Mounting structure and nanoparticle mounting material

A technology of nano-particles and installation materials, which is applied in the direction of nano-technology, nano-technology, and nano-technology for information processing. The effect of suppressing generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

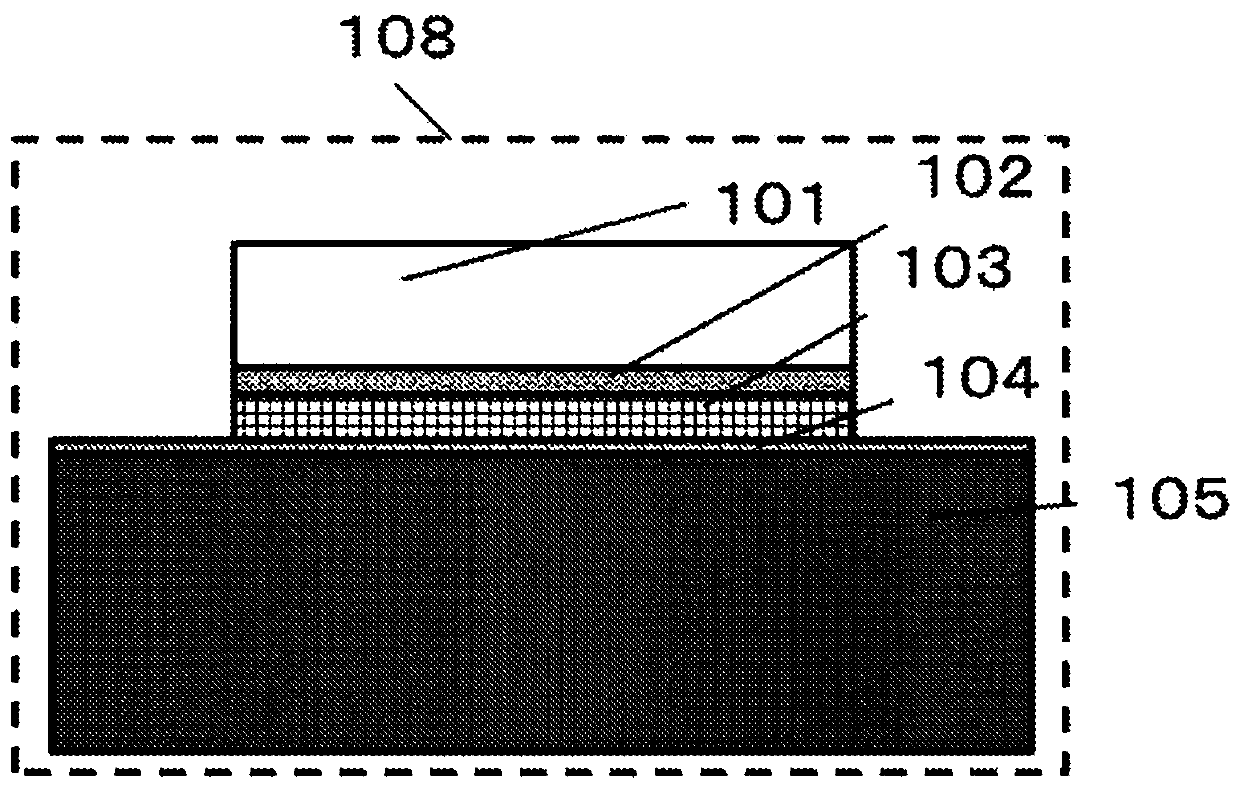

[0060] 1. Fabrication of installation structure

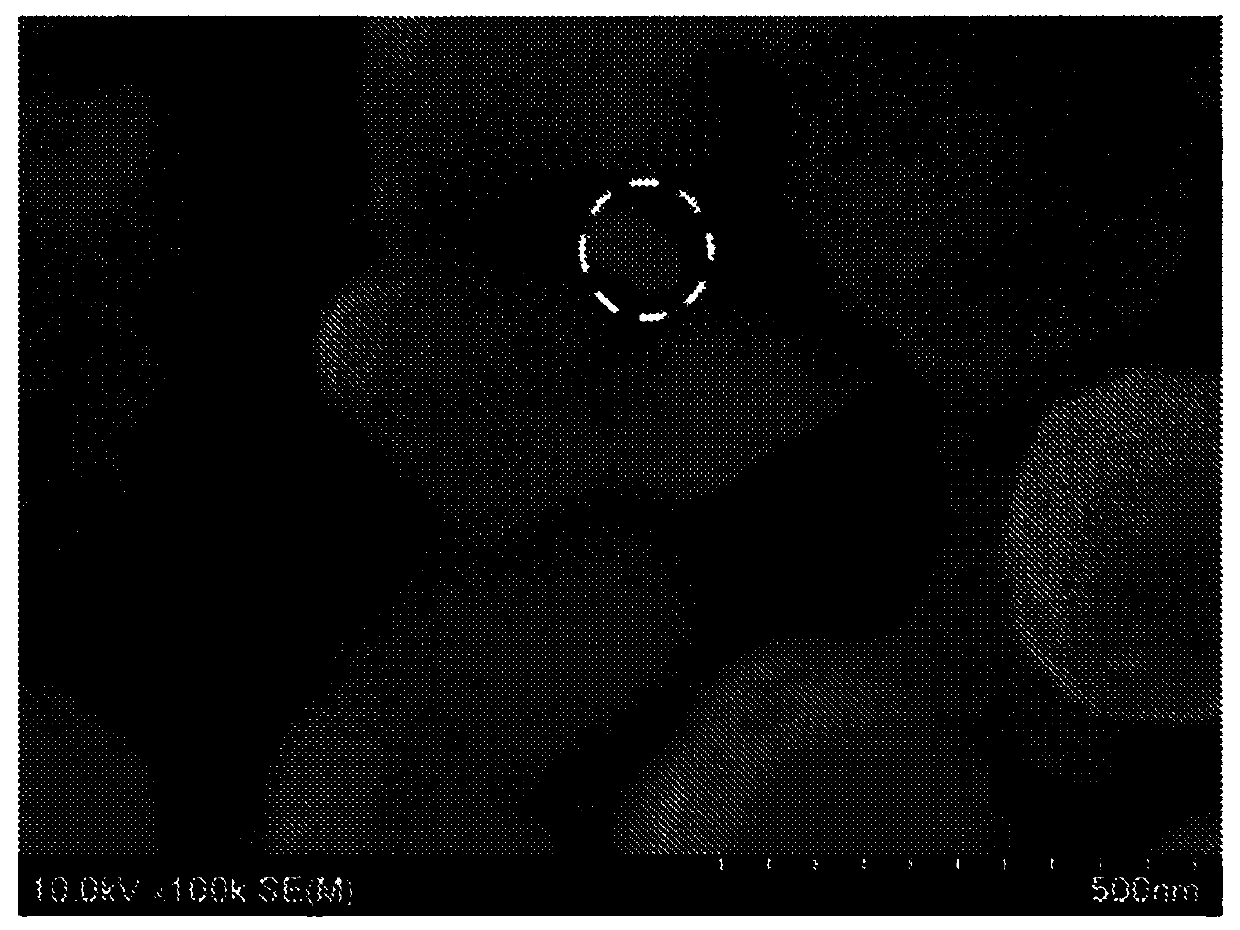

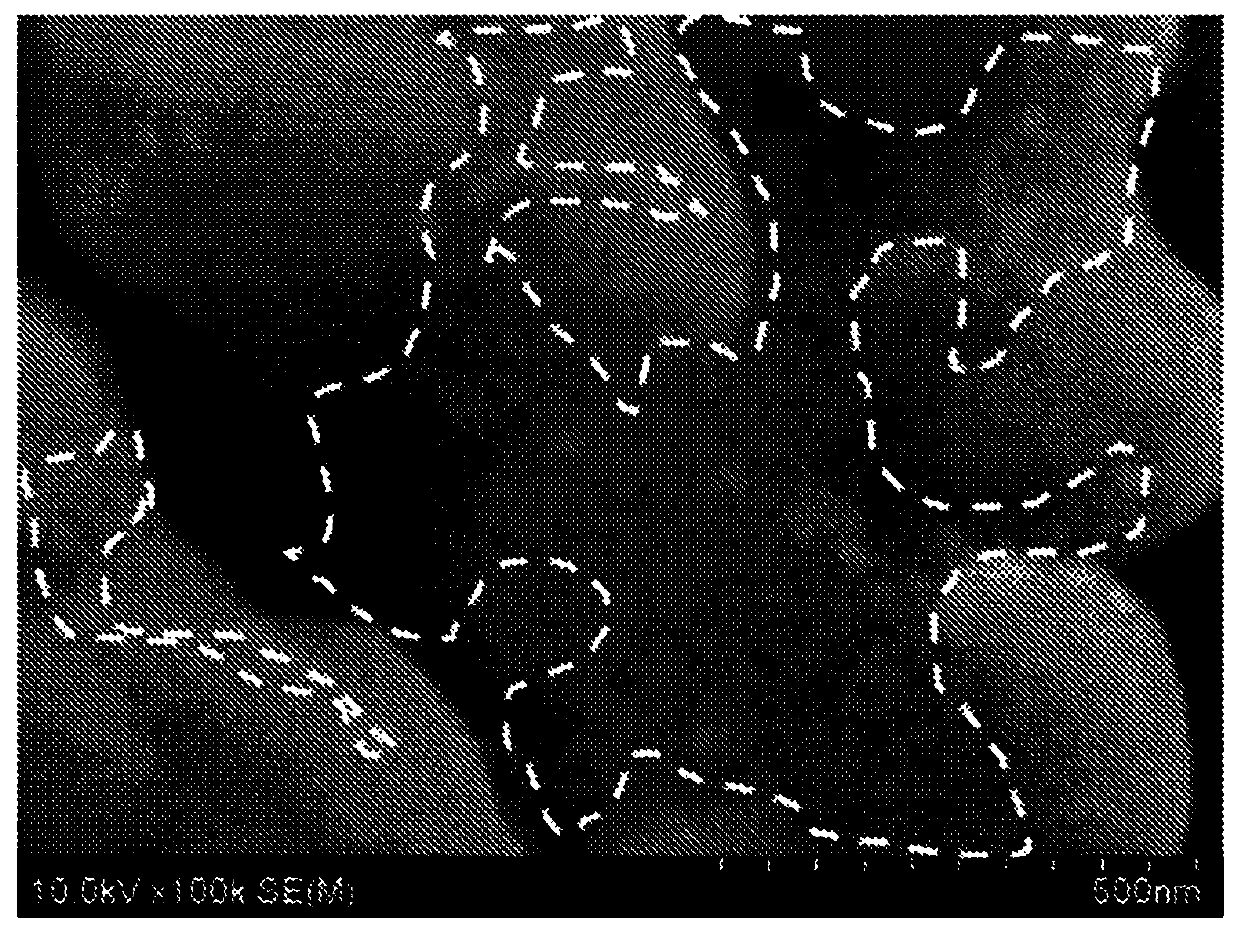

[0061] Separately, prepare Ag nanoparticles with an average particle diameter of 100 nm as nanoparticles of the first metal, prepare Sn nanoparticles with an average particle diameter of 100 nm, Sb nanoparticles with an average particle diameter of 100 nm, and Pd nanoparticles with an average particle diameter of 100 nm. Nanoparticles, come as nanoparticles of the second metal. When the nanoparticles of the first metal were observed with a scanning electron microscope (SEM), the ratio of nanoparticles having a particle size of 100 nm or less was 50% relative to the number of observed nanoparticles of the first metal.

