Patents

Literature

77results about How to "Reduce external pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

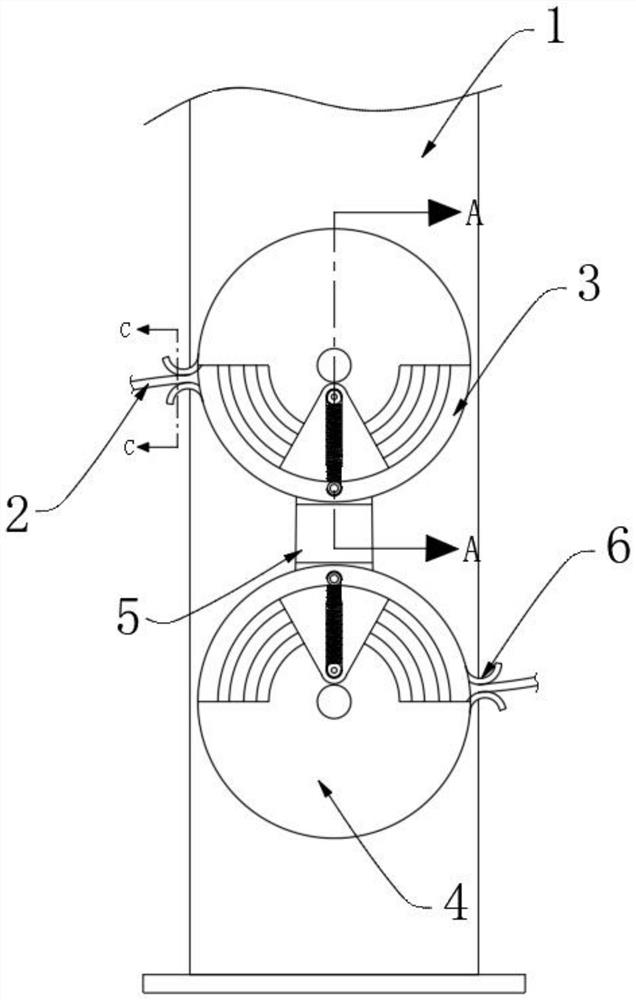

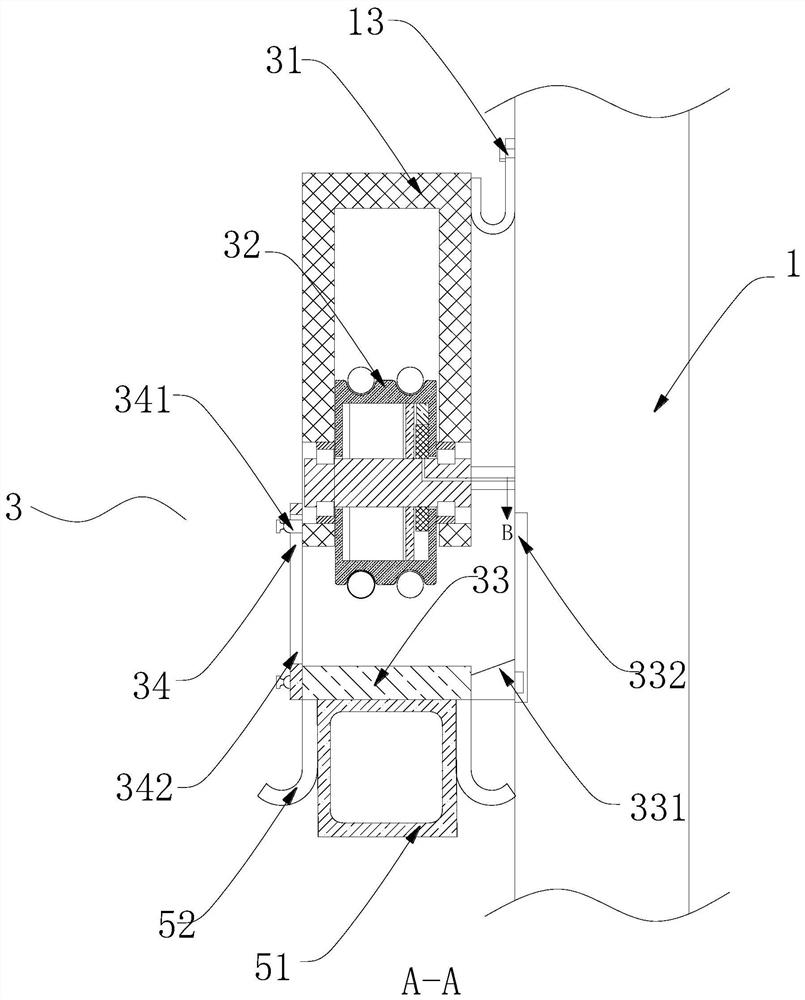

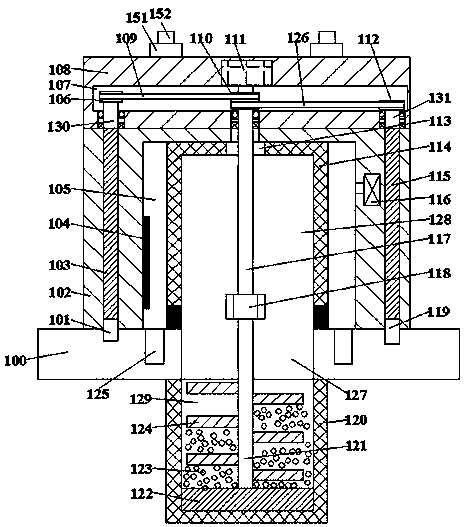

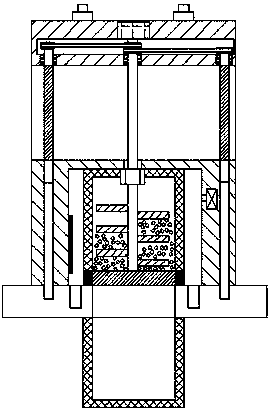

Modular animal digestive tract in-vitro simulation system and human intestinal tract simulation method thereof

