone into the solution, after standing for a while, a black solid precipitates out of the solution, pour off the supernatant to obtain a black solid. After this washing process was repeated 3 times, the black solid was vacuum-dried at room temperature for 10 hours to obtain a black powder, which was uniformly dispersed in 150 mL of water by ultrasonication in a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com