Preparation method of three-dimensional flower-shaped nickel cobaltate nano-sheet mesoporous microspheres

A three-dimensional flower-shaped, nano-sheet technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of simple operation, good experimental reproducibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

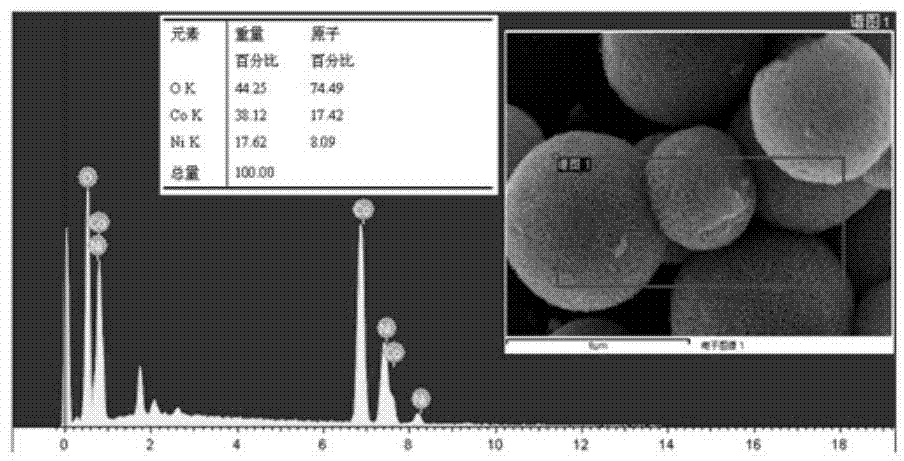

[0035] 1. Weigh 1.4540g nickel nitrate hexahydrate Ni(NO 3 ) 2 ·6H 2 O (0.005mol) and 2.9100g cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.010mol) was dissolved in 5mL of deionized water, ultrasonicated for 5min to prepare a mixed metal salt solution, then 75mL of isopropanol was added thereto, and magnetically stirred for 1h to obtain a mixed metal salt solution A, and 10mL of methanol was added to A to continue Stir for 0.5h to obtain mixed reaction solution B, wherein Ni 2+ and Co 2+ The total concentration is 0.167mol / L.