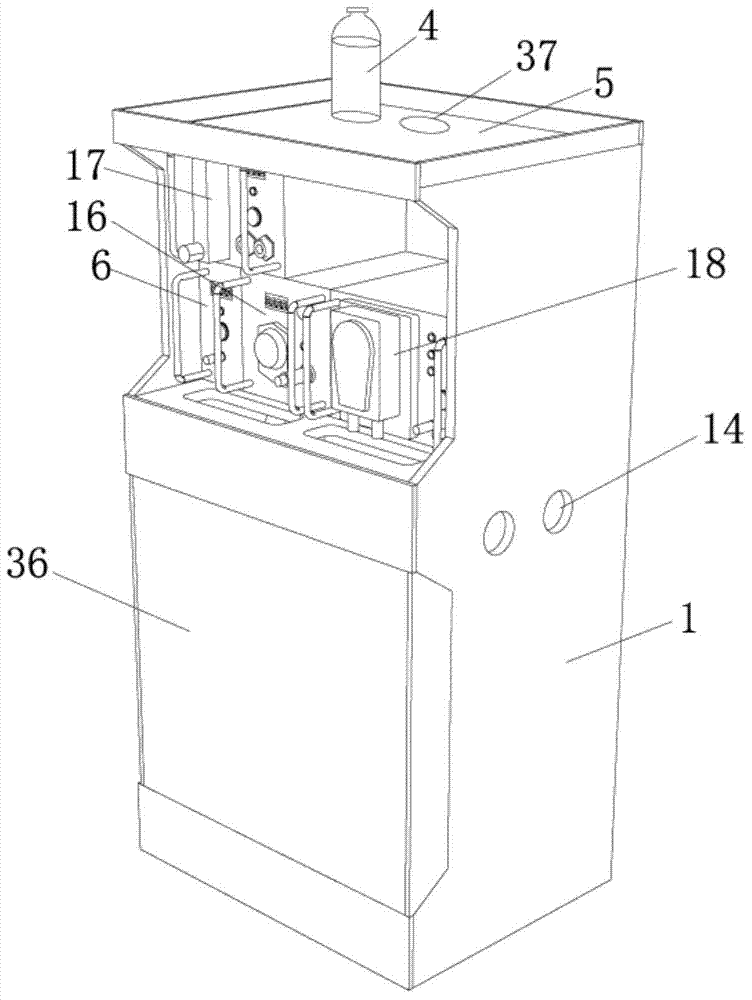

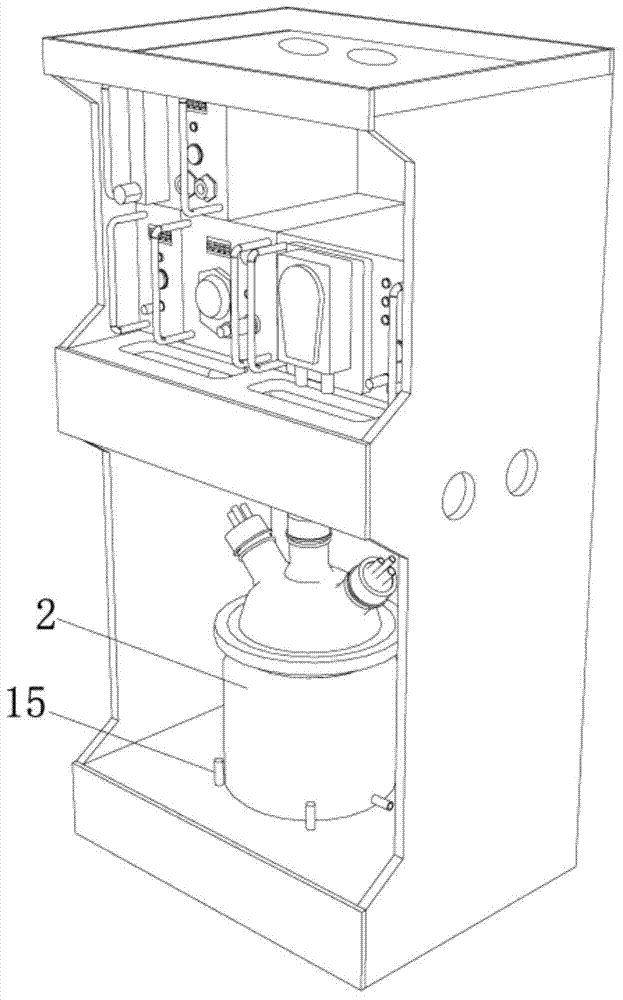

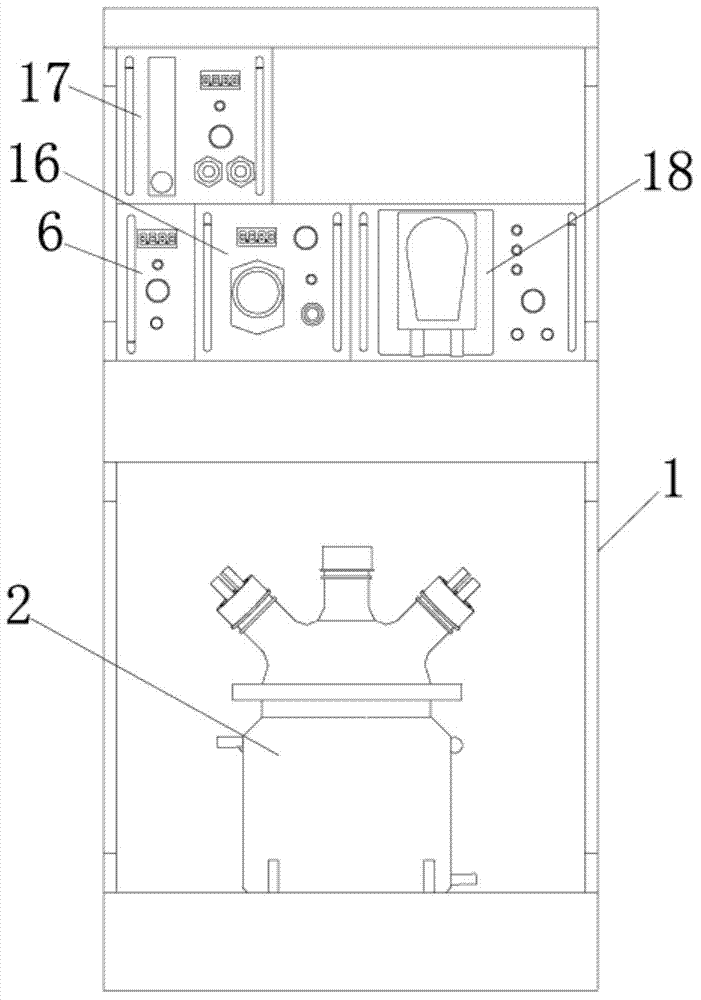

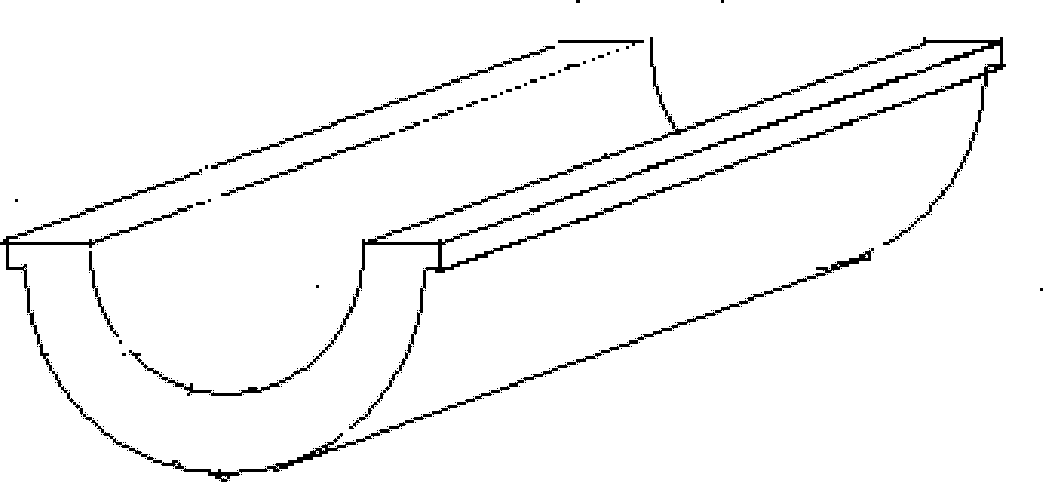

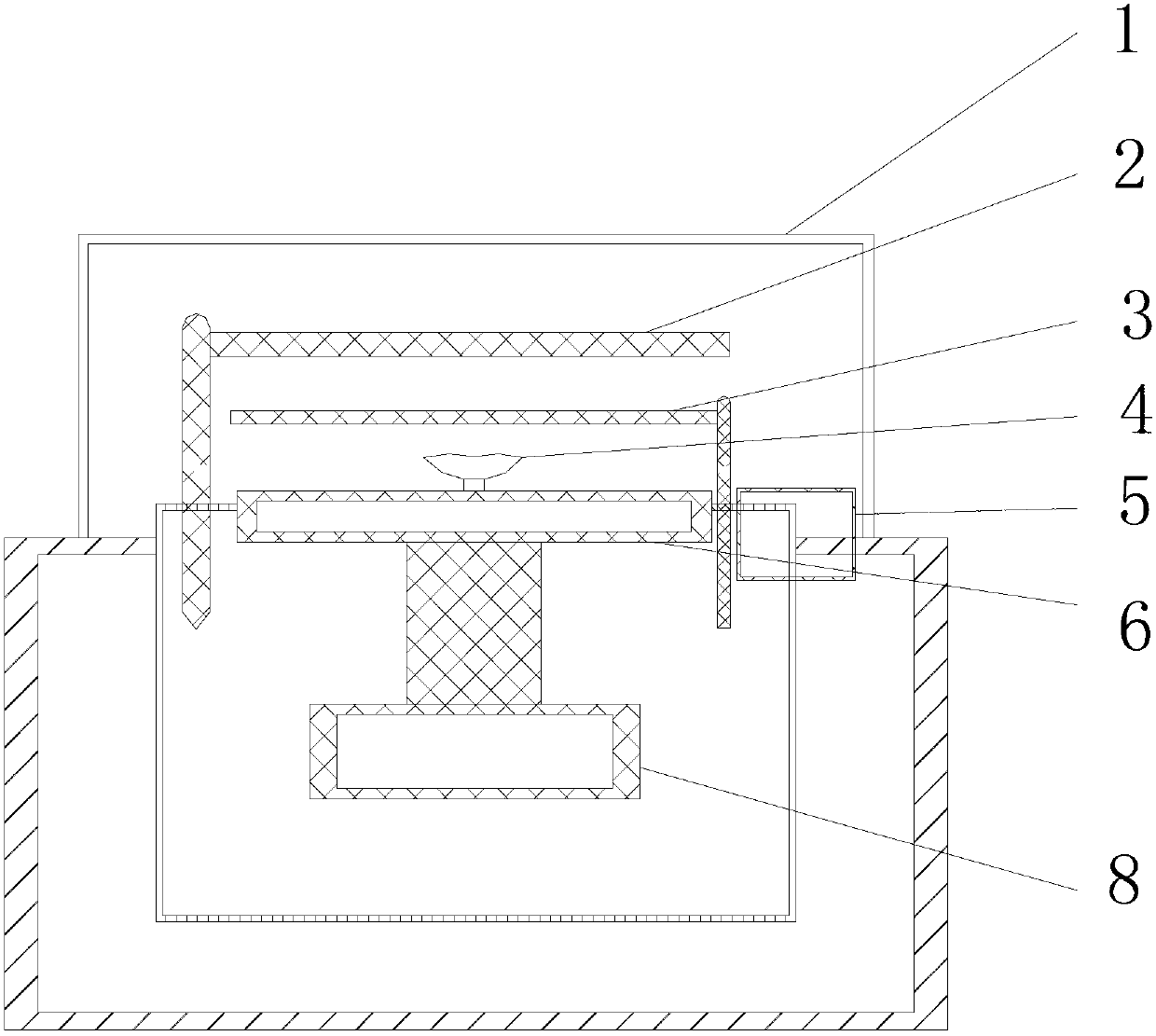

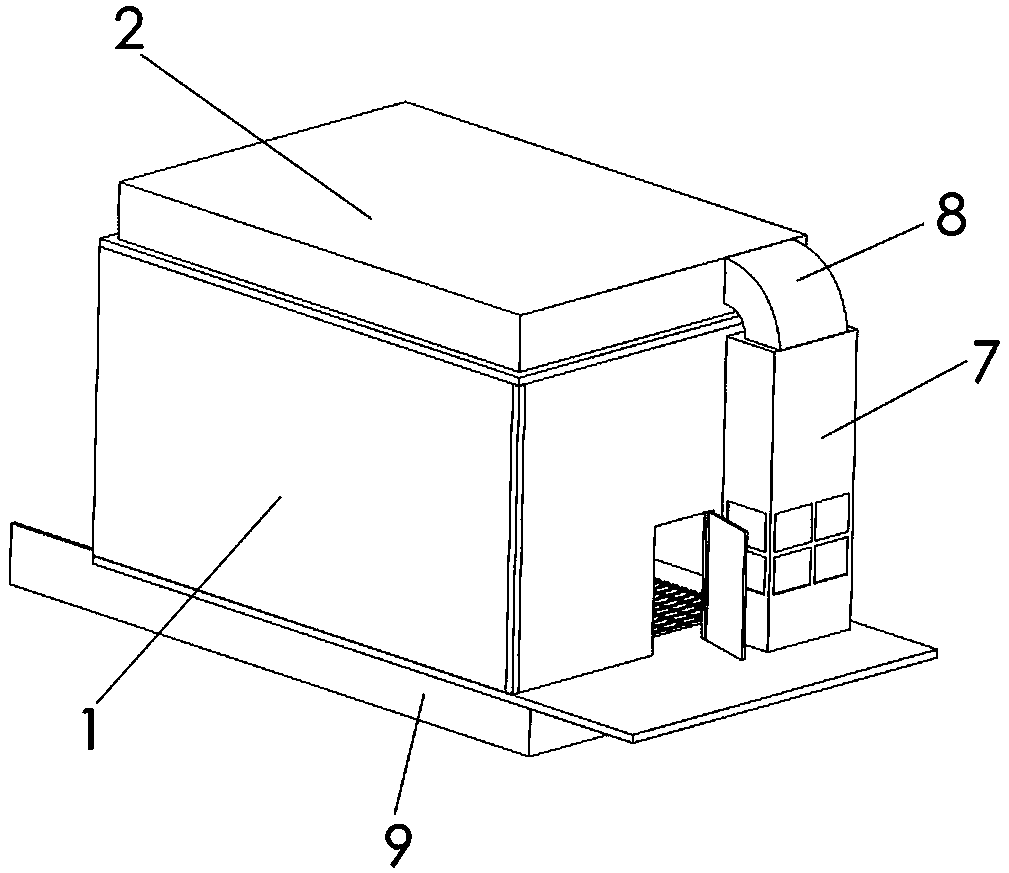

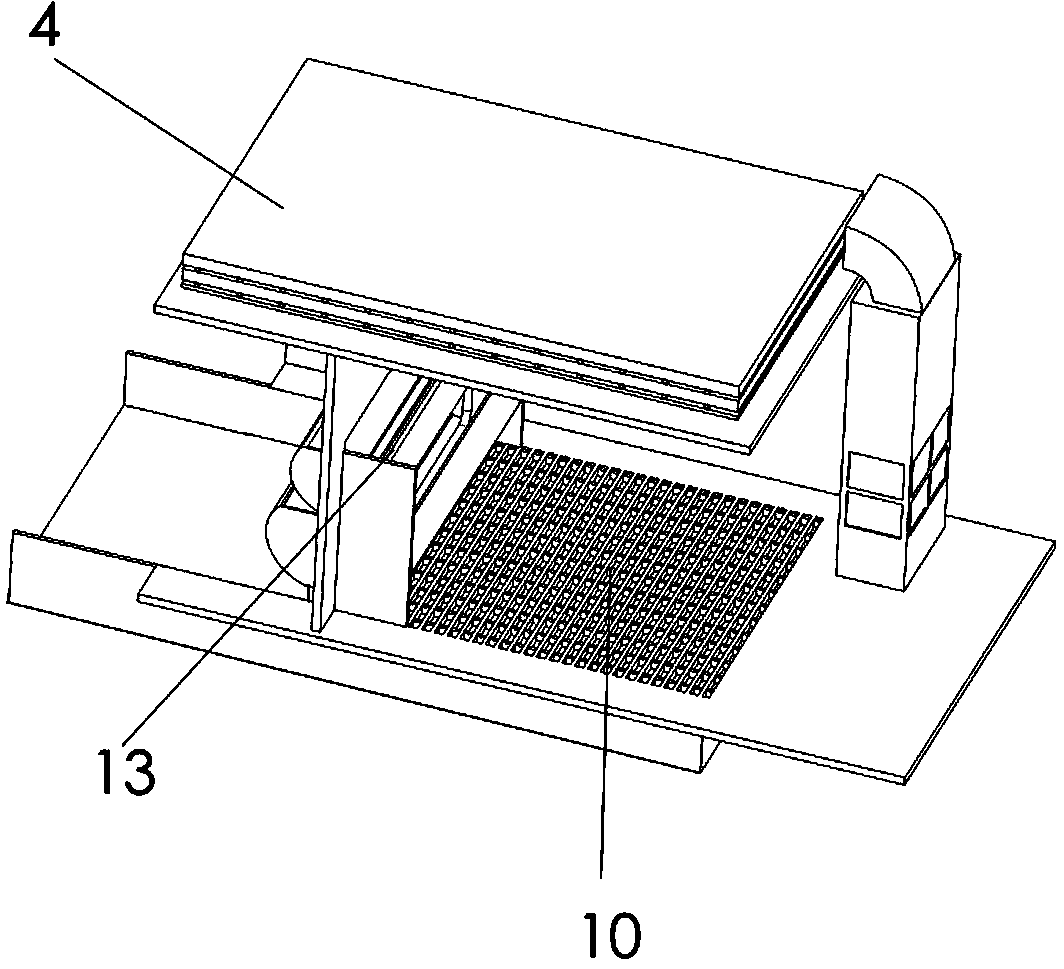

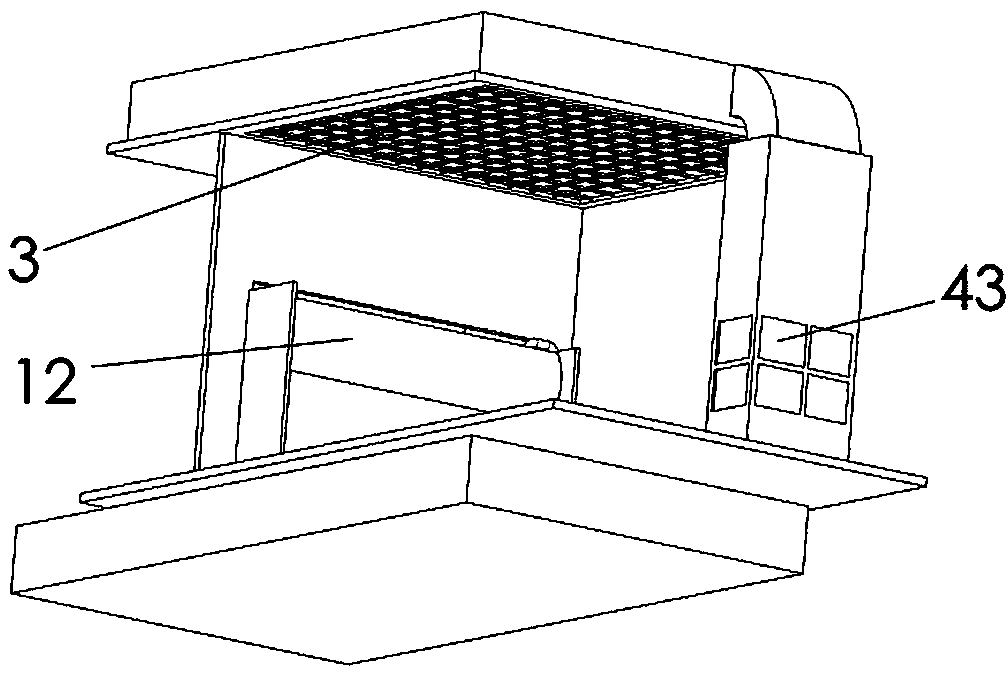

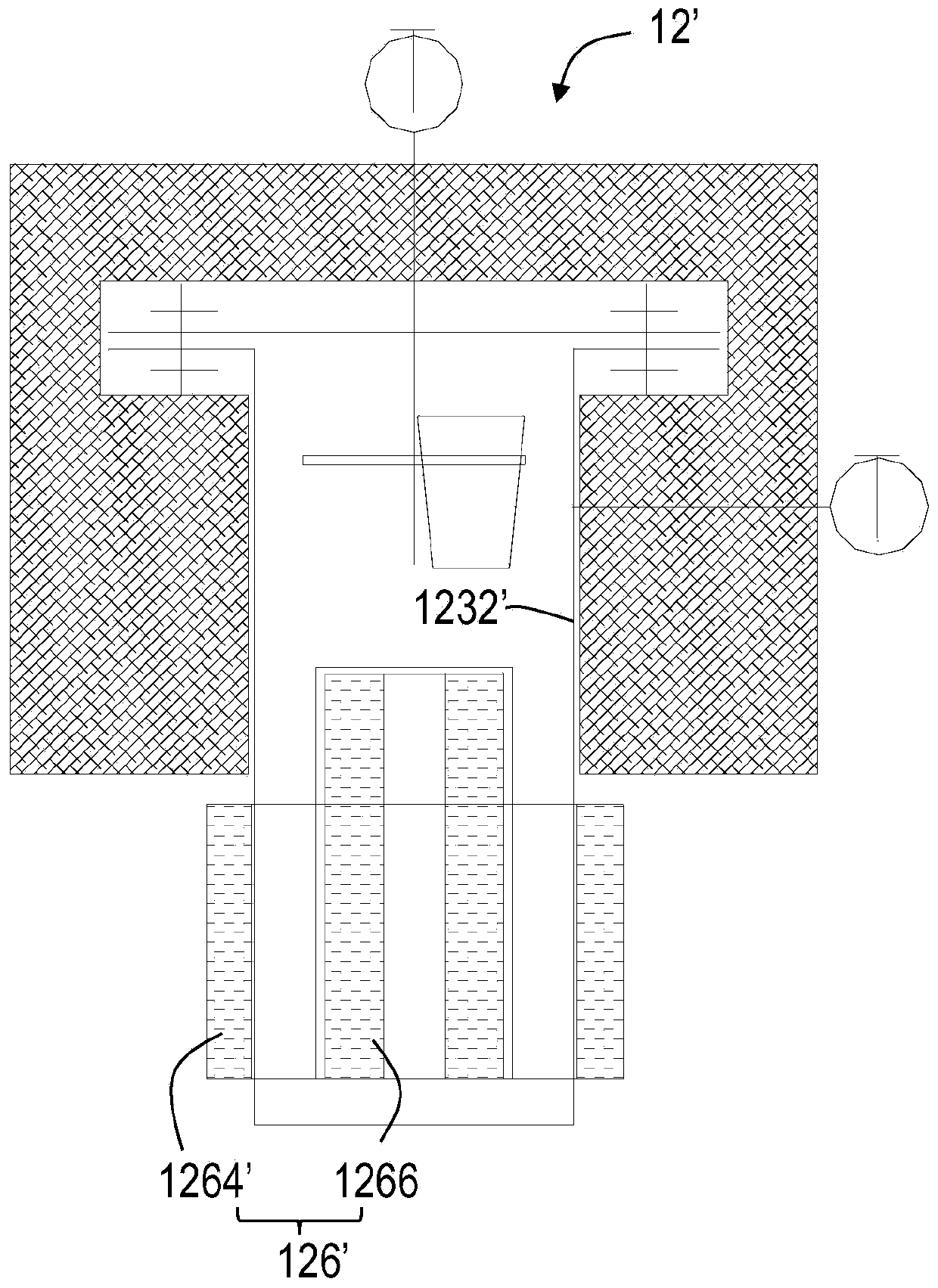

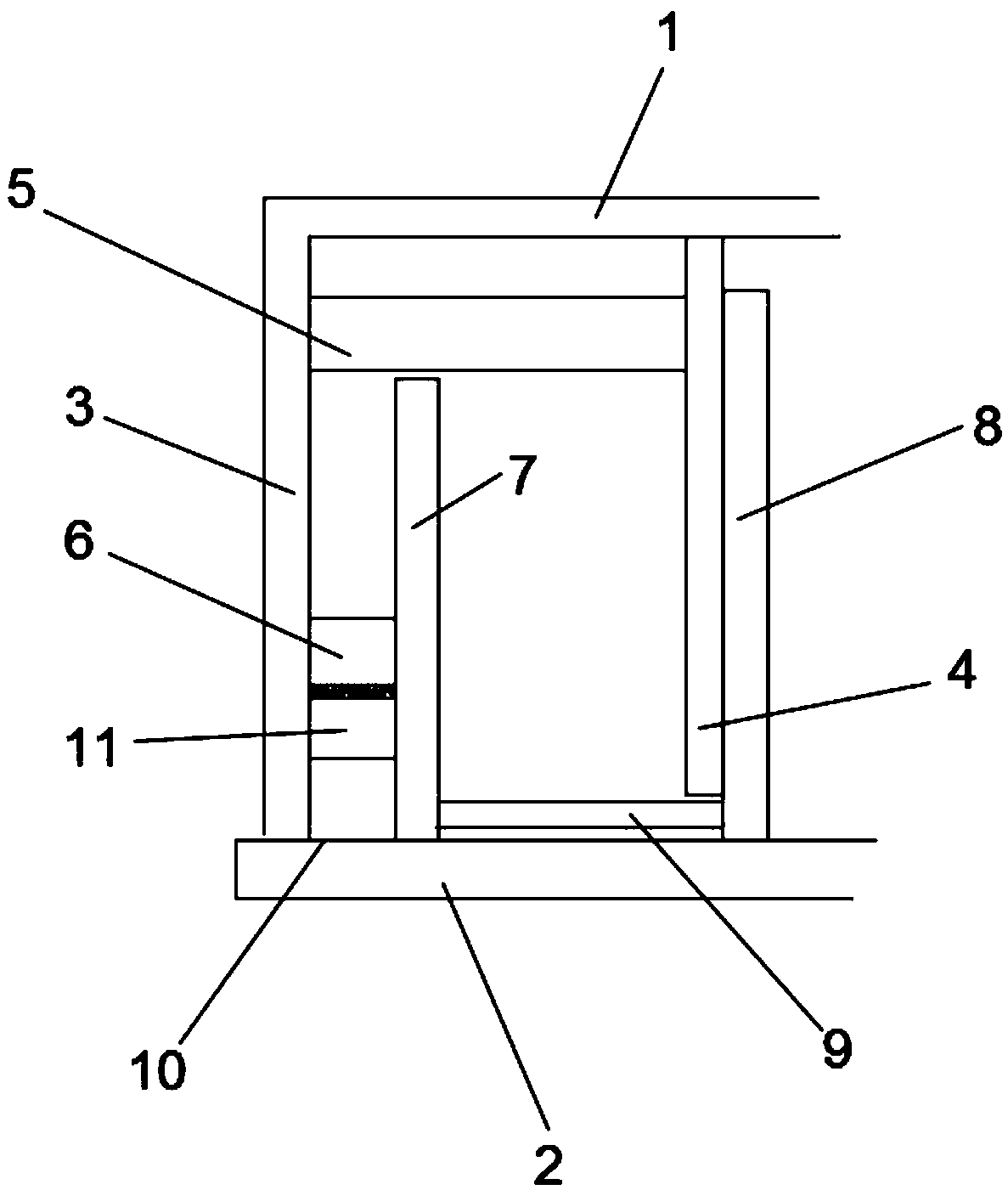

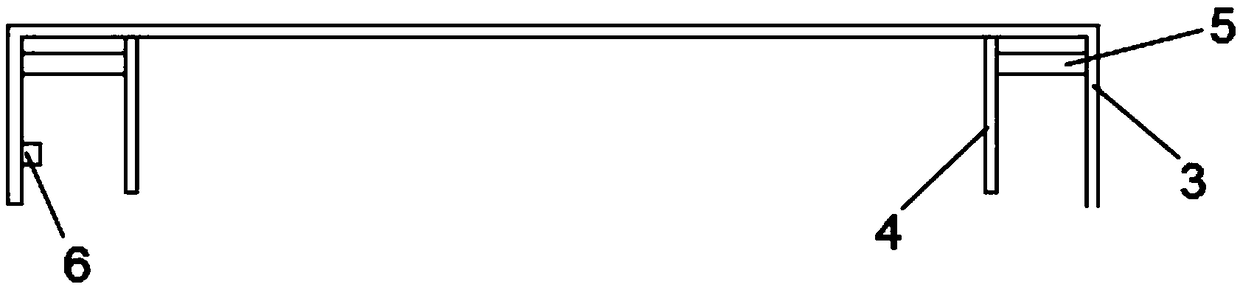

The invention discloses a modular animal digestive tract in-vitro simulation system and a human intestinal tract simulation method thereof. The modular animal digestive tract in-vitro simulation system comprises at least one animal digestive tract in-vitro simulation unit. Each animal digestive tract in-vitro simulation unit includes a frame, a reaction tank used for simulating a specific digestive tract cavity, and multiple function modules which can complete a specific and relatively independent task of intestinal tract simulation. Each frame is provided with multiple installation positions for installing the function modules and the reaction tank, and the function modules and the reaction tank are installed on the frame detachably. Each function module includes a sensor or a moving part, or includes both the sensor and the moving part. Each function module uses a separate Arduino nano 328 as a control chip, and is connected with an upper computer through a USB serial port. Each frame is equipped with a USB active hub. A USB is responsible for power supply to single chip microcomputers in the function modules and instruction transmission between upper and lower computers. Multiple function modules are integrated in one frame, so that the lab space is saved, the modules can be replaced rapidly, and a faulty module can be checked and replaced without shutdown.

Owner:JINAN UNIVERSITY

Casting manufacturing method of superconducting NbTi alloy

The invention discloses a casting manufacturing method of a superconducting NbTi alloy. The casting manufacturing method comprises the following steps of carrying out purification and ingot casting of high-melting point metal Nb to obtain an Nb rod, pressing low-melting point sponge active metal Ti into a semi-cylindrical tile, carrying out assembly welding of the Nb rod and the semi-cylindrical tile in an inert gas protective atmosphere to obtain a consutrode, and carrying out electric arc melting more than twice. The superconducting NbTi alloy obtained by the casting manufacturing method has no impurities, high uniformity, less interstitial elements and good plasticity, and is conducive to manufacture of thin core rods suitable for large-scale application and alloy materials having a high current-carrying capability and a low cost.

