Ferrite/metal oxide material and preparation method and application thereof

A ferrite and oxide technology, applied in the application of photo-like Fenton reaction catalytic degradation of organic pollutants, the field of ferrite/metal oxide materials and their preparation, can solve the problem of slow reaction, difficult mass production, etc. problem, to achieve the effect of controllable composition, good stability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

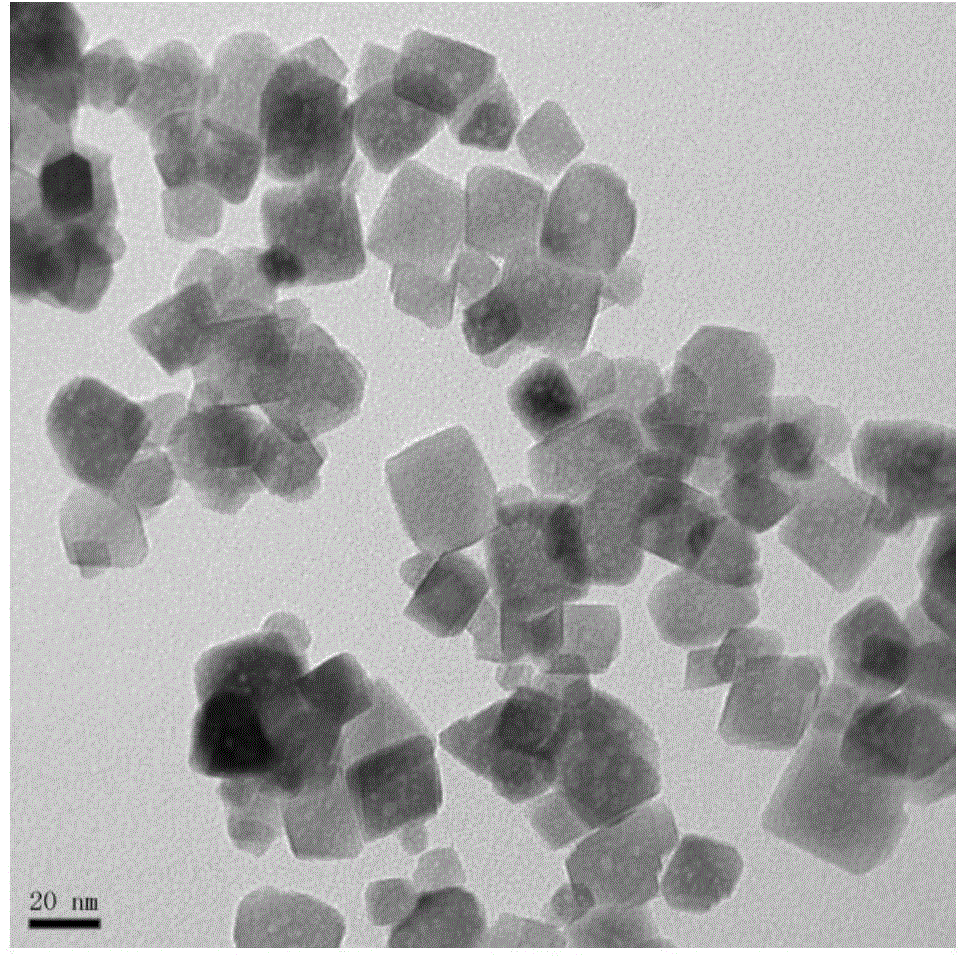

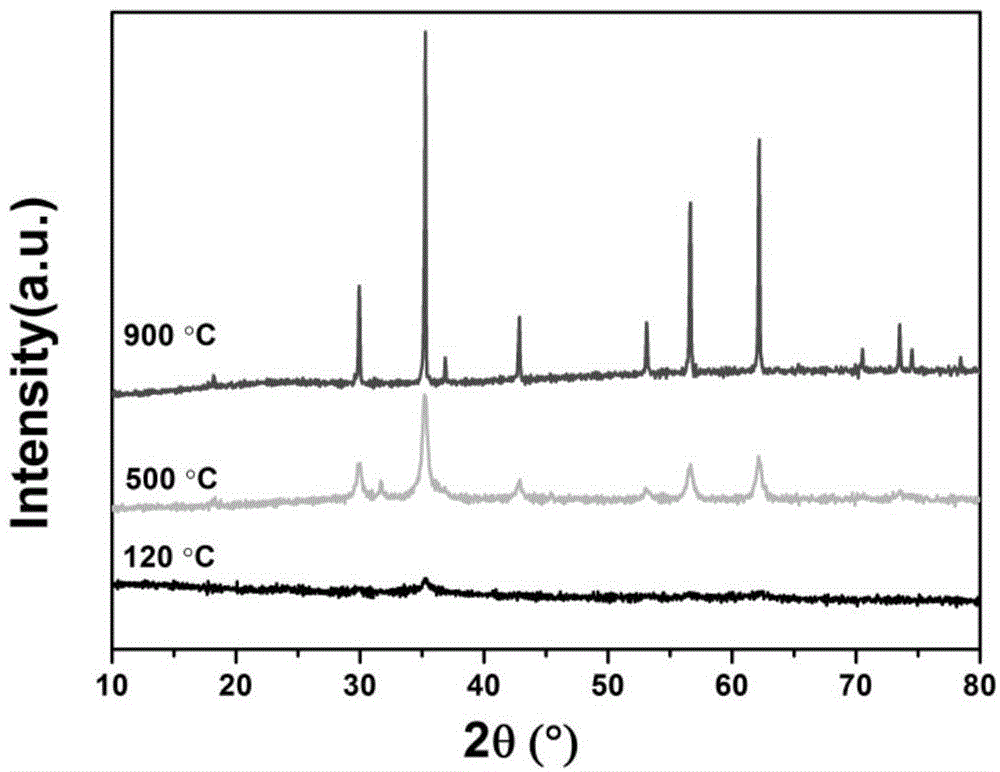

[0028] Take 0.547g of zinc acetylacetonate and 1.466g of iron acetylacetonate into a 1L beaker, add 60mL of ethylene glycol monoethyl ether, stir and dissolve in a 50°C water bath. Then 30 mL of 30% (v / v) hydrogen peroxide was added, and the reaction was stirred for 1 h. After the sol was obtained, the sol was transferred to an oven at 120° C. for 24 h to dry. Calcined at 500°C for 4 hours to obtain ZnFe 2 o 4 -Composite materials of ZnO.

Embodiment 2

[0030] Take 0.547g of zinc acetylacetonate and 1.466g of iron acetylacetonate into a 1L beaker, add 60mL of ethylene glycol monoethyl ether, stir and dissolve in a 50°C water bath. Then 30 mL of 30% (v / v) hydrogen peroxide was added, and the reaction was stirred for 1 h. After the sol was obtained, the sol was transferred to an oven at 120° C. for 24 h to dry. Calcined at 900°C for 4 hours to obtain ZnFe 2 o 4 nano ferrite.

Embodiment 3

[0032] Take 0.547g of zinc acetylacetonate and 1.466g of iron acetylacetonate and place them in a 1L beaker, add 30mL of ethylene glycol monoethyl ether, stir and dissolve in a 50°C water bath. Then 30 mL of 30% (v / v) hydrogen peroxide was added, and the reaction was stirred for 1 h. After the sol was obtained, the sol was transferred to an oven at 120° C. for 24 h to dry. Calcined at 500°C for 4 hours to obtain ZnFe 2 o 4 -Composite materials of ZnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com