Natural building exterior wall coating

A pure natural technology for building exterior walls, applied in the field of building exterior wall coatings, can solve the problems of many chemical components, poor water resistance, coating shrinkage and other problems, achieve outstanding economic benefits, low prices, and improve the effect of waterproof and anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The inventive method implements according to the following steps:

[0013] (1) Use a pulverizer to crush white stone powder and alum into fine particles.

[0014] (2) Mix white cement and lime paste and put them into the mixer, then put crushed white stone powder and alum in a certain proportion, then add rubber tree sap and stir evenly.

[0015] (3) The mixed dry solid after stirring and discharging is then prepared into a thick liquid finished product through the steps of adding water and coloring material.

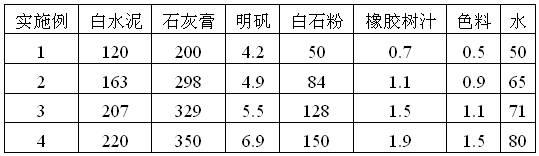

[0016] The parts by weight of raw materials used in the product embodiment 1 to embodiment 4 of the present invention are shown in Table 1, and the unit is kg.

[0017] Table 1

[0018]

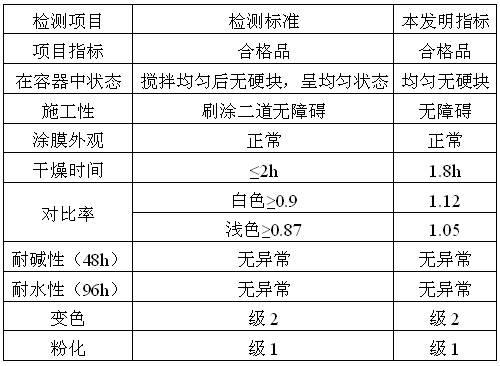

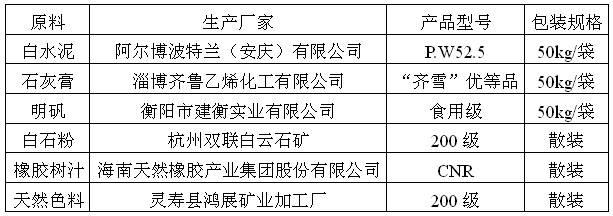

[0019] The sources of raw materials used in Examples 1 to 4 are shown in Table 2.

[0020] Table 2

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com