Owner:NINGXIA ORIENT TANTALUM IND

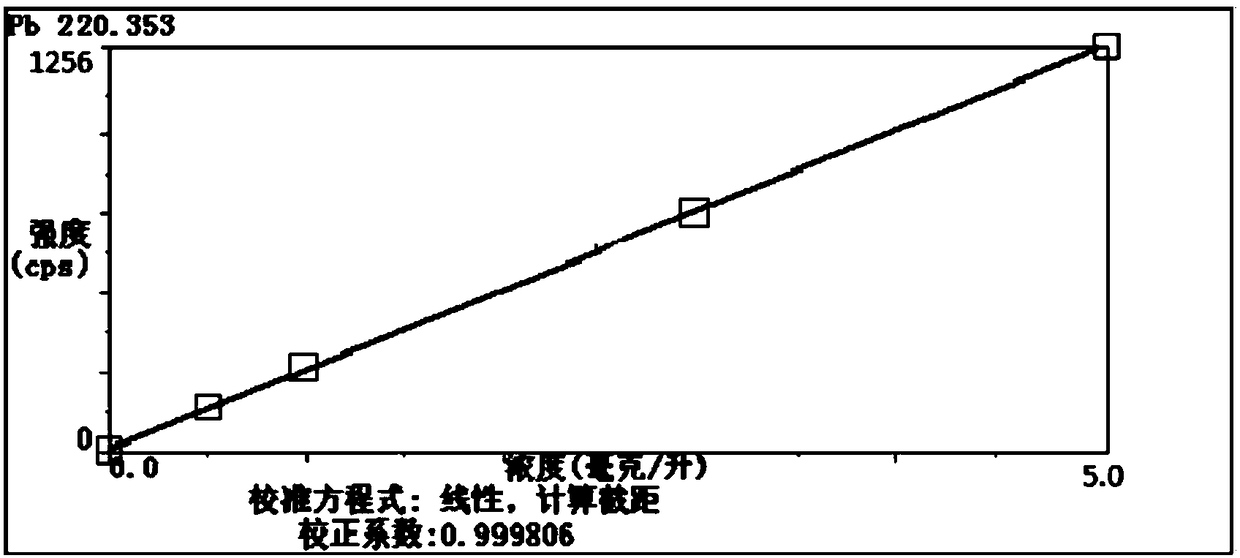

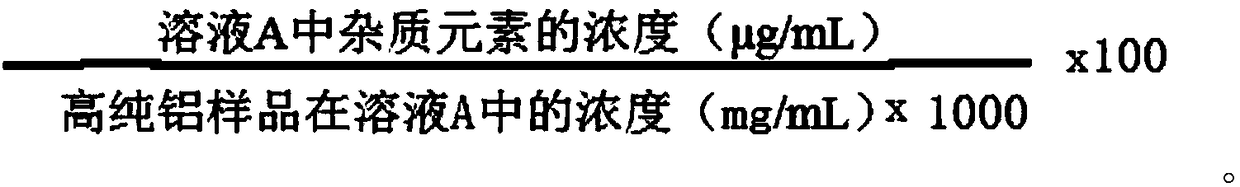

Method for determining impurity elements in high-purity aluminum through microwave digestion-inductive coupled plasma optical emission spectrometer

InactiveCN108375568ALow detection limitAccurate measurementPreparing sample for investigationAnalysis by thermal excitationOptical Emission SpectrometerMethod test

The invention provides a method for determining impurity elements in high-purity aluminum through a microwave digestion-inductively coupled plasma emission spectrometer and belongs to the technical field of analysis and test. The invention provides an analysis method for determining 20 impurity elements including Ag, Ba, Bi, Cd, Co, Cu, Ga, Fe, In, Li, Mg, Mn, Mo, Pb, Sb, Ti, V, Sr, Zn and Zr in the high-purity aluminum through a microwave digester and an inductive coupled plasma optical emission spectrometer (ICP-OES) by adopting a standard curve method. A sample is dissolved into a sealed high-pressure microwave digestion tank by utilizing a proper amount acid, so as to avoid external factor pollution better. Optimal working parameters of an instrument are determined through a single-factor experiment. A standard curve-method test sample is selected so that matrix interference is reduced. The method is a simple, rapid and accurate modern detection technology capable of determining 20elements in one step.

Owner:BEIJING UNIV OF TECH

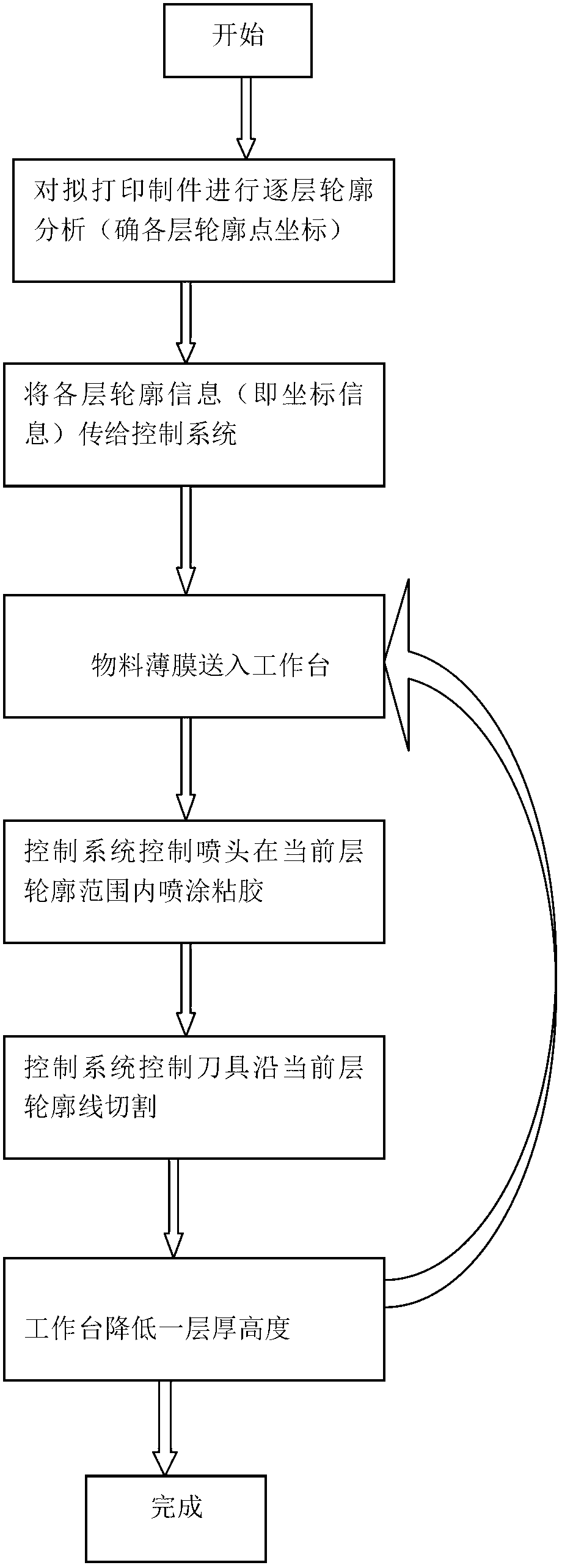

3D (Three-dimensional) desktop printing method and system

The invention relates to a 3D (Three-dimensional) desktop printing method and system. Compared with the traditional method, the difference is characterized in that an adhesive is only sprayed in the current layer of contour area in the printing process, and the cutting is carried out on a layer after the adhering is carried out on the layer. The method and the system provided by the invention have the beneficial effects of greatly saving processing auxiliary materials and reducing the manufacturing cost of processing equipment.

Owner:陈功举

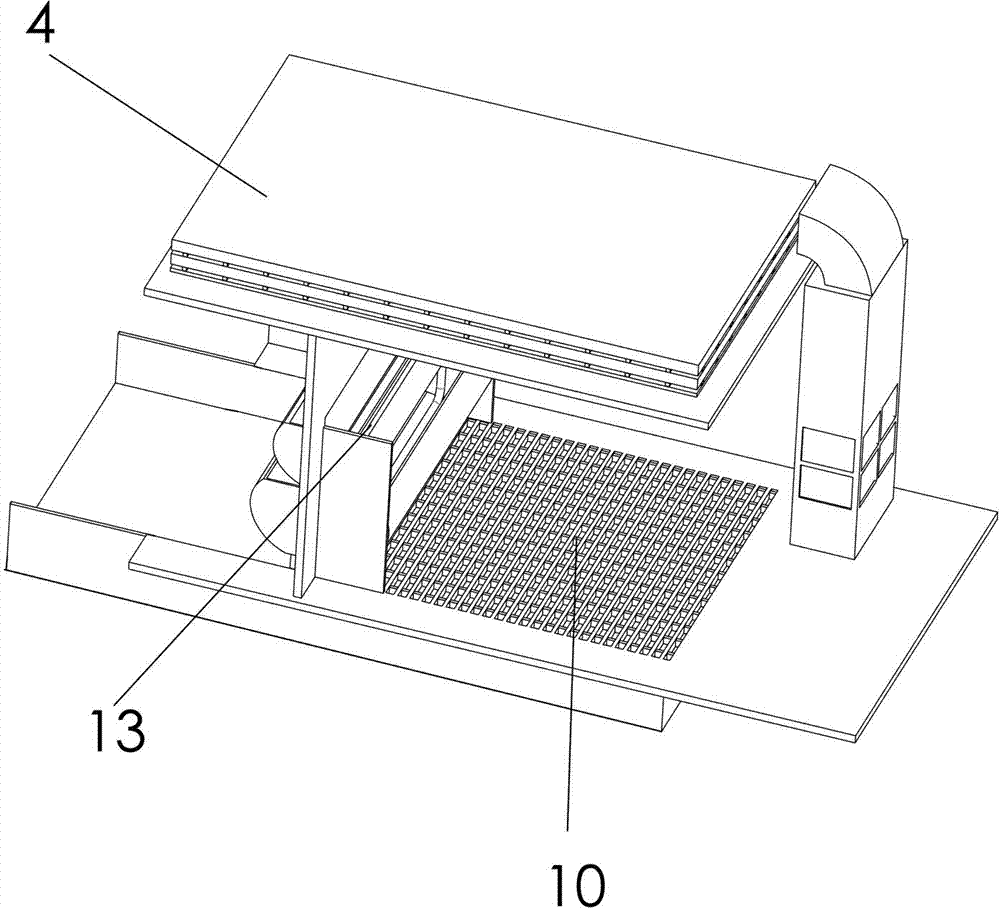

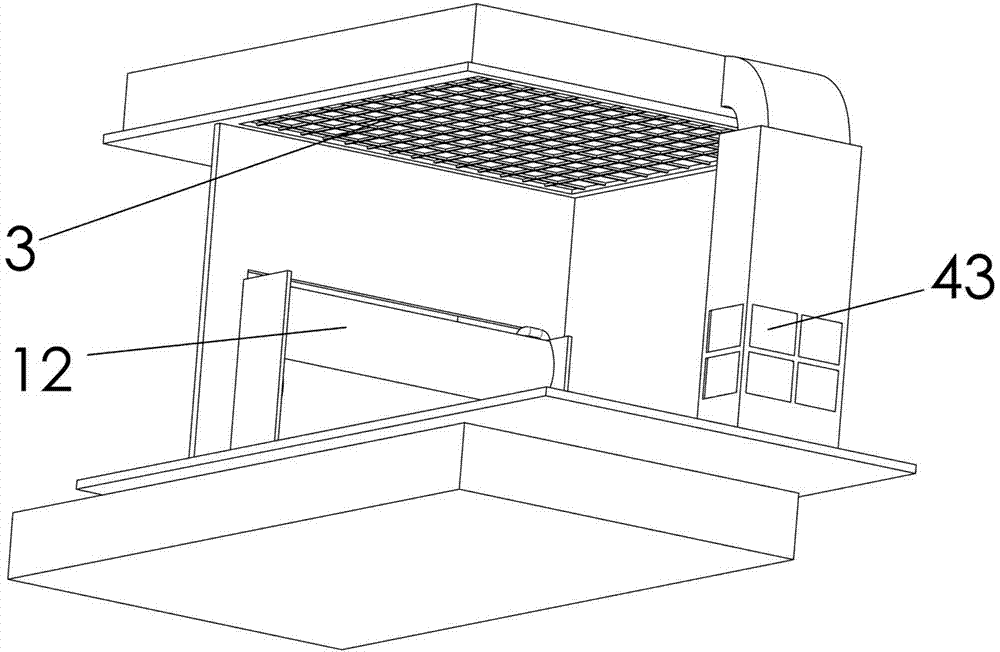

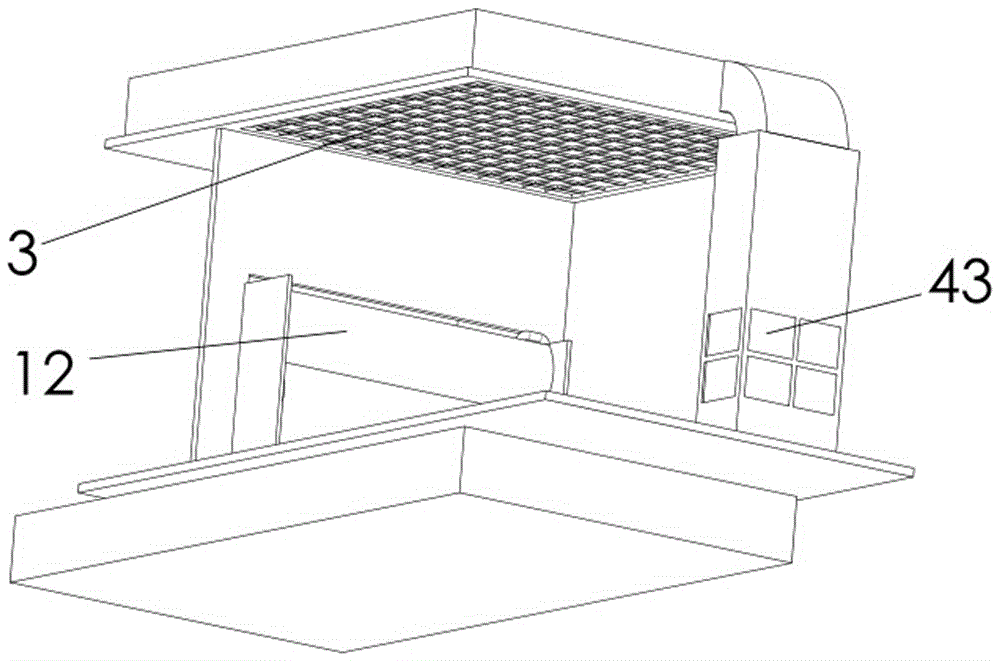

Novel odorless pain room

InactiveCN104249047ASmooth circulationLight lacquer smellLiquid surface applicatorsUsing liquid separation agentFiberSewage

