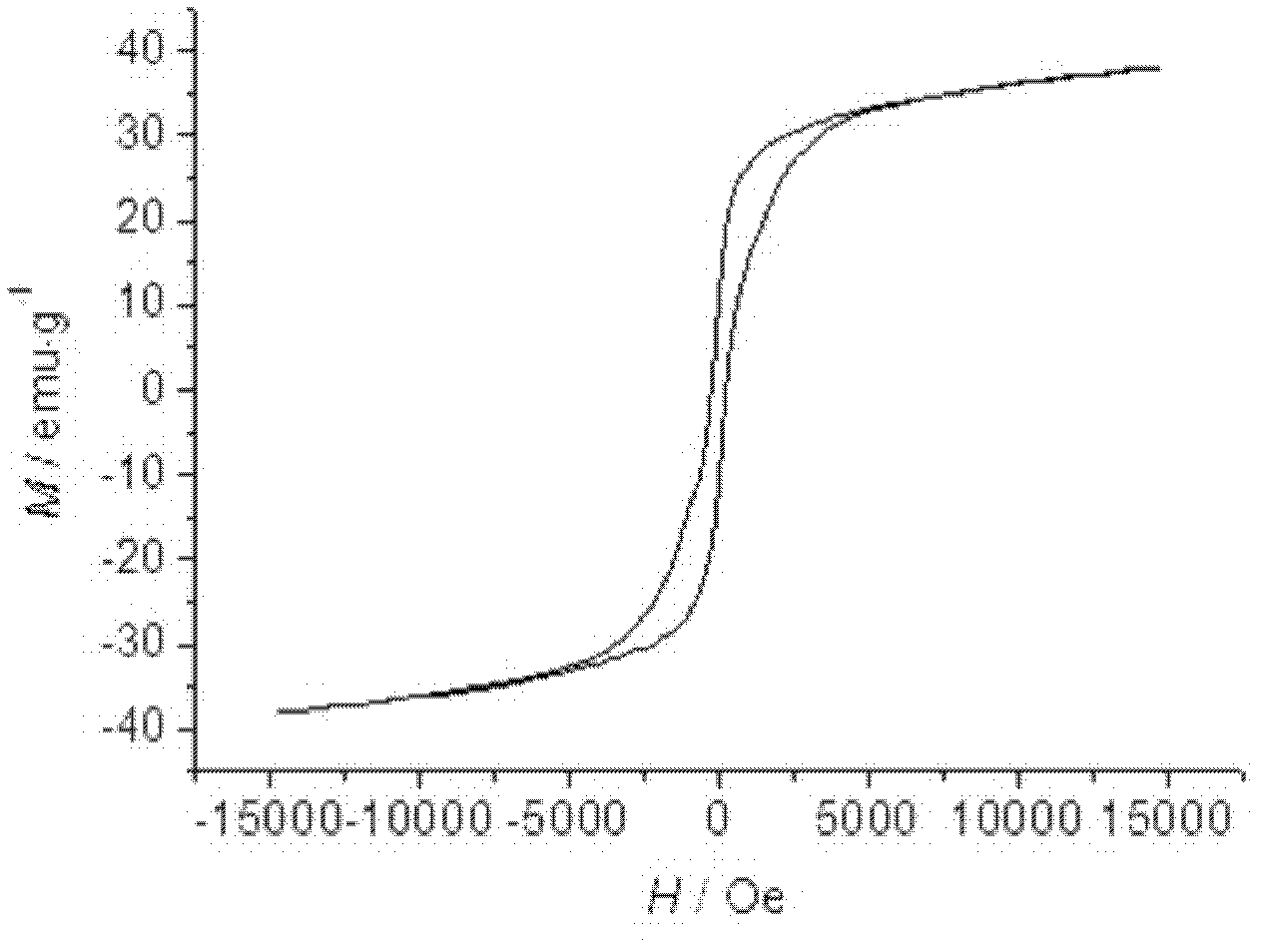

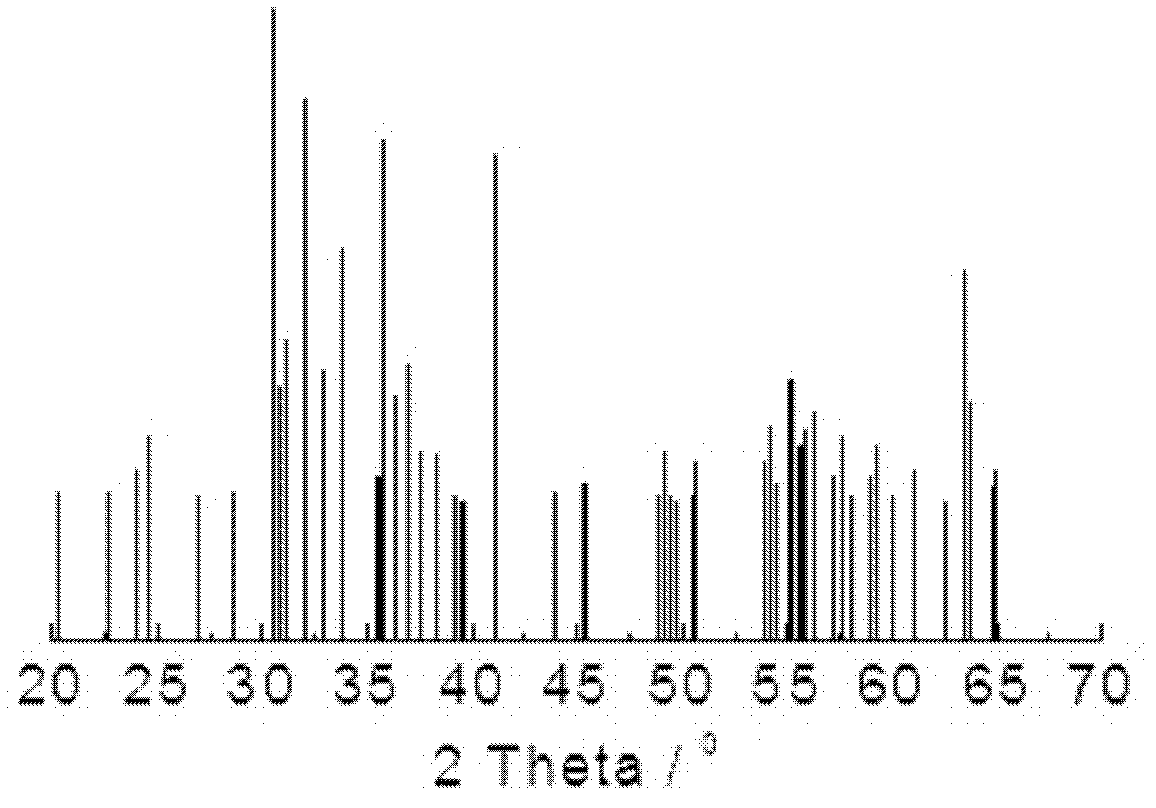

Hexagonal crystal system Y-type ferrite electromagnetic material and preparation method thereof

A technology of electromagnetic materials and hexagonal crystal system, which is applied in the field of hexagonal crystal Y-type ferrite electromagnetic materials and its preparation, can solve the problems of uneven dispersion, widening of powder particle size distribution, and many influencing factors, and achieve low synthesis temperature , Narrow particle size distribution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) According to Ba / Fe=2:12 (molar ratio), Ba / Co=2:2 (molar ratio), Ba / (Co+Zn)=2:2 (molar ratio), weigh a certain amount of Barium Carbonate BaCO 3 , Fe2O3 2 o 3 , cobalt tetroxide Co 3 o 4 , mixed and ground finely (300rpm / min × 60-360min ball milling in an agate jar of a ball mill, using distilled water or absolute ethanol or acetone as a grinding aid, the mass ratio of the ball to material is 3:1, the same below), to obtain the reactant.

[0044] (2) Take by weighing sodium chloride and potassium chloride mixed salt (sodium chloride and potassium chloride molar ratio 1: 1) by chlorate quality / reactant quality=1: 1 (mass ratio), mix and grind Evenly, the reaction medium was obtained.

[0045] (3) Mix and grind the reactant and the reaction medium until uniform, and dry at 105° C. to obtain the precursor.

[0046] (4) Put the precursor in a corundum crucible with a cover and put it into a muffle furnace for calcination at 900°C, keep it warm for 3 hours, and cool...

Embodiment 2

[0050] A hexagonal Y-type ferrite electromagnetic material and a preparation method thereof, comprising the following steps:

