Preparing method of high-purity carbon dioxide

A carbon dioxide, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of polluting the environment, reducing the economic value of aquatic products, and not being utilized, achieving high calcium carbonate content and solving shell pollution , the effect of creating economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

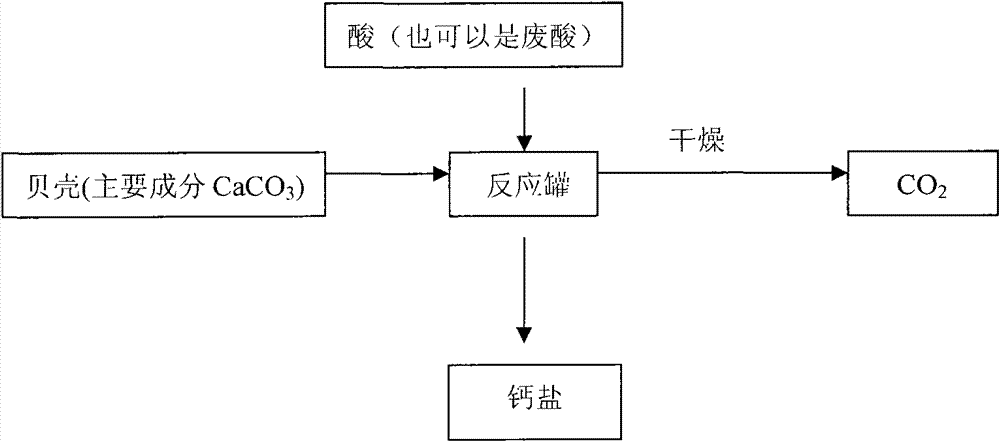

[0018] High-purity carbon dioxide is prepared by reacting shells with pure hydrochloric acid. The specific reaction formula is as follows:

[0019] CaCO 3 +2HCl=CaCl 2 +CO 2 +H 2 o

[0020] Concrete preparation process: raw material hydrochloric acid: mass concentration is 30%; Shell (wherein CaCO 3 Content: 94% by weight); shells include all shells, such as oyster shells, clam shells, conch shells, scallop shells, abalone shells, single species of shells or mixed species of shells.

[0021] First, remove the soil and other sundries on the surface of the shells with clean water, and then crush them. The powdered shell powder is stored separately for later use. The particle size of the shells after crushing is controlled at 16-20 mesh, because the particle size is too large, stir during the reaction Inconvenient, the particle size is too small and will be ejected by air bubbles during the reaction. Take 1.06t shell particles (containing CaCO 3 1t) into the reactor, add 2...

Embodiment 2

[0024] Shells react with acetic acid

[0025] 2CH 3 COOH+CaCO 3 =(CH 3 COO) 2 Ca+H 2 O+CO 2

[0026] Raw materials: acetic acid: mass concentration 99%; shells: CaCO 3 Content 94% weight percent (with embodiment 1);

[0027] Adopt the preparation method described in embodiment 1, the specific ratio of raw materials is as follows: adopt 1.06t shell (containing CaCO 3 1t) consume 1.21t of 99% acetic acid, obtain 0.44t carbon dioxide gas, and crystallize to obtain 1.58t (CH 3 COO) 2 Ca·H 2 O and 0.01t water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com