The invention belongs to the field of furniture processing, and particularly relates to a novel odorless pain room. The novel odorless pain room comprises a room formed by enclosure of walls and a roof, an indoor floor located in the room body, an air supply device arranged outside the room body and a deodorizing and sewage draining device arranged in the room body. A roof net rack is arranged under the roof, fiber cotton is laid on the roof net rack, an air supply chamber is formed between the filter cotton and the roof, the air supply device comprises a suction fan case, a suction opening arranged in the suction fan case and an air supply pipe, the deodorizing and sewage draining device comprises a drain tank and a pain leaking net rack set up on the drain tank, and a sewage draining exit is arranged in the wall. Sprayed floating paint and air with paint odor are downwardly blown to the drain tank through filtered natural air blowing down from the roof downwardly so as to be absorbed by water and discharged out of the paint room via the sewage draining exit. A water tank is further arranged at the sewage draining exit, water overflowing from the water tank forms a water curtain to filter air passing through the sewage draining exit, and accordingly paint and paint odor in air discharged from the paint room to the sewage draining exit are removed.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

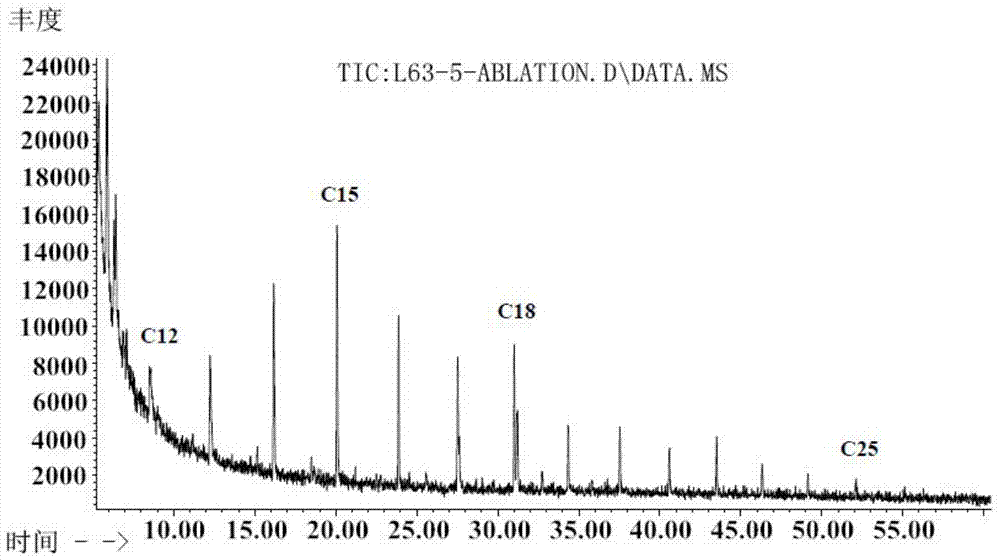

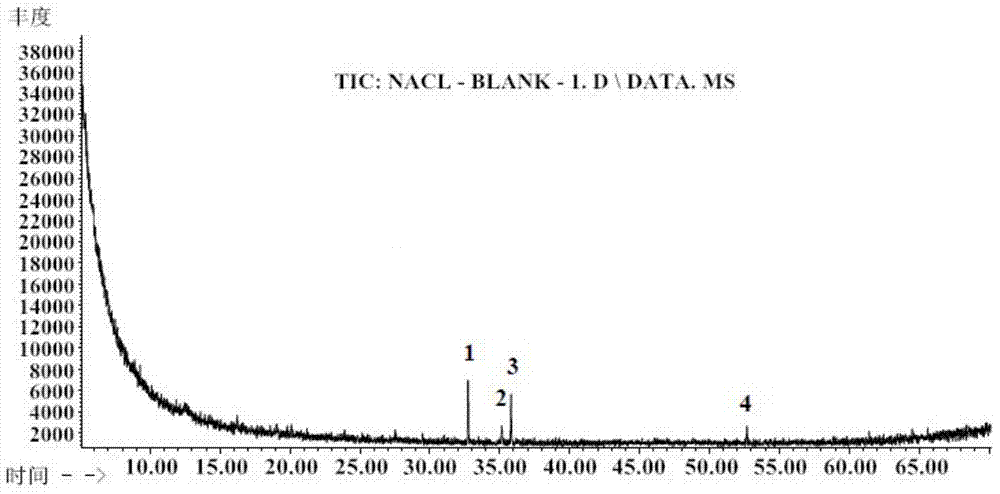

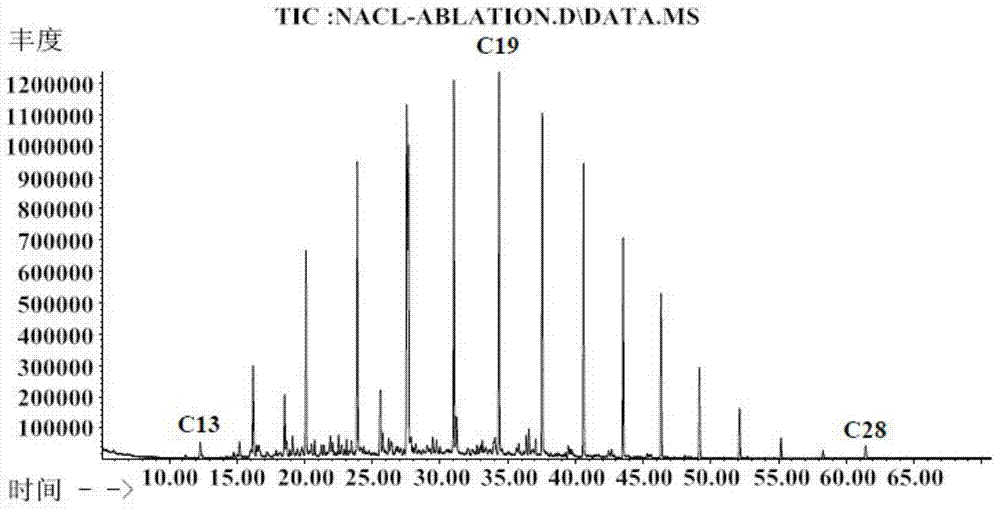

Oil gas inclusion component sampling method

ActiveCN104713742ARemain relatively independentPromote enrichmentComponent separationWithdrawing sample devicesAdditive ingredientEngineering

A method of sampling ingredients of an oil-bearing inclusion includes a) providing a first container and a second container, an external diameter of the first container being smaller than an internal diameter of the second container, and the first and second containers both being transparent; b) adding a solvent into the first container and sealing said first container; c) adding an oil-bearing inclusion sample into the second container, and putting the first container that contains the solvent and is sealed in step b) into the second container; and d) using a laser to ablate the oil-bearing inclusion sample contained in the second container that is sealed in step c), and using the laser to break an end portion of the first container close to the sample on condition that the second container is maintained complete, so as to allow the solvent in the first container to enter the second container.

