NiZn series ferrite material and preparing method thereof

A ferrite material and powder technology, which is applied in the field of ferrite material preparation, can solve the problems such as the inability to meet the miniaturization of electronic equipment, the reduction of the magnetic permeability of materials, the inability to meet the needs of high current and high-density installation applications, and the like. Achieve miniaturization, increase current carrying capacity, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

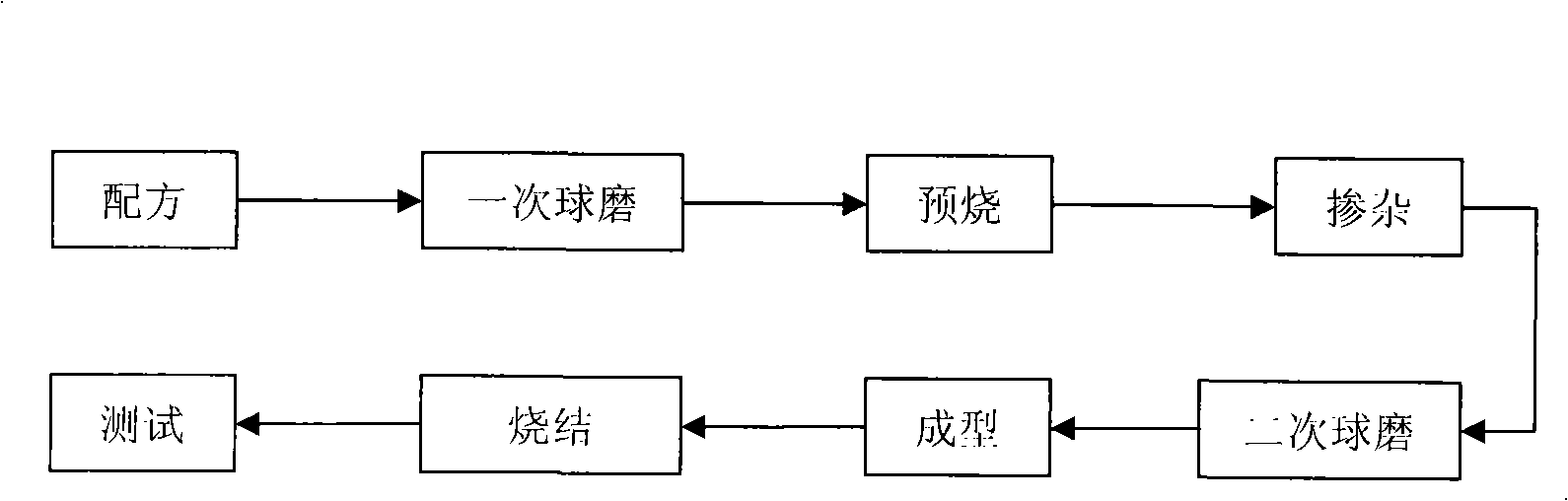

[0027] Aiming at the current domestic technical blank and demand for high-Bs and high-Tc NiZn-based ferrite materials, the invention provides a preparation technology for high-Bs and high-Tc NiZn-based ferrite materials. First, by optimizing high-purity Fe 2 o 3 , ZnO, CuO and NiO as raw materials, formulate the optimal formula range; secondly, deeply analyze the super exchange effect existing in NiZn ferrite materials, and study the additives CaO, MoO 3 、 Bi 2 o 3 , Nb 2 o 5 , V 2 o 5 , SnO 2 and other additives on the NiZn-based material super exchange mechanism, formulate the optimal additive formula; then, select superhard steel balls to grind the powder to below 1 μm, and prepare high-activity powder; finally, in the above formula, additives and powder On the premise of optimizing the body preparation process, combined with a specific sintering system, high Bs and high Tc NiZn ferrite materials were prepared at low temperature.

[0028] The main component of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com