Casting manufacturing method of superconducting NbTi alloy

A manufacturing method and alloy technology, which are applied in the field of casting and manufacturing of superconducting NbTi alloys, can solve the problems of inhomogeneity of NbTi superconducting alloy ingots, unfavorable NbTi alloy superconducting materials, affecting the cold working plasticity of superconducting materials, and the like, and achieving less interstitial elements. , good plasticity, high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

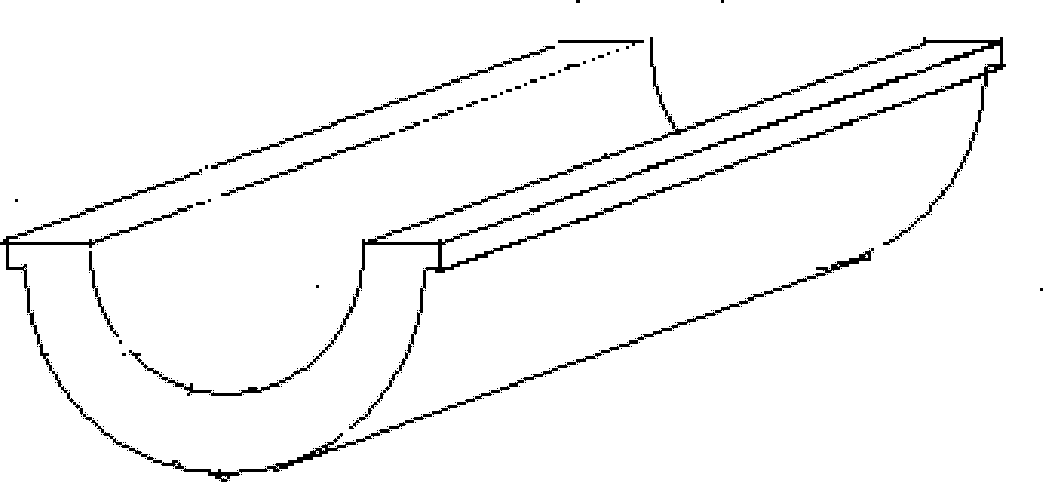

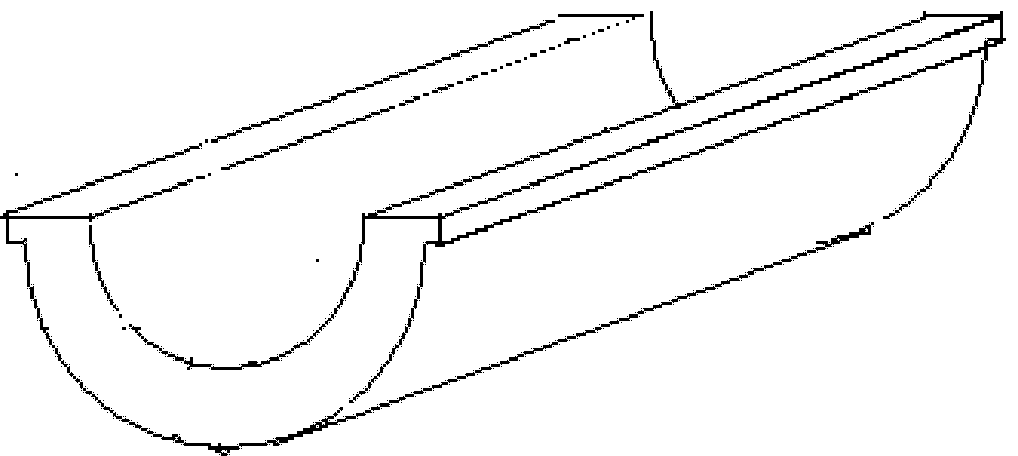

[0013] Purified niobium ingots are used, forged into rods, and then turned to remove the surface contamination layer. The removal amount should not be less than 1mm. Take niobium rods of Ф86×1450mm, and press the sponge titanium into such figure 1 For the 8 semi-cylindrical tiles shown, the weight of a single tile is 7.72Kg, and the niobium rods and tiles are assembled and welded under the protection of argon, and the welding is required to be firm and smooth. The electrode is smelted for the first time in a vacuum consumable electric arc furnace, and the smelting power is 250kW. The primary ingot of the niobium-titanium superconducting alloy obtained after the first smelting is made into a niobium-titanium consumable electrode with a diameter of 220mm. The melting power of more than 300kW is remelted in a vacuum consumable furnace, and the melt is fully stirred to further homogenize the niobium and titanium, and obtain the secondary ingot of niobium and titanium alloy.

Embodiment 2

[0015] Purified niobium ingots are used, forged into rods, and turned to remove the surface contamination layer. The removal amount should not be less than 1mm. Take Ф80×1450mm niobium rods and press the sponge titanium into such figure 1 In the 8 semi-cylindrical tiles shown, the weight of a single tile is 9.2Kg, and the niobium rods and tiles are assembled and welded under the protection of argon, and the welding is required to be firm and smooth. The electrode is smelted for the first time in a vacuum consumable electric arc furnace, and the smelting power is 230kW. The primary ingot of niobium-titanium superconducting alloy obtained after the first smelting is made into a niobium-titanium consumable electrode with a diameter of 220mm. The melting power of more than 300kW is remelted in a vacuum consumable furnace, and the melt is fully stirred to further homogenize the niobium and titanium, and obtain the secondary ingot of niobium and titanium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com