Owner:CHINA PETROLEUM & CHEM CORP +1

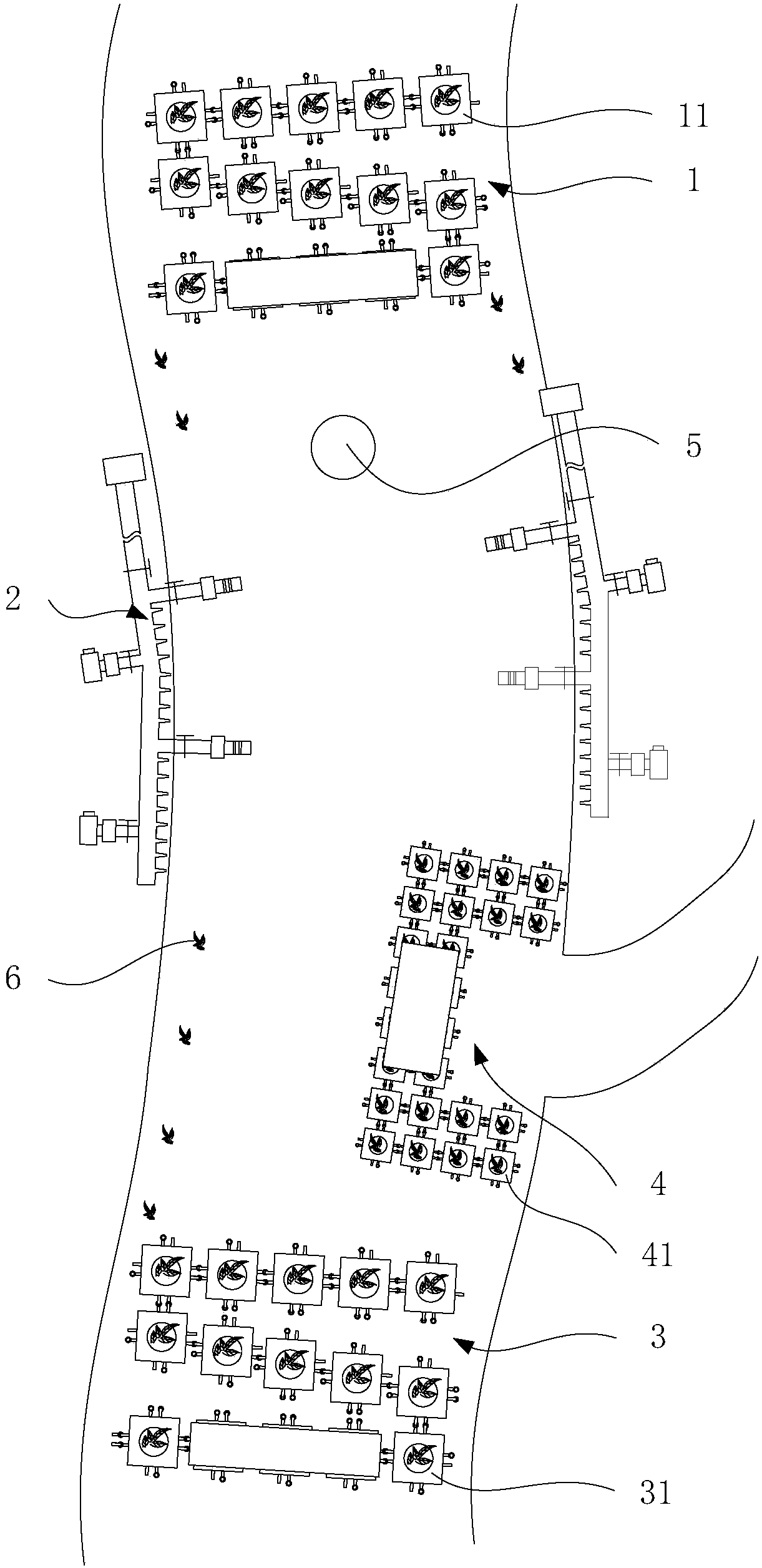

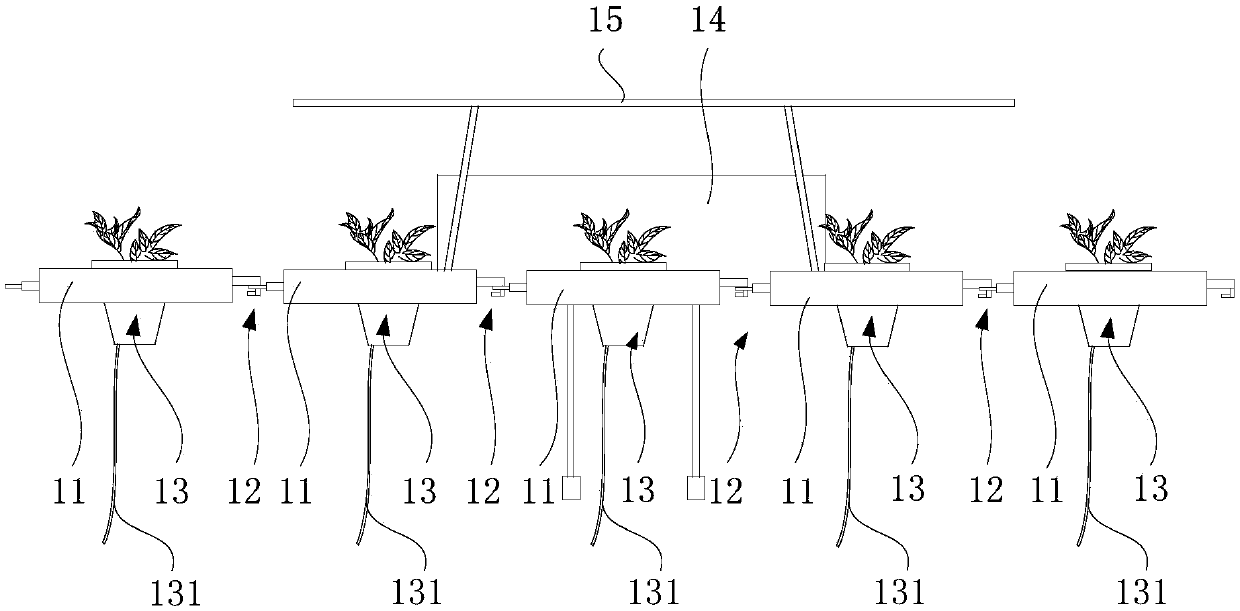

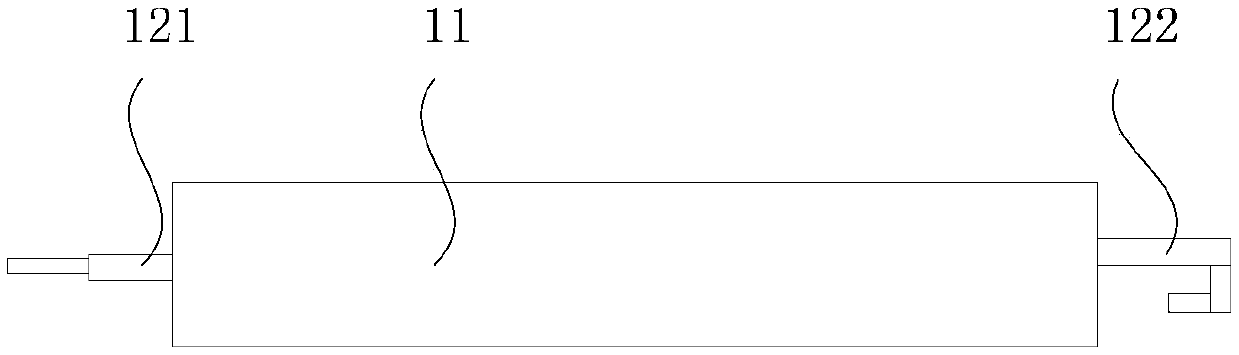

River and lake ecological restoration system

PendingCN108046438AReduce flow ratePrevent backflowWater resource protectionBatteries circuit arrangementsEngineeringEnvironmental engineering

The invention provides a river and lake ecological restoration system and relates to the technical field of river and lake water purification. The river and lake ecological restoration system providedby the invention comprises an upstream ecological purification floating island, a mid-stream aerated and medicated fountain, a downstream ecological purification floating island and an ecological pollution isolation fence, wherein the upstream ecological purification floating island is arranged on the upstream of a river or a lake, for the treatment of upstream river and lake water; the mid-stream aerated and medicated fountain is arranged on the bank of the river or the lake, for aeration and medication into mid-stream river and lake water; the downstream ecological purification floating island is arranged on the downstream of the river or the lake, for the treatment of downstream river and lake water; the ecological pollution isolation fence is arranged at a tributary entrance or a pollution discharging opening of the river or the lake for the interception of foreign pollutants. The river and lake ecological restoration system provided by the invention can more comprehensively treatthe upstream, the mid-stream and the downstream of the river or the lake and can simultaneously intercept the foreign pollutants to realize the systematic management of the river or the lake, therebybeing suitable for the large-area river or lake.

Owner:广东中环生态科技有限公司

Determining method for trace nickel in high-salinity wastewater

InactiveCN105954265ALow detection limitAccurate measurementAnalysis by thermal excitationDistilled waterWastewater

The invention provides a determining method for trace nickel in high-salinity wastewater. The determining method comprises the following steps: firstly, taking the high-salinity wastewater containing the trace nickel as a water sample; secondly, adding acid in the water sample for dissolving and then using distilled water to reach constant volume, respectively taking a plurality of parts of water samples with the constant volumes, not adding a nickel standard solution into one water sample, and adding nickel standard solutions of different amounts into other parts to obtain one part of to-be-determined solution and one group of sample solutions with concentration gradient; thirdly, selecting a spectral line for determining nickel to be 231.6nm, and using an inductive coupling plasma emission spectrograph to respectively test the to-be-determined solution and the group of sample solutions to obtain corresponding spectral intensity data; fourthly, using the spectral intensity data of the sample solution to map the addition amount of the nickel standard solution, and fitting to obtain a linear curve; fifthly, calculating the concentration of nickel in the to-be-determined solution according to the linear curve and the spectral intensity data of the to-be-determined solution, and then calculating the concentration of the nickel in the water sample according to the dilution multiple of the water sample. According to the method, the workload can be reduced; the method has the advantages of high determination speed, high accuracy and good precision.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST +1

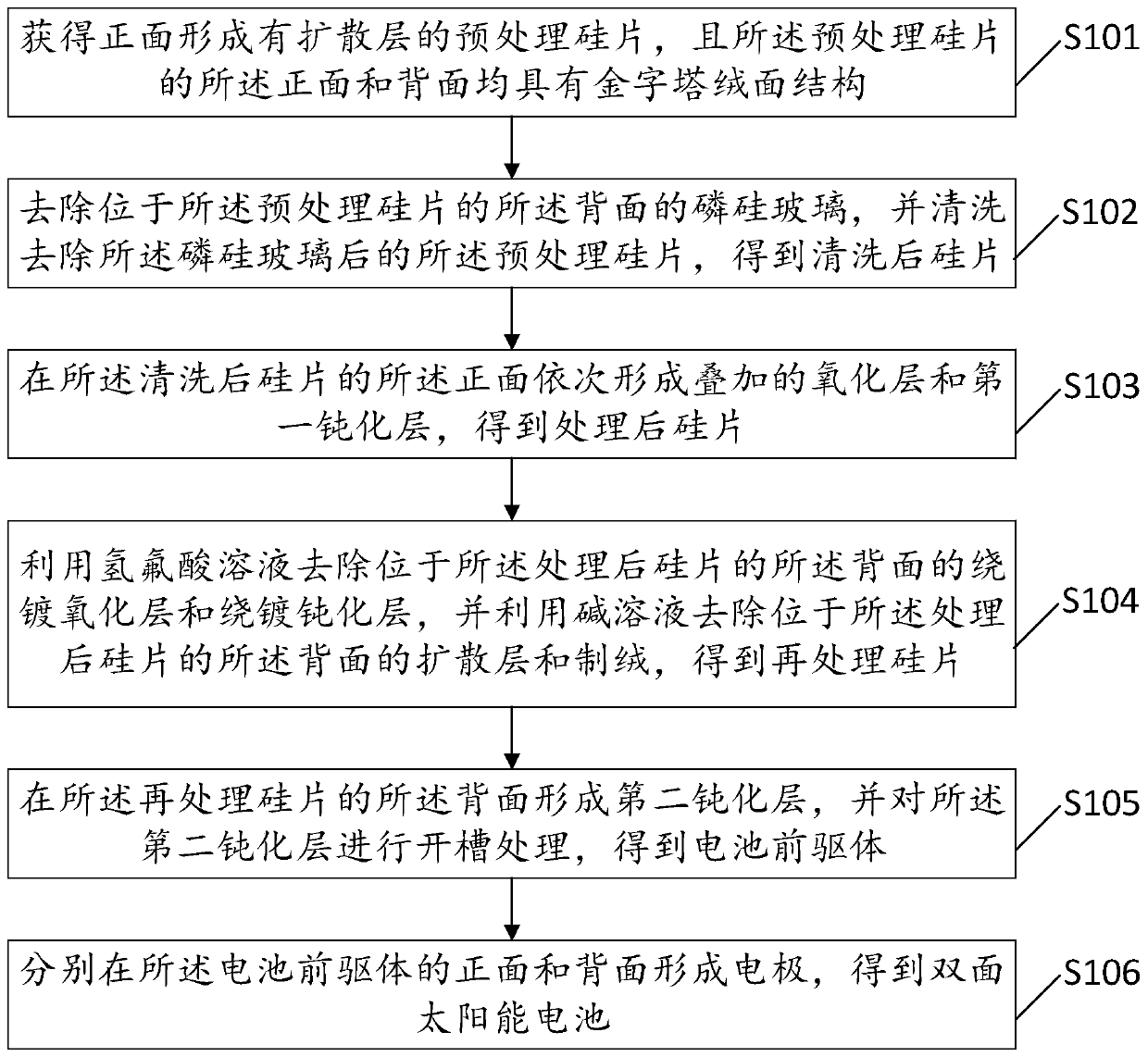

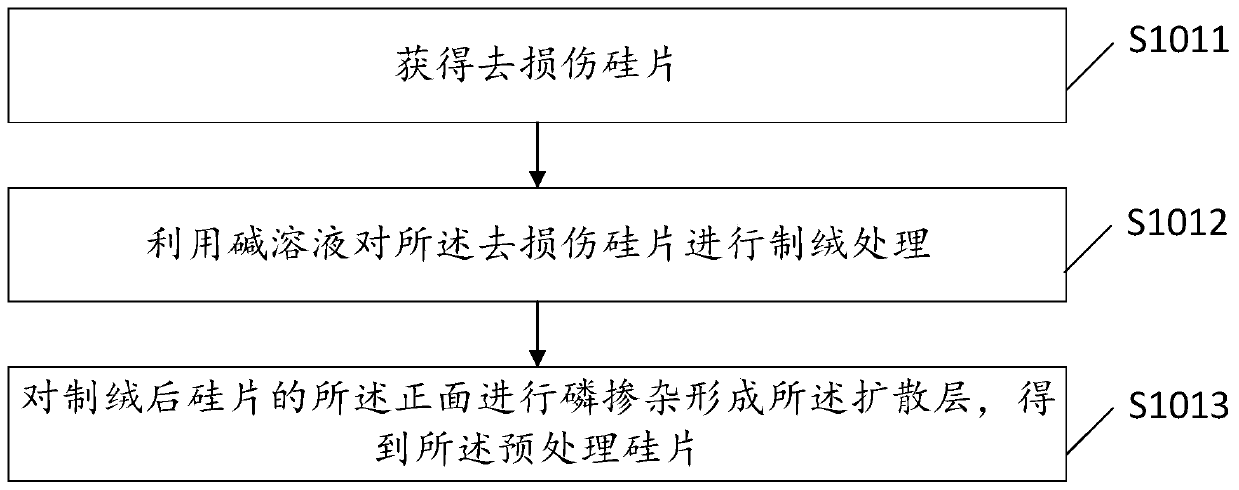

Double-sided solar cell and manufacturing method thereof

ActiveCN111509089AImprove efficiencyIncrease the duplex rateFinal product manufacturePhotovoltaic energy generationHydrofluoric acidSolar battery

The invention discloses a method for manufacturing a double-sided solar cell, and the method comprises the steps: obtaining a preprocessing silicon wafer with a diffusion layer formed on the front surface, and enabling the front surface and back surface of the preprocessing silicon wafer to have pyramid suede structures; removing phosphorosilicate glass on the back surface of the preprocessing silicon wafer, and cleaning the preprocessing silicon wafer from which the phosphorosilicate glass is removed to obtain a cleaned silicon wafer; sequentially forming an oxide layer and a first passivation layer which are superposed on the front surface of the cleaned silicon wafer to obtain a treated silicon wafer; removing the winding plating oxide layer and the winding plating passivation layer onthe back surface of the treated silicon wafer by using a hydrofluoric acid solution, and removing the diffusion layer and texturing on the back surface of the treated silicon wafer by using an alkaline solution to obtain a retreated silicon wafer; forming a second passivation layer on the back surface of the retreated silicon wafer, and slotting the second passivation layer to obtain a battery precursor; forming electrodes on a front surface and a back surface of the battery precursor to obtain the double-sided solar cell, thereby effectively improving the double-sided rate of the cell and reducing the color difference between the front surface and the back surface.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

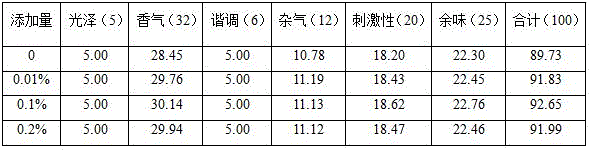

Antidesma bunius extract and preparation method and application in cigarettes thereof

InactiveCN107361398ANo residueWidely distributedTobacco preparationTobacco treatmentWater vaporAntidesma bunius

The invention relates to a preparation method of May tea extract, which comprises the following steps: 1) Ultrasonic extraction: adding dried and pulverized May tea powder into 85-95% ethanol at a mass ratio of 1:4-20 Ultrasonic extraction, filtering after extraction to obtain filtrate I and residue I; 2) Steam distillation extraction: Add residue I to distilled water at a mass ratio of 1:4-20 for reflux extraction, and filter after extraction to obtain filtrate II and residue II; 3) Concentration by vacuum distillation: Mix the filtrate I and filtrate II evenly, and then distill under reduced pressure to obtain a concentrated solution, which is the May tea extract. The May tea extract was added to cigarettes for sensory evaluation, and the results showed that: compared with the blank control cigarettes, the May tea extract of the present invention made the cigarette smoke harmonious, the smoke was rich, the body fluid was sweetened, and the cigarette smoke was reduced. The dry feeling of cigarettes significantly improves the smoking quality of cigarettes, which is of great promotion and application value.

