Sintered in-ga-zn-o-type oxide

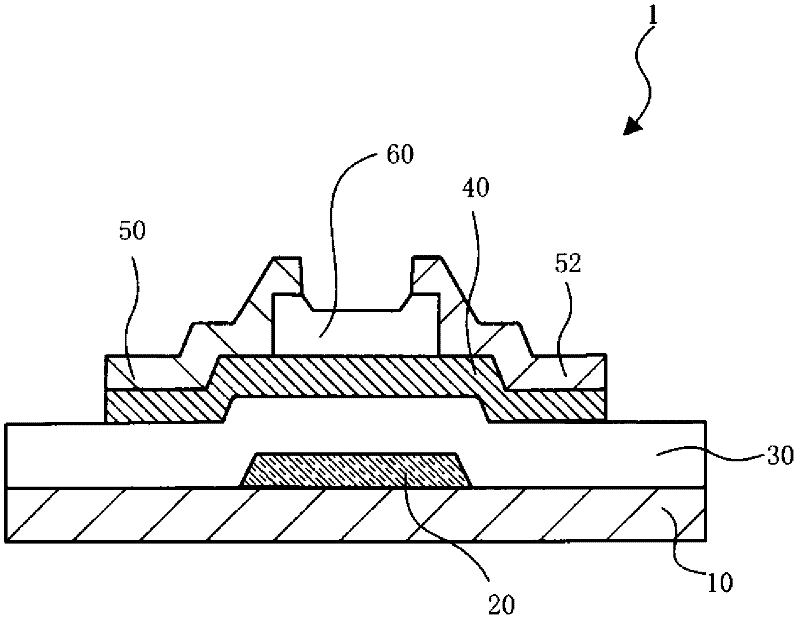

A technology of sintered body and oxide, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid state devices, etc., to achieve the effect of high relative density, high flexural strength and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

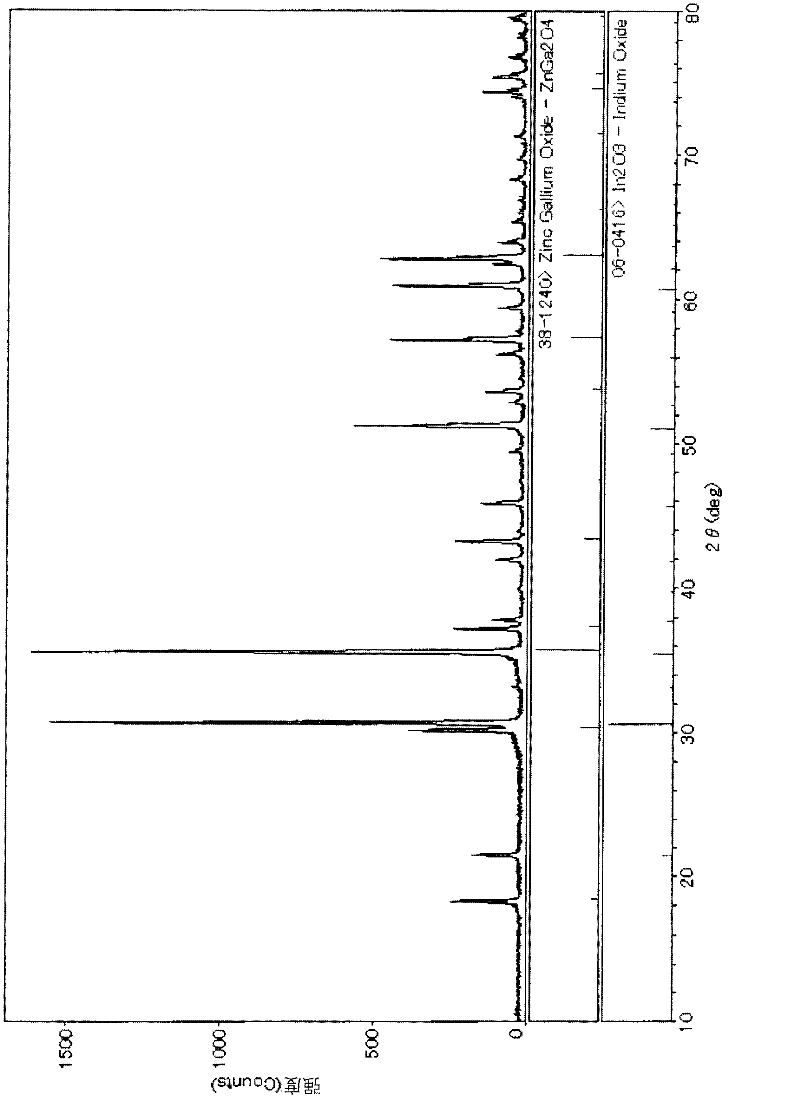

[0188] Example 1 [Production of oxide sintered body]

[0189] As raw material powder, In is used 2 O 3 (Specific surface area: 11m 2 / g, purity 99.99%), Ga 2 O 3 (Specific surface area: 11m 2 / g, purity 99.99%) and ZnO (specific surface area: 9m 2 / g, purity 99.99%) of each powder. The raw materials were mixed so as to have the atomic composition ratio shown in Table 1, and mixed with a super mixer for 4 minutes. The mixing is performed in the atmosphere at a rotation speed of 3000 rpm.