[0051] (1) According to Ba / Fe=2:12 (molar ratio), Ba / Co=2:0 (molar ratio), Ba / (Co+Zn)=2:2 (molar ratio), weigh a certain amount of Barium Carbonate BaCO 3 , Fe2O3 2 o 3 , cobalt tetroxide Co 3 o 4 , zinc oxide ZnO, mixed and ground finely (300rpm / min×60~360min ball mill in agate tank of ball mill, with distilled water or absolute ethanol or acetone as grinding aid, the mass ratio of ball to material is 3:1, the same below), get reactants.

[0052] (2) Take by weighing sodium chloride and potassium chloride mixed salt (sodium chloride and potassium chloride molar ratio 1: 1) by chlorate quality / reactant quality=1: 3 (mass ratio), mix and grind Evenly, the reaction medium was obtained.

[0053] (3) Mix and grind the reactant and the reaction medium until uniform, and dry at 105° C. to obtain the precursor.

[0054] (4) Put the precursor in a coru...

Embodiment 3

[0058] A hexagonal Y-type ferrite electromagnetic material and a preparation method thereof, comprising the following steps:

[0059] (1) According to Ba / Fe=2:12 (molar ratio), Ba / Co=2:0.8 (molar ratio), Ba / (Co+Zn)=2:2 (molar ratio), weigh a certain amount of Barium Carbonate BaCO 3 , Fe2O3 2 o 3 , cobalt tetroxide Co 3 o 4 , zinc oxide ZnO, mixed and ground finely (300rpm / min×60~360min ball mill in agate tank of ball mill, with distilled water or absolute ethanol or acetone as grinding aid, the mass ratio of ball to material is 3:1, the same below), get reactants.

[0060] (2) Take by weighing sodium chloride and potassium chloride mixed salt (sodium chloride and potassium chloride molar ratio 1: 1) by chlorate quality / reactant quality=1: 2 (mass ratio), mix and grind Evenly, the reaction medium was obtained.

[0061] (3) Mix and grind the reactant and the reaction medium until uniform, and dry at 105° C. to obtain the precursor.

[0062] (4) Put the precursor in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com