[0062] The total amount of nanoparticles of the first metal and nanoparticles of the second metal is 70% by mass, the amount of polyethylene glycol (average molecular weight is 200) as the organic solvent is 29% by mass, and the amount of the dispersant and the reducing agent is The total amount was 1% by mass, ...

Embodiment 2

[0087] In Example 2, except having used Cu, Pb, and Ge as the second metal, it carried out similarly to Example 1, and produced and evaluated the mounting structure.

[0088] In addition, the diffusion coefficient of Cu in Ag at 200°C is 10 -17 m 2 On the order of / sec, the diffusion coefficient of Pb in Ag at 200°C is 10 -22 m 2 On the order of / sec, the diffusion coefficient of Ge in Ag at 200°C is 10 -22 m 2 The magnitude of / sec. Each of these diffusion coefficients is greater than the self-diffusion coefficient of Ag in Ag at 200°C.

[0089] In addition, the compounding ratio of the nanoparticles of the second metal is adjusted so that the mass of Cu, Pb, and Ge relative to the total mass of Ag becomes half of the solid solution limit at 200°C in the equilibrium diagram of Ag and each element .

[0090] Table 2 shows the types of the first metal and the second metal in Example 2, and the second metal relative to the total mass of the nanoparticles of the first meta...

Embodiment 3

[0097] In Example 3, except having used Cu as the first metal and Ge as the second element, it carried out similarly to Example 1, and produced and evaluated the mounting structure.

[0098] In addition, the diffusion coefficient of Ge in Cu at 200°C is 10 -23 m 2 On the order of / sec, the self-diffusion coefficient of Cu in Cu at 200°C is 10 -29 m 2 The magnitude of / sec. The diffusion coefficient of Ge in Cu at 200°C is larger than the self-diffusion coefficient of Cu in Cu at 200°C.

[0099] In addition, the compounding ratio of the nanoparticles of the second metal (Ge) was adjusted so that the mass of Ge relative to the total mass of Cu was half of the solid solution limit at 200° C. in the equilibrium diagram of Cu and Ge.

[0100] Table 3 shows the types of the first metal and the second metal in Example 3, and the second metal relative to the total mass of the nanoparticles of the first metal (Cu) and the nanoparticles of the second metal (Ge). The mass ratio (con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com