Outer heat insulating wall body for mechanically anchoring grid reinforcing rib mineral wool plate and construction process thereof

A grid strengthening, mineral wool board technology, applied in thermal insulation, wall, building structure and other directions, can solve the hidden dangers of quality and safety and stability, increase the quality and safety and stability of the leveling layer, etc., to achieve easy control of construction quality, The effect of reducing the construction process and construction period, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

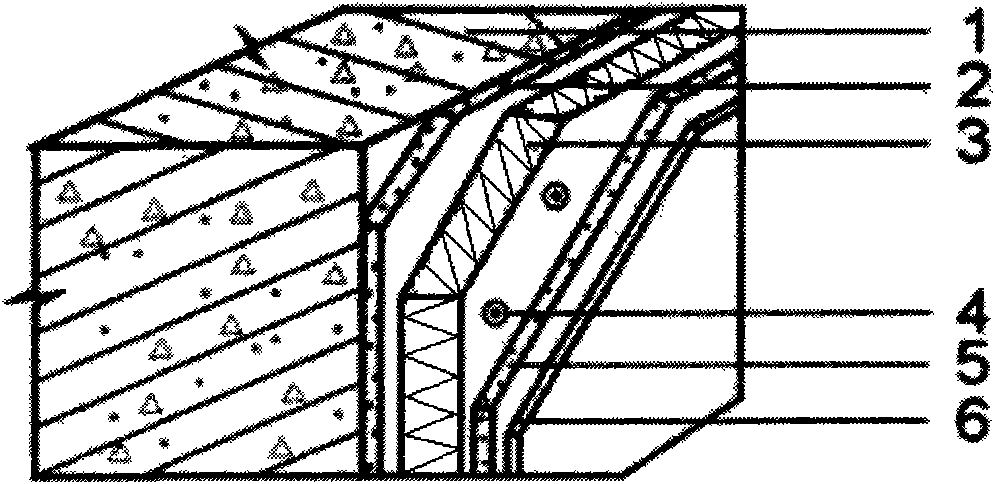

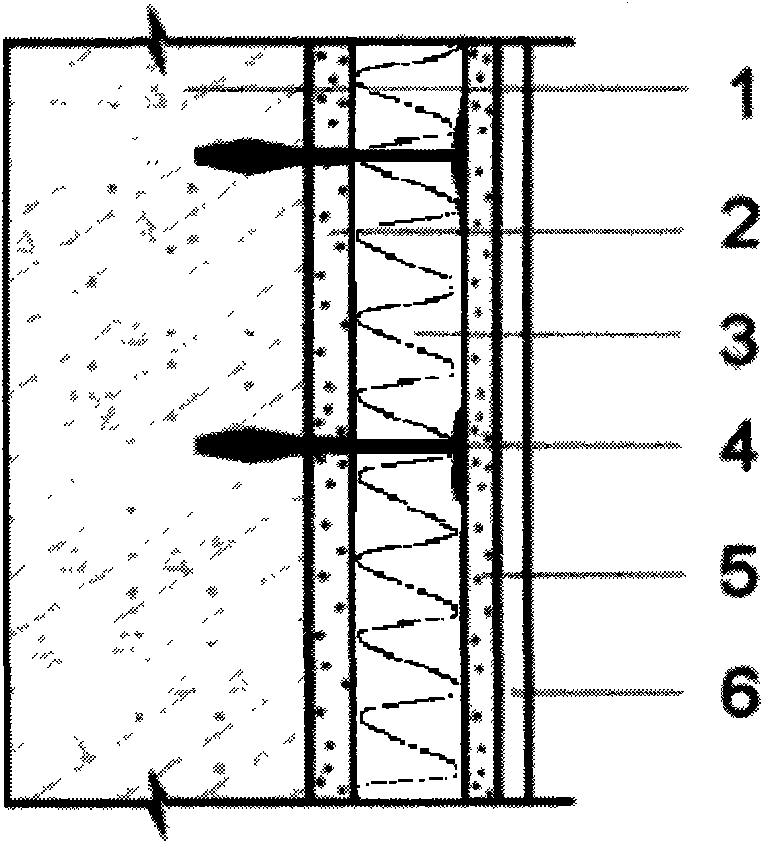

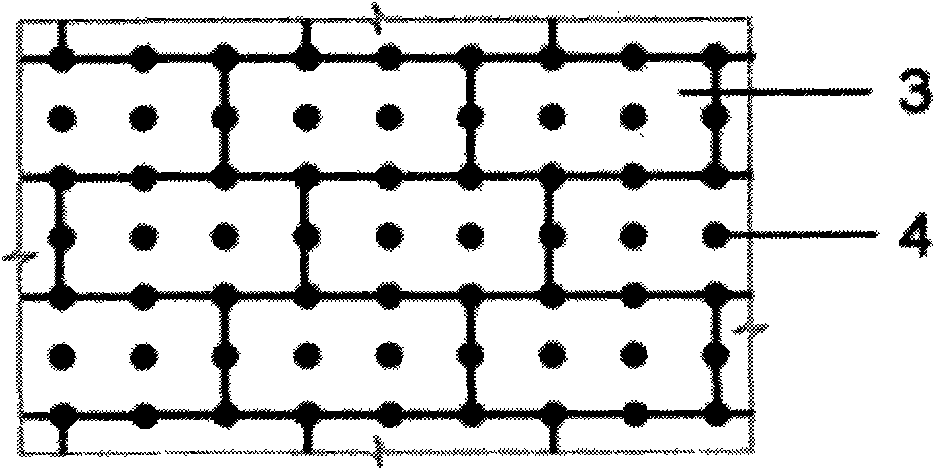

[0018] exist figure 1 Among them, the external thermal insulation wall of the present invention consists of base wall 1, leveling and bonding layer 2, grid reinforcement mineral wool board 3, plastic expansion anchor bolt 4, thin plastering protection surface layer 5 and decorative surface from inside to outside. Layer 6 composition. The base wall 1 can be a concrete wall, an aerated concrete block wall, a solid brick wall, a hollow brick wall or a lightweight cement sand block wall. The grid reinforcement mineral wool board 3 is composed of a mineral wool board and grid reinforcement ribs in the surface layer of the board surface. The mineral wool board is a glass wool board or a slag wool board; the grid reinforcement is a glass fiber mesh, a metal wire mesh Or chemical fiber mesh, according to the needs, the grid reinforcement can be set on both sides or on one side. The plastic expansion anchor bolt 4 can be a percussion anchor bolt or a screw anchor bolt, and the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com