Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film and preparation method thereof

An al2o3-ma-sic-c, refractory castable technology, applied in the field of refractory materials, can solve the problems of difficult on-site construction and operation, difficult to improve the service life of the tapping ditch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

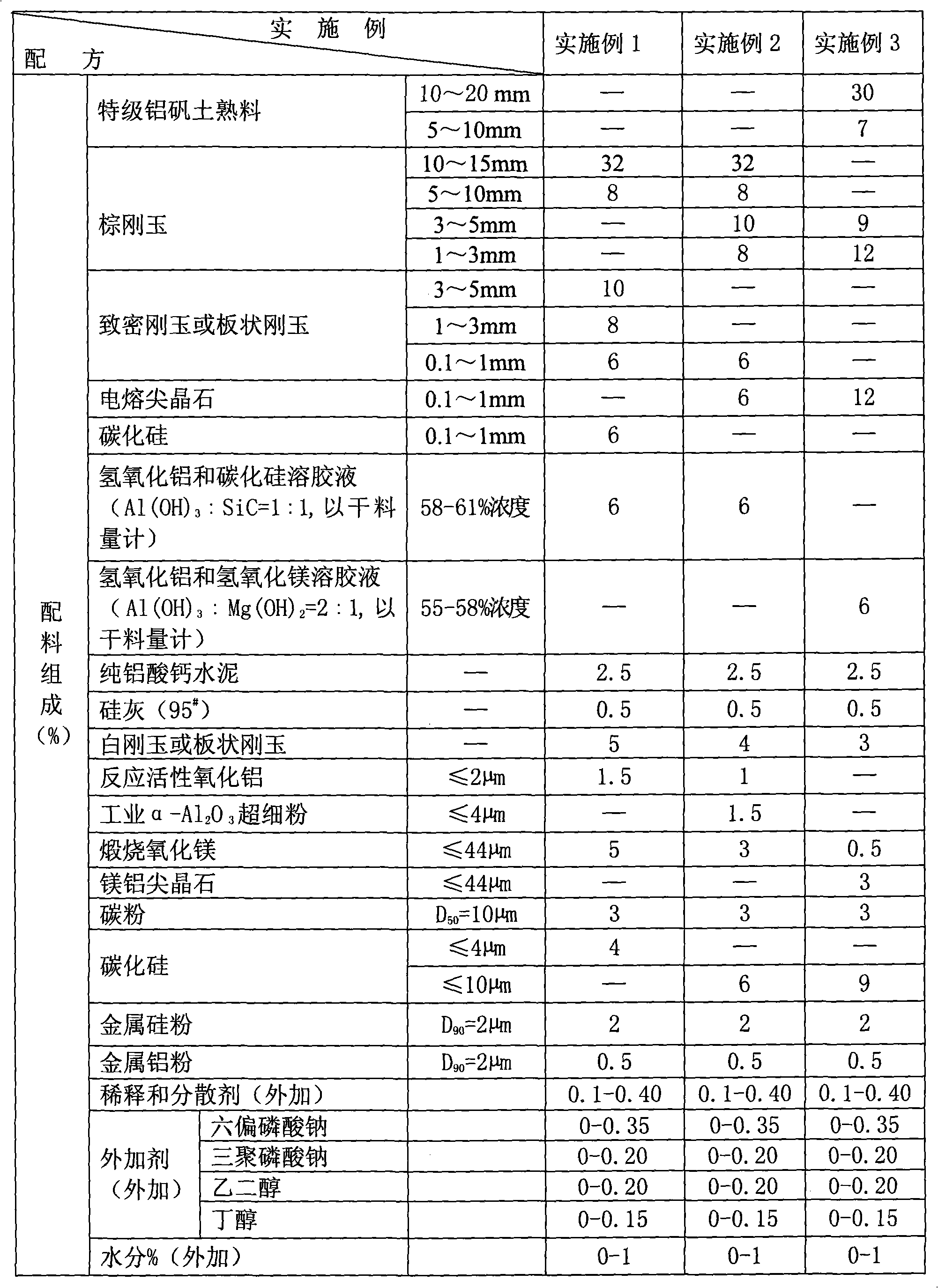

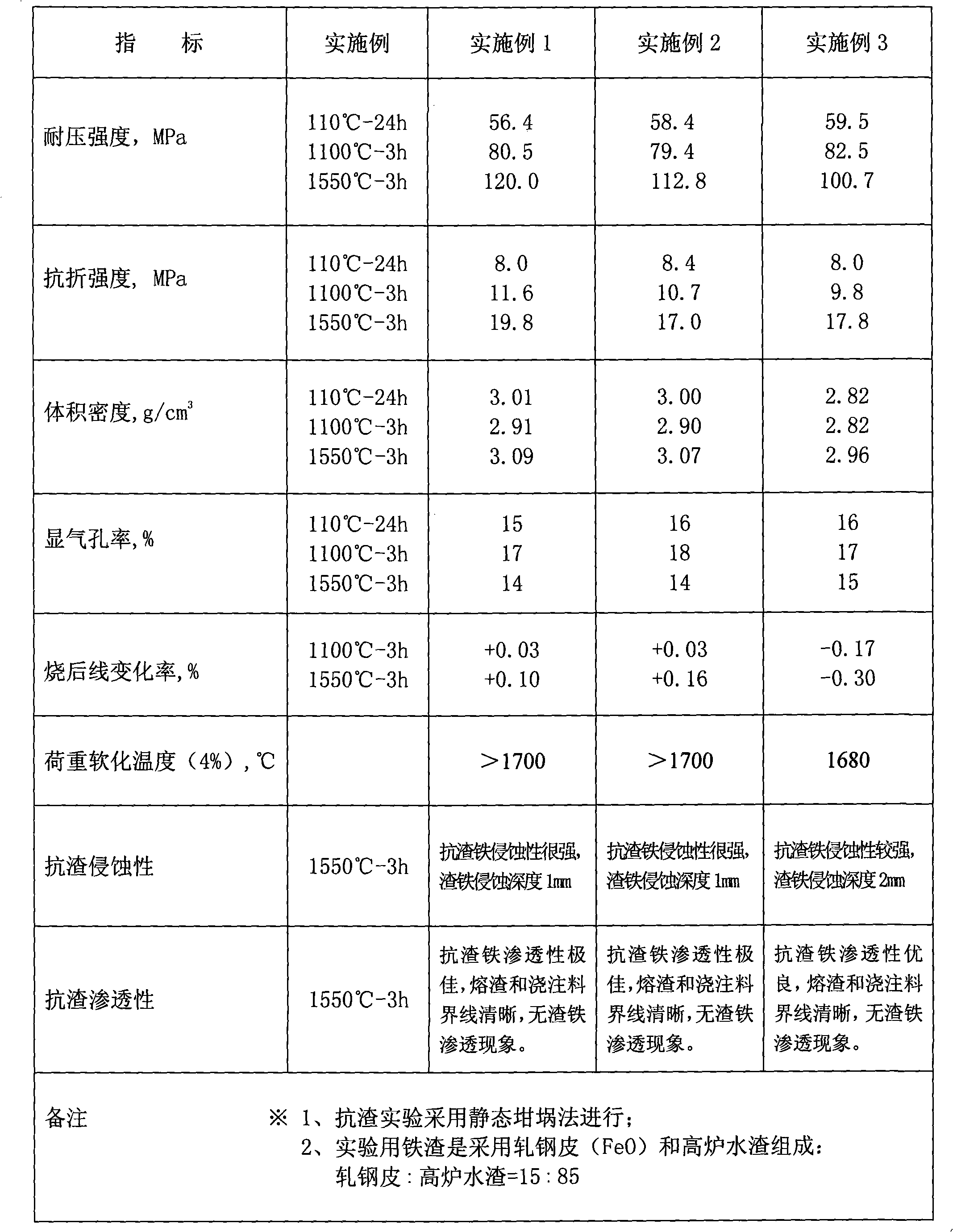

Embodiment 1

[0055] Embodiment 1 that the present invention is listed in table 1 is to use Al(OH) 3 Al and SiC Composite Sol Suspension Thin Film Encapsulated Carbon 2 o 3 -MA-SiC-C castable formula, the prepared mixture is added to the mixer, and then a certain concentration of carbon-Al(OH) 3 and SiC composite sol suspension are directly added to the mixture, and during the wet mixing process, the calcined MgO powder in the mixture and the mixed water undergo a hydration reaction at room temperature to generate Mg(OH) 2 Sol liquid, the two composite sol suspensions are strongly adsorbed on the surface of the carbon powder through the combination and adsorption of the sol, forming a full-coverage, crack-free, dense carbon coating, and the transition from sol to gel process, the formation of nano-Al 2 o 3 and MgO gel particles, in the heating process, through the in-situ synthesis reaction, the nanostructure matrix with nano-secondary spinel, aluminum oxide, silicon carbide and carbon ...

Embodiment 2

[0058] The present invention is listed in table 1 embodiment 2 is to use Al(OH) 3 Al and SiC Composite Sol Suspension Thin Film Encapsulated Carbon 2 o3 -MA-SiC-C castable formula, add the prepared mixture into the forced mixer, and then process a certain concentration of