Normal-temperature curing type flame-retardant anti-cracking low-halogen epoxy pouring sealant for automotive ignition coil

A car ignition coil, curing technology at room temperature, applied in the field of polymer chemistry, can solve the problems of increased energy consumption, poor resistance to cracking and heat and humidity, and large internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

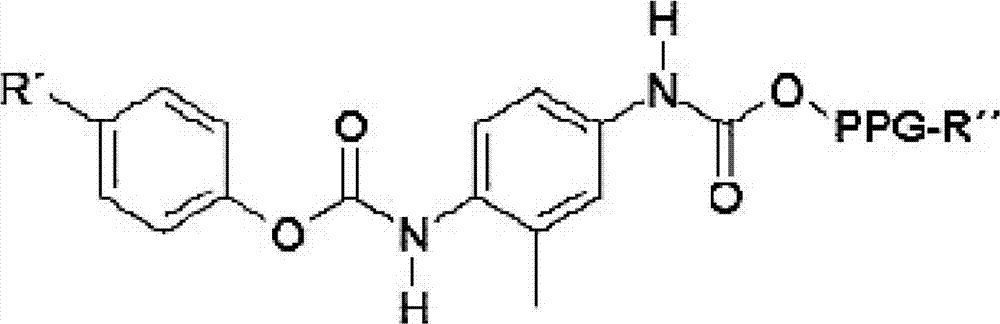

[0025] A normal temperature curing flame-retardant anti-cracking low-halogen epoxy potting adhesive for automobile ignition coils, including component A and component B, the component A includes epoxy resin, active polyurethane toughening agent, diluent, hydrogen Alumina and aluminum oxide; the B component includes alicyclic amine curing agent and polyether amine curing agent.

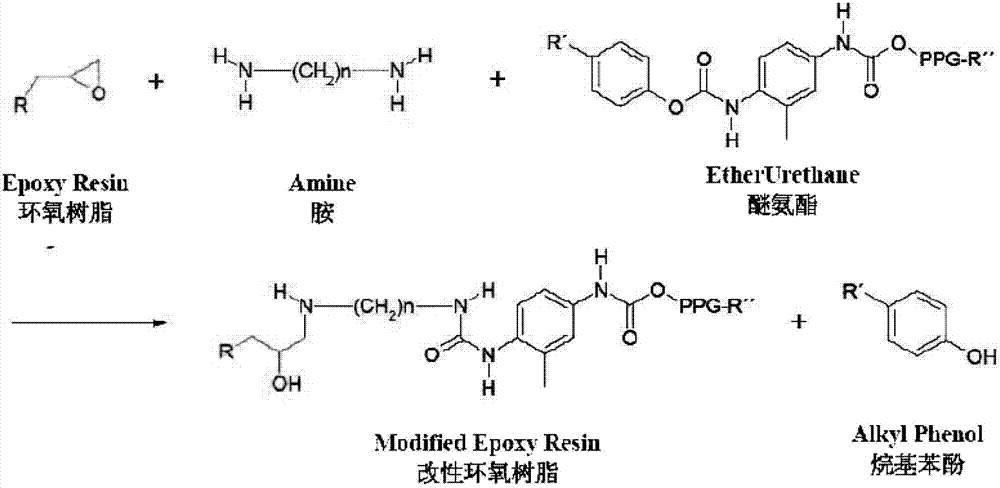

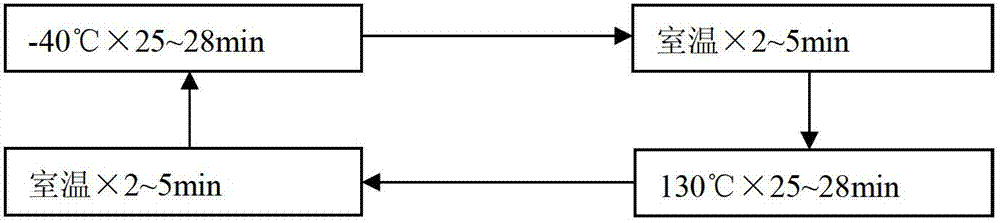

[0026] A method for preparing a normal temperature curing flame-retardant anti-cracking low-halogen epoxy potting adhesive for automobile ignition coils. The principle is as follows: figure 2 Shown:

[0027] A. Preparation of Component A

[0028] By weight, mix 20 parts of epoxy resin, 5 parts of active polyurethane toughening agent, 5 parts of diluent, etc., and put 20 parts of aluminum hydroxide and 10 parts of aluminum oxide after drying at 120 ° C for 2 hours while hot, Stir in a high-speed disperser for 30 minutes to disperse the glue evenly, then grind and disperse in a ball mill, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com