Owner:CHINA TOBACCO HENAN IND

Production process of magnesium chloride granules

ActiveCN103145159AAdvanced process designEasy to operateMagnesium chloridesProduction linePhysical chemistry

The invention discloses a production process of magnesium chloride granules. The production process comprises the following steps of: crushing crystallized magnesium chloride, then, placing the crushed magnesium chloride into a dissolving tank, stirring the crushed magnesium chloride, then, standing for settlement, inspecting the baume degree of the liquid not to be lower than 33.5Be', and primarily filtering the liquid in the dissolving tank to obtain primary filtrate magnesium chloride; naturally settling the primary filtrate magnesium chloride for at least three days, then, sequentially placing the primary filtrate magnesium chloride into a two-effect separator and a one-effect separator to carry out steam-liquid separation to obtain liquid magnesium chloride; and delivering the liquid magnesium chloride to a dust-free pelleting chamber through a pipeline to pellet to obtain finished products of the magnesium chloride granules. The method is advanced in process design, strong in operability, controllable in process parameter and capable of realizing large-scale industrial production; the prepared product is high in purity and capable of meeting the requirement of a high-quality product; the magnesium chloride granules are high in dissolving speed and clear, transparent and free of impurities after being dissolved; and an automatic production line is adopted, and the product is high in stacking density and not easy to air slake.

Owner:LIANYUNGANG RIFENG CALCIUM & MAGNESIUM

Production method of bitter melon wine

The invention relates to a production method of a bitter melon wine. The production method comprises the following steps: (1) selecting bitter melons with small volumes and round bodies; (2) planting according to normal planting manners of melons; (3) bridging frames into crossed frames when a melon vine grows to be 35cm-50cm in length, carrying out fixing between two vertical frames, forming each crossed frame, by utilizing short bamboo rods, and transversely pulling the rods among the crossed frames; (4) removing flower buds when the bitter melon grows to be 15cm-25cm in length, putting the flower buds into small-caliber large-belly wine bottles, hanging the wine bottles on transverse rods and the short bamboo rods, and sealing the wine bottles by utilizing brown paper; (5) harvesting after fruits in the hung wine bottles grow to be 15cm-25cm in length and 3cm-4cm in diameter; (6) inverting, unsealing and washing the wine bottles, and draining off moisture; (7) putting the wine bottles which are used for containing the bitter melons into clean water at 80-90 DEG C, and blanching for 2-3 minutes; (8) draining off the water in the wine bottles after blanching, sealing and rapidly cooling the wine bottles, and draining off the moisture; (9) filling brewed 32%vol-38%vol white wine into the wine bottles, examining impurities, and finally capping and storing, so as to obtain the finished wine after one year.

Owner:BEIPIAO HUAYI WINE

Preparation method of hyaluronic acid for eye drops

InactiveCN110922505APrevent inflowWidely applicable to large-scale productionSenses disorderPharmaceutical delivery mechanismActivated carbonOrganic chemistry

The invention provides a preparation method of hyaluronic acid or salt thereof for eye drops. The preparation method comprises the following steps: adding ethanol into end-point fermentation liquor toprecipitate an HA crude product; dissolving, filtering, adjusting the pH value of the filtrate to 6.0-7.0, allowing the filtrate to pass through a polar resin column, then adjusting the pH value to 5.0-6.0, allowing the filtrate to pass through a non-polar resin column, allowing the filtrate to pass through a 0.2 [mu] m filter element, adding ethanol, precipitating, dehydrating and drying to obtain the HA for the eye drops. According to the method, the activated carbon is replaced by the adsorption resin so that the problem of impurity removal in the production of the HA for the eye drops issolved, the problem of floccule precipitation of the eye drop products due to the fact that a small amount of activated carbon particles flow into the HA products is avoided and the percent of pass ofthe eye drop products is increased. Meanwhile, the adsorption resin is renewable and can be repeatedly used after being treated. The resin column is adopted, operation is carried out in a closed system, external pollution is reduced and the method is widely suitable for large-scale production and use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

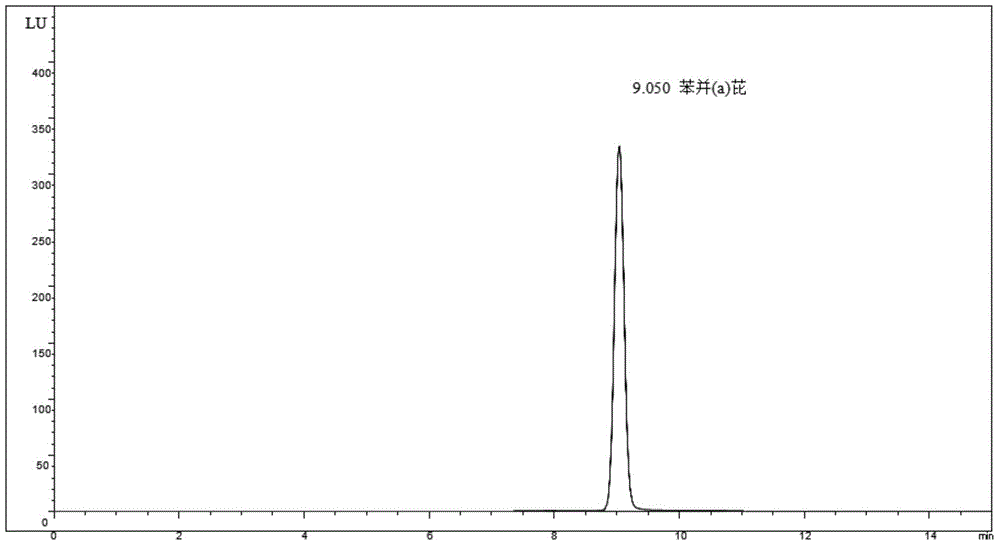

Pretreatment method of benzo (a) pyrene collected by glass fiber filter paper

ActiveCN105136537AHigh desorption recovery efficiencyUtensils are easy to getComponent separationPreparing sample for investigationPretreatment methodDesorption

The present invention discloses a pretreatment method of benzo (a) pyrene collected by glass fiber filter paper, first, glass fiber filter paper with the collected benzo (a) pyrene is cut, and put into a brown headspace sample bottle, then the headspace sample bottle is continued to be added with methanol as a desorption solvent, and then added with a certain amount of alumina, the alumina can absorb and purify interference impurities in a sample; the headspace sample bottle is sealed, and put into an ultrasound device with circulating cooling water for ultrasound desorption for a period of time; finally the headspace sample bottle is taken out, and put into a centrifuge for centrifuging for a period of time at a set rotational speed, and a supernatant is taken and expanded and analyzed by chromatography. The method has the advantages of simple and available appliances, closed pretreatment process, small outside world pollution, fast pretreatment speed, high benzo (a) pyrene desorption recycling efficiency and the like.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

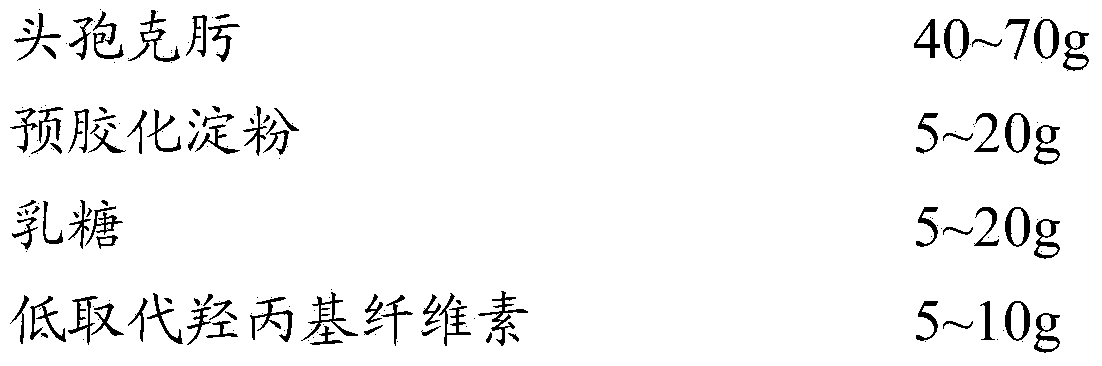

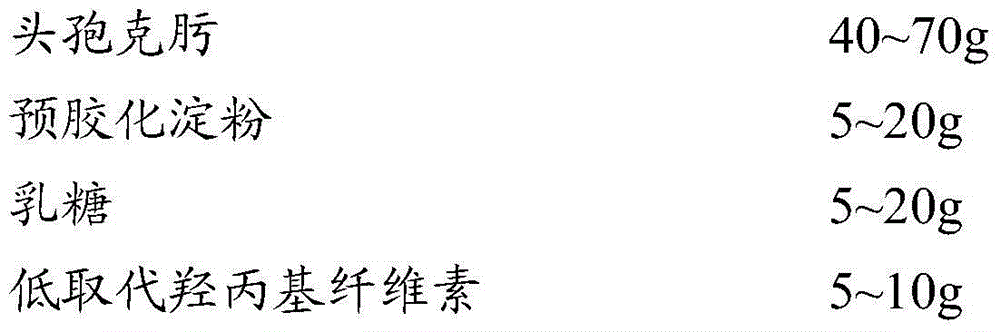

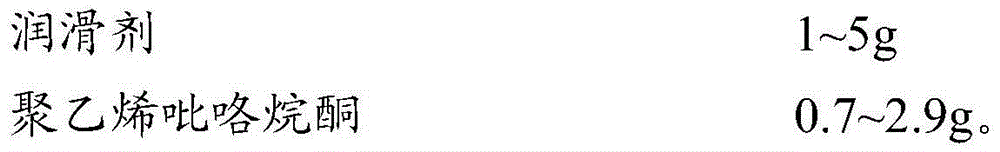

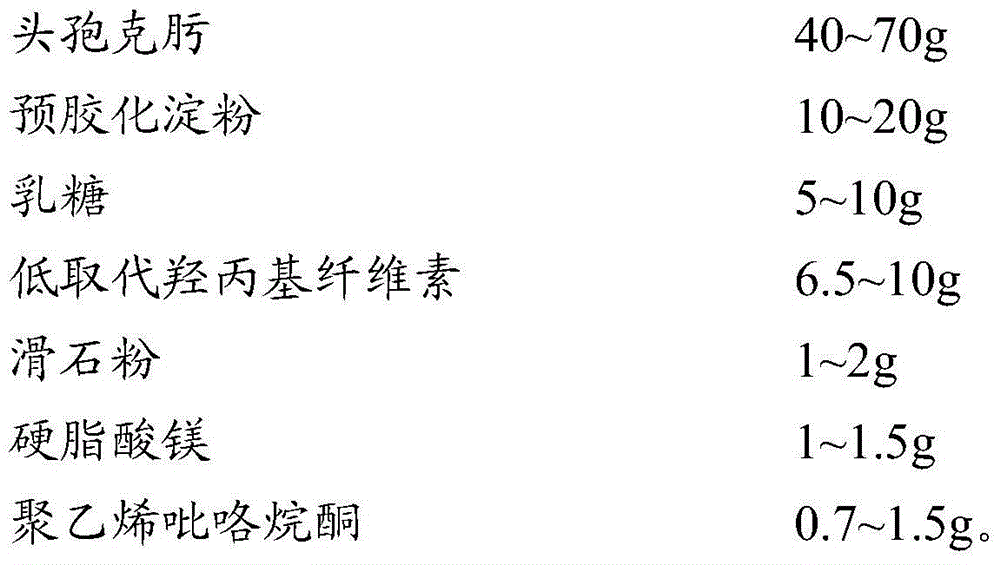

Cefixime dispersible tablets and preparation method thereof

ActiveCN103479587AReduce processReduce pollutionAntibacterial agentsOrganic active ingredientsHigh probabilityLactose