[0190] The obtained mixed powder was calcined in an electric furnace at 1000°C for about 5 hours in an air atmosphere. The obtained calcined powder was put into a pulverizer together with zirconia beads, and finely pulverized at a rotation speed of 300 rpm for 3 hours. As a result of fine pulverization, the particle size of the raw material powder was 0.55 μm in terms of the average particle size (D50).

[0191] To the finely pulverized raw material powder, water was added as a slurry (slurry) ha...

Embodiment 2

[0231] Example 2, Comparative Example 1, 2

[0232] As shown in Table 1, except for changing the composition and sintering conditions, a target and a TFT were produced in the same manner as in Example 1, and evaluated. The results are shown in Table 1.

Embodiment 3

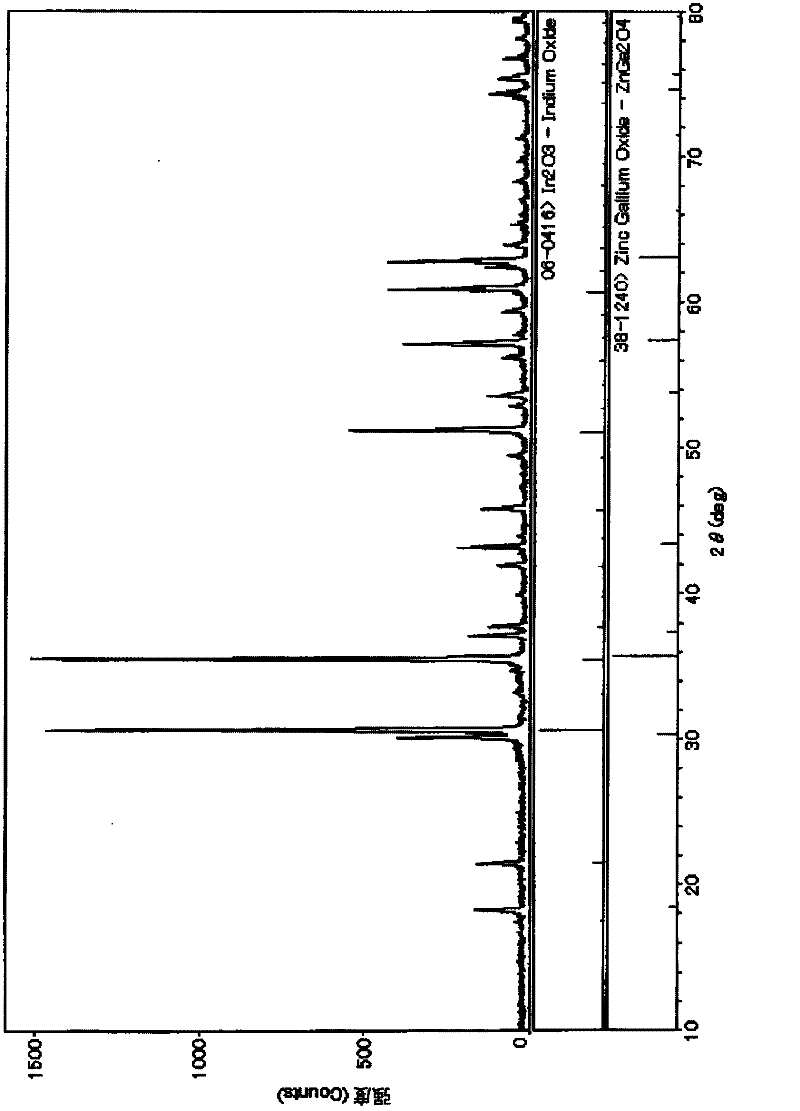

[0234] (A) Production of oxide sintered body

[0235] Mixing specific surface area 15m 2 / g, In with a purity of 99.99% 2 O 3 Powder, specific surface area 14m 2 / g, Ga with a purity of 99.99% 2 O 3 Powder, and specific surface area 4m 2 / g, ZnO powder with a purity of 99.99%, the particle size of each raw material powder was adjusted to 1 μm or less, and was mixed and pulverized with a ball mill. Take out the prepared slurry and use the slurry supply speed of 140ml / min, hot air temperature of 140℃, and hot air volume of 8Nm 3 Under the condition of / min, the spray dryer was used for rapid drying and granulation. The pellets are pressurized at 3ton / cm by cold isostatic pressing 2 Under the pressure of, the molded body is obtained.

[0236] Then, the compact is sintered. The temperature rise during sintering is performed at a rate of 0.5°C / min in the atmosphere until 600°C, and then at a rate of 1°C / min while introducing oxygen at a flow rate of 10L / min until 600~800°C Speed up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com