carbon-Al(OH) through high-speed impact stirring 3 and SiC composite sol suspension, directly added to the mixture, through the combination and adsorption of the sol, the composite sol is strongly adsorbed on the surface of the carbon powder, forming a full-coverage, crack-free, dense carbon coating layer. During the conversion of sol to gel, nano-Al 2 o 3 and MgO gel particles, in the heating process, through the in-situ synthesis reaction, a nano-structured matrix with nano-secondary spinel, aluminum oxide, silicon carbide, and carbon as the main components has been generated, and the Al of the present invention has been made. 2 o 3 -MA-SiC-C refractory castable.

[0059] The main feature of this embod...

Embodiment 3

[0061] The present invention is listed in the total reaction synthesis of the embodiment 3 of table 1 with nanometer Al 2 o 3 Combined with MgO ceramics and with Al(OH) 3 and Mg(OH) 2 Composite Sol Suspension Coated Carbon Al 2 o 3 -MA-SiC-C castable formula, the prepared mixture is added to the forced mixer, and then a certain concentration of carbon-Al(OH) 3 and Mg(OH) 2 Sol suspension, directly added to the mixture, through Al(OH) 3 and Mg(OH) 2 The combination and adsorption of the composite sol suspension makes the composite sol strongly adsorb on the surface of the carbon powder, forming a full-coverage, crack-free, and dense carbon coating. Compared with Example 2, this method simplifies the production process and can be added to the mixture to obtain a larger amount of nano-secondary spinel. During the conversion of sol to gel, nano-Al 2 o 3 and MgO gel particles, in the heating process, through the in-situ synthesis reaction, a nano-structured matrix with nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com