The invention discloses cefixime dispersible tablets. 1000 cefixime dispersible tablets are prepared from the following raw materials in parts by weight: 40-70 g of cefixime, 5-20 g of pregelatinized starch, 5-20 g of lactose, 5-10 g of low-substituted hydroxypropyl cellulose, 1-5 g of lubricant and a proper amount of polyvinylpyrrolidone. The invention also provides a preparation method of the cefixime dispersible tablets. According to the preparation method, granulation is performed by using a one-step granulation method; the three steps of mixing, granulation and drying of the conventional wet granulation are finished in a closed container at one time; according to the process, the problems that the solvent is remained and discolored in the wet granulation process and the pharmaceutical ingredients are heated to be lost in the drying process are avoided, and the problems such as serious dust flying and high probability of cross contamination during tabletting in the dry granulation process are also avoided.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

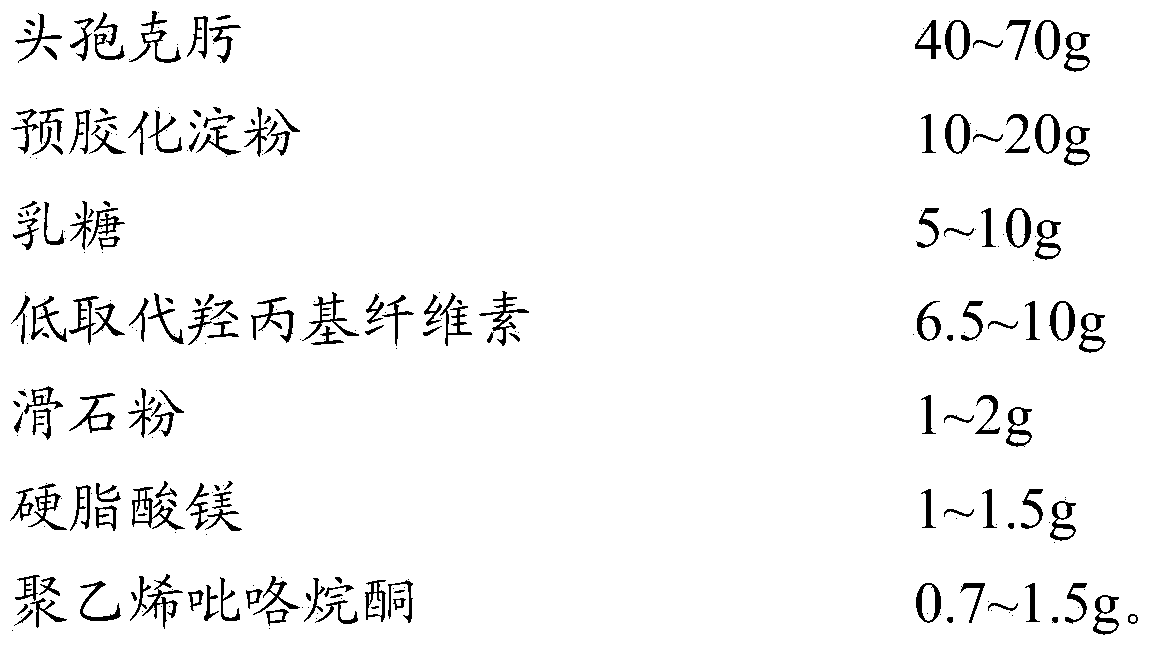

Medical surgical operation anesthetic coating device

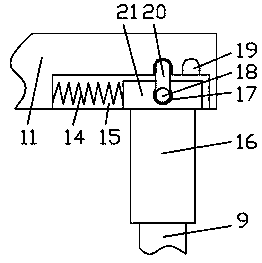

ActiveCN111481815AReduce external pollutionEasy to installAnaesthesiaMedical applicatorsSurgical operationMedical treatment

The invention belongs to the field of medical surgical instruments, and in particular to a medical surgical anesthetic coating device. For aiming at problems that existing equipment is not provided with a protection device, disinfection inconvenience, easy bacteria generation, the mounting or dismounting replacement is inconvenient; operation work intensity is high, use inconvenience, unreasonabledesign problem, the following scheme is provided nowadays. The device comprises a connecting box, the interior of the connecting box is of a cavity structure. A telescopic rod is installed in the connecting box, an inclined push rod is rotatably connected to the side wall of the telescopic rod, a rotating rod is rotatably connected to one end of the inclined push rod, a protective cover is rotatably connected to the lower end of the rotating rod, the upper end of the protective cover is hinged to the connecting box, and a supporting column is fixedly connected to the lower end of the telescopic rod. The device is provided with a protection device, is convenient to disinfect, is not easy to breed bacteria, is convenient to mount or dismount and replace, is low in operation working intensity, is convenient to use and is reasonable in design.

Owner:浙江精美服饰有限公司

Baked corn essence, a preparing method thereof and an application of the essence in cigarettes

ActiveCN106167740AImprove smoking qualityImprove comfortTobacco preparationTobacco treatmentSolventMacroporous resin

A preparing method of baked corn essence is disclosed. The method includes adding water into corn, pulping, adding amylase, hydrolyzing, heating and concentrating under vacuum, reacting by roasting at a high temperature, extracting with a Soxhlet extraction process, adsorbing with macroporous resin, and removing a solvent to obtain the baked corn essence. The baked corn essence is safe, sanitary, low in cost and high in product purity. Prominence is given to baked sweet or coked sweet aroma of cigarettes through evenly spraying the baked corn essence on cut tobacco through a cigarette aroma increasing process, thus improving smoking quality and the sense comfort level.

Owner:CHINA TOBACCO HENAN IND

Yixinshu tablet and preparation method

InactiveCN109288959AUniform particle sizeGreat tastePharmaceutical non-active ingredientsPill deliverySalvia miltiorrhizaMedicine

The invention relates to a Yixinshu tablet and a preparation method. Specifically, the Yixinshu tablet is prepared by extraction of ginseng, radix ophiopogonis, Schisandra chinensis, radix astragali,Salvia miltiorrhiza, Ligusticum wallichii and hawthorn as the raw materials. During preparation of the tablet, 75% ethanol is employed for granulation, has strong viscosity, and is suitable for botanical drugs with loose texture and strong elasticity, and the obtained particles are subjected to size stabilization, the hardness and taste are good, and after tabletting, the obtained tablet has smooth and flat surface, and has good application value.

Owner:GUIZHOU XINBANG PHARMACEUTICAL CO LTD

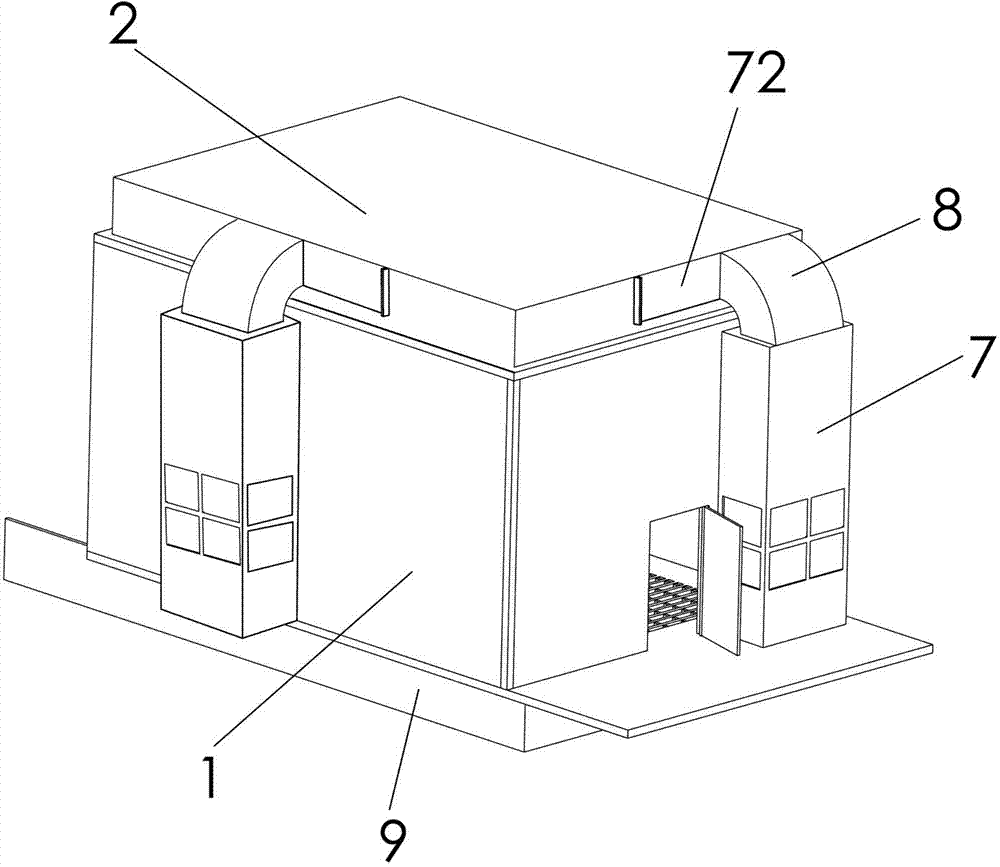

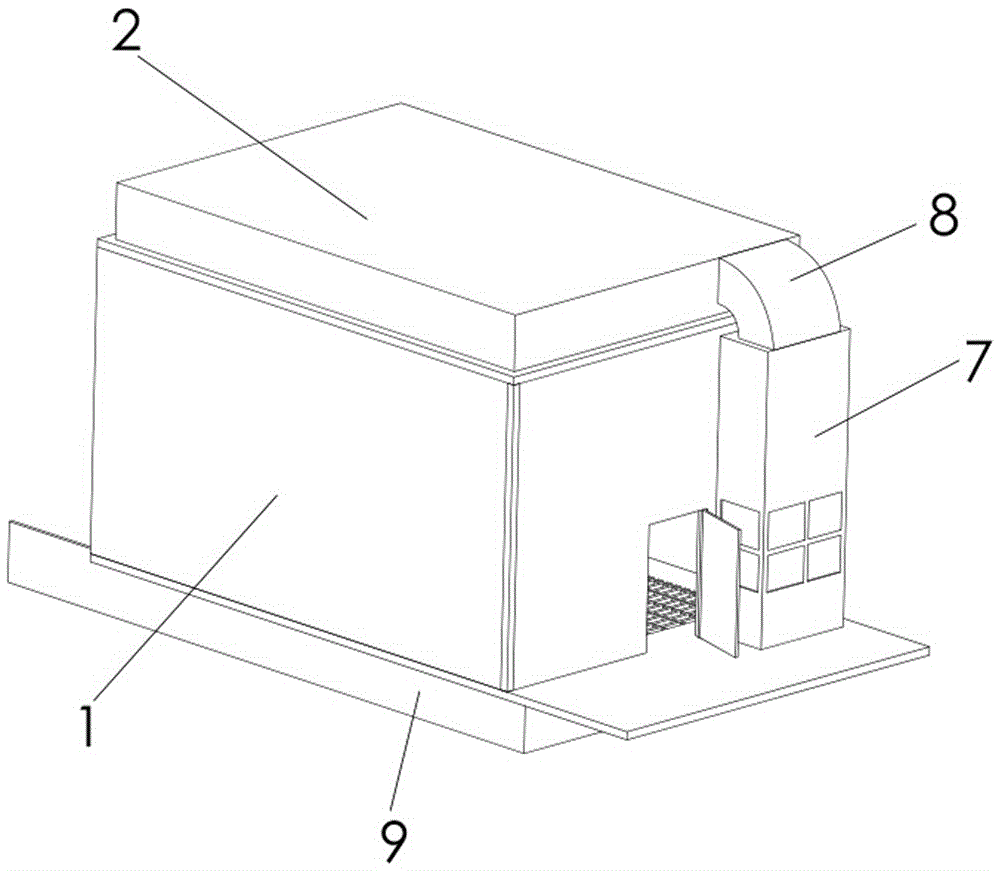

