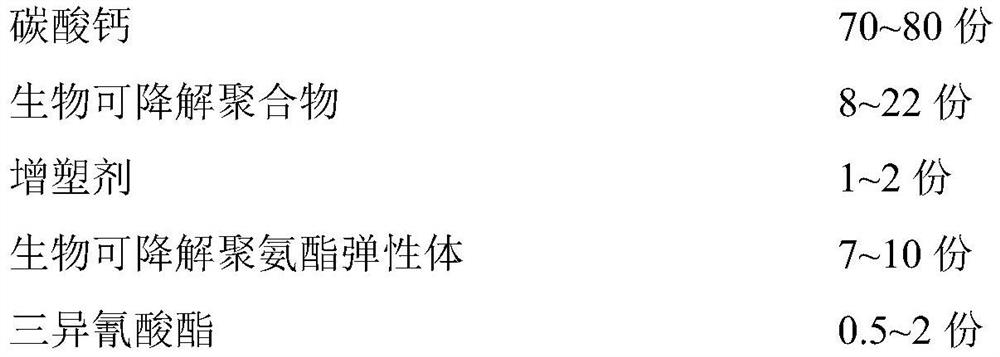

A kind of calcium carbonate highly filled biodegradable film and preparation method thereof

A technology of biodegradation and biodegradation of polyester, which is applied in the field of calcium carbonate highly filled biodegradable film and its preparation, can solve the problems of calcium carbonate easy to agglomerate and the performance degradation of film products, and achieve good material performance, increase content and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

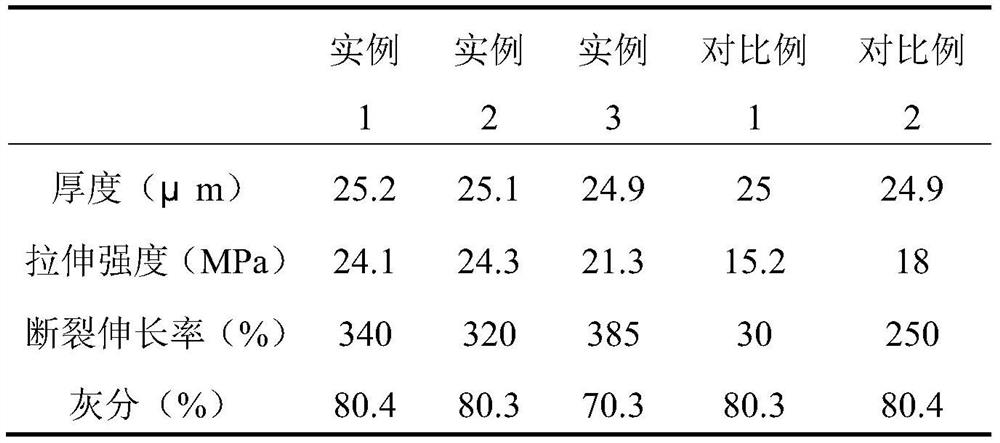

Examples

Embodiment 1

[0035] A calcium carbonate highly filled biodegradable film and a preparation method thereof, the steps are as follows:

[0036] 1) Select 80kg of 6000 mesh calcium carbonate and dry it at 100°C for 2 hours;

[0037] 2) The calcium carbonate obtained in step 1) and 1.6 kg of triphenylmethane triisocyanate were stirred and mixed in a high-speed mixer at a temperature of 100° C., and mixed for 30 minutes to obtain activated calcium carbonate;

[0038] 3) Calcium carbonate after the activation obtained in step 2), polybutylene succinate, 1.339kg 4,4-diphenylmethane diisocyanate and 0.584kg chain extender according to the setting The ratio is molded into a molten material by means of an internal mixer, the mixing time is 1 hour, and the temperature is 190 ° C, and then compression molded into a sheet, cooled and cut to obtain a polyurethane elastomer filled with calcium carbonate;

[0039] 4) The polyurethane elastomer highly filled with calcium carbonate obtained in step 3), 8 k...

Embodiment 2

[0042] A calcium carbonate highly filled biodegradable film and a preparation method thereof, the steps are as follows:

[0043] 1) Select 80kg of 6000 mesh calcium carbonate and dry it at 100°C for 2 hours;

[0044] 2) The calcium carbonate obtained in step 1) and 1.6 kg of triphenylmethane triisocyanate were stirred and mixed in a high-speed mixer at a temperature of 100° C., and mixed for 30 minutes to obtain activated calcium carbonate;

[0045] 3) The activated calcium carbonate obtained in step 2), 6.433kg of polybutylene succinate, 1.387kg of 4,4-dicyclohexylmethane diisocyanate and 0.58kg of chain extender according to the set The ratio is molded into a molten material by means of an internal mixer, the mixing time is 1 hour, and the temperature is 190 ° C, and then compression molded into a sheet, cooled and cut to obtain a polyurethane elastomer filled with calcium carbonate;

[0046] 4) The polyurethane elastomer highly filled with calcium carbonate obtained in step ...

Embodiment 3

[0049] A calcium carbonate highly filled biodegradable film and a preparation method thereof, the steps are as follows:

[0050] 1) Select 70kg of 5000 mesh calcium carbonate and dry it at 100°C for 2 hours;

[0051] 2) The calcium carbonate obtained in step 1) and 1.05kg L-lysine triisocyanate were stirred and mixed in a high-speed mixer at a temperature of 100° C., and mixed for 30 minutes to obtain activated calcium carbonate;

[0052] 3) calcium carbonate after the activation obtained in step 2), polybutylene terephthalate, 0.793kg 4,4-diphenylmethane diisocyanate and 0.426kg chain extender according to design Molded into a molten material by mixing with a mixer at a fixed ratio, the mixing time is 1.5h, the temperature is 170°C, and then compression molded into a sheet, cooled and cut to obtain a polyurethane elastomer filled with calcium carbonate;

[0053] 4) Cast the polyurethane elastomer highly filled with calcium carbonate obtained in step 3), 10kg PLA, 12kg PBAT, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com