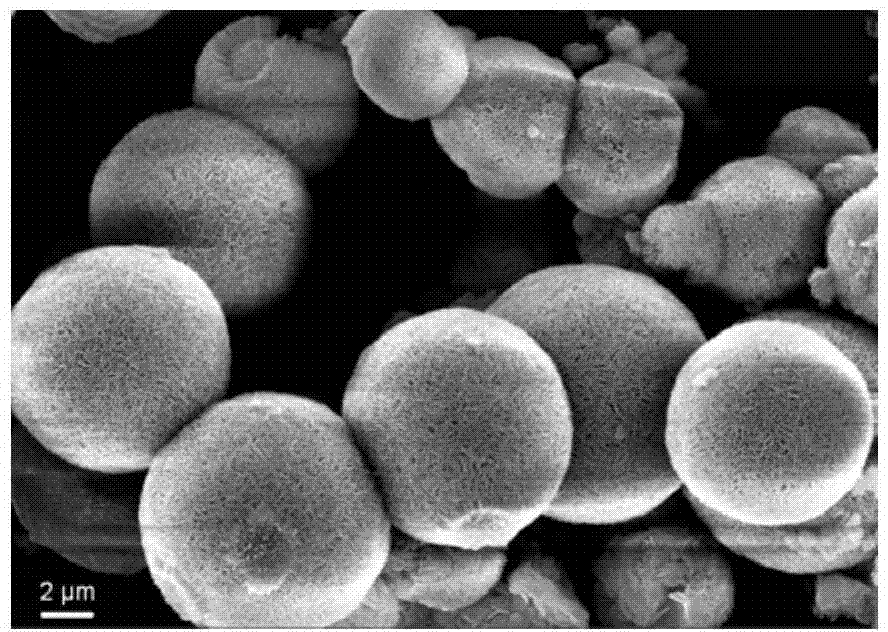

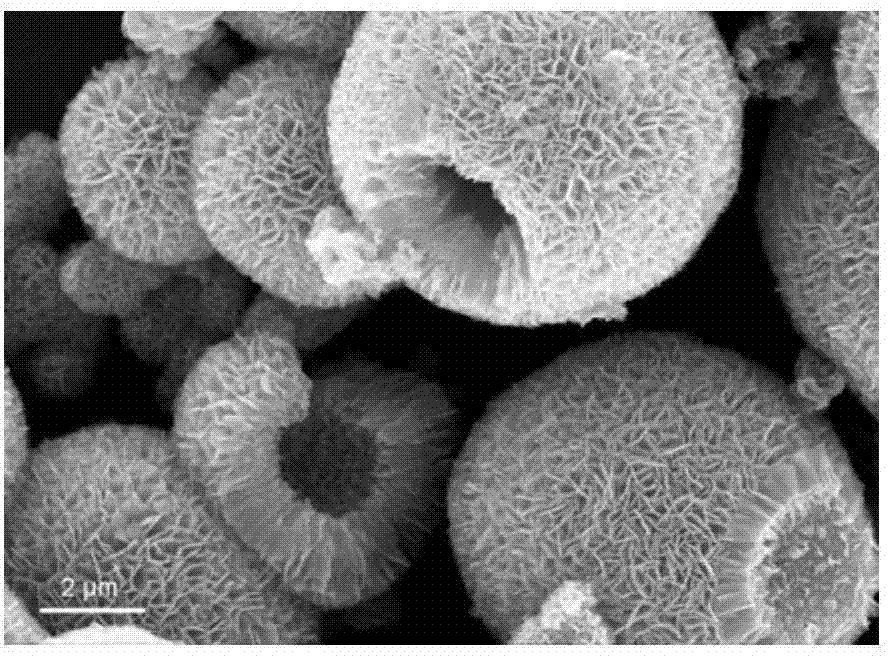

[0036] 2. Then transfer to a 100mL reactor, and conduct hydrothermal treatment at 120°C for 24h. After naturally cooling to room temperature, it was centrifuged, washed alternately with ethanol and deionized water for 3 times until the supernatant had a pH of 7, and dried in vacuum at 80°C for 24 hours to obtain a three-dimensional flower-like nanosheet microsphere precursor. Its SEM image is shown in figure 1 .

[0037] 3. The above precu...

Embodiment 2

[0040] Electrode materials prepared from three-dimensional flower-like nickel cobalt oxide nanosheet mesoporous microspheres and their electrochemical characterization

[0041] 1. Use the modified glassy carbon electrode as the working electrode. First, use 1.0 μm alumina polishing powder to rough polish the glassy carbon electrode on the polishing cloth for 3 minutes, and then use 0.05 μm alumina polishing powder to fine polish the glassy carbon electrode on buckskin for 3 minutes;

[0042] 2. After polishing, place the electrode in a nitric acid solution with a volume ratio of 1:1, anhydrous ethanol and deionized water for 3 minutes, and dry it at room temperature for use;

[0043] 3. Add 10 mg of the three-dimensional flower-shaped nickel cobaltate nanosheet mesoporous microsphere powder prepared in Example 1 into 0.9 mL of absolute ethanol and 0.1 mL of 0.5 wt % Nafion solution, and ultrasonically disperse evenly; Drop 1 μL of the suspension on the surface of the electrod...

Embodiment 3

[0049] 1. Weigh 1.4540g nickel nitrate hexahydrate Ni(NO 3 ) 2 ·6H 2 O (0.0050mol) and 2.9100g cobalt nitrate hexahydrate Co(NO 3 ) 2 ·6H 2 O (0.010mol) was dissolved in 5mL of deionized water, ultrasonicated for 5min to prepare a mixed metal salt solution, then 75mL of isopropanol was added thereto, and magnetically stirred for 1h to obtain a mixed metal salt solution A, and 10mL of methanol was added to A to continue Stir for 0.5h to obtain mixed reaction solution B, wherein Ni 2+ and Co 2+ The total concentration is 0.167mol / L.

[0050] 2. Then transfer to a 100mL reactor, and conduct hydrothermal treatment at 120°C for 12h. After naturally cooling to room temperature, it was centrifuged, washed alternately with ethanol and deionized water for 3 times until the supernatant had a pH of 7, and dried in vacuum at 80°C for 24 hours to obtain a three-dimensional flower-like nanosheet microsphere precursor.

[0051] 3. Calcinate the above precursor in an air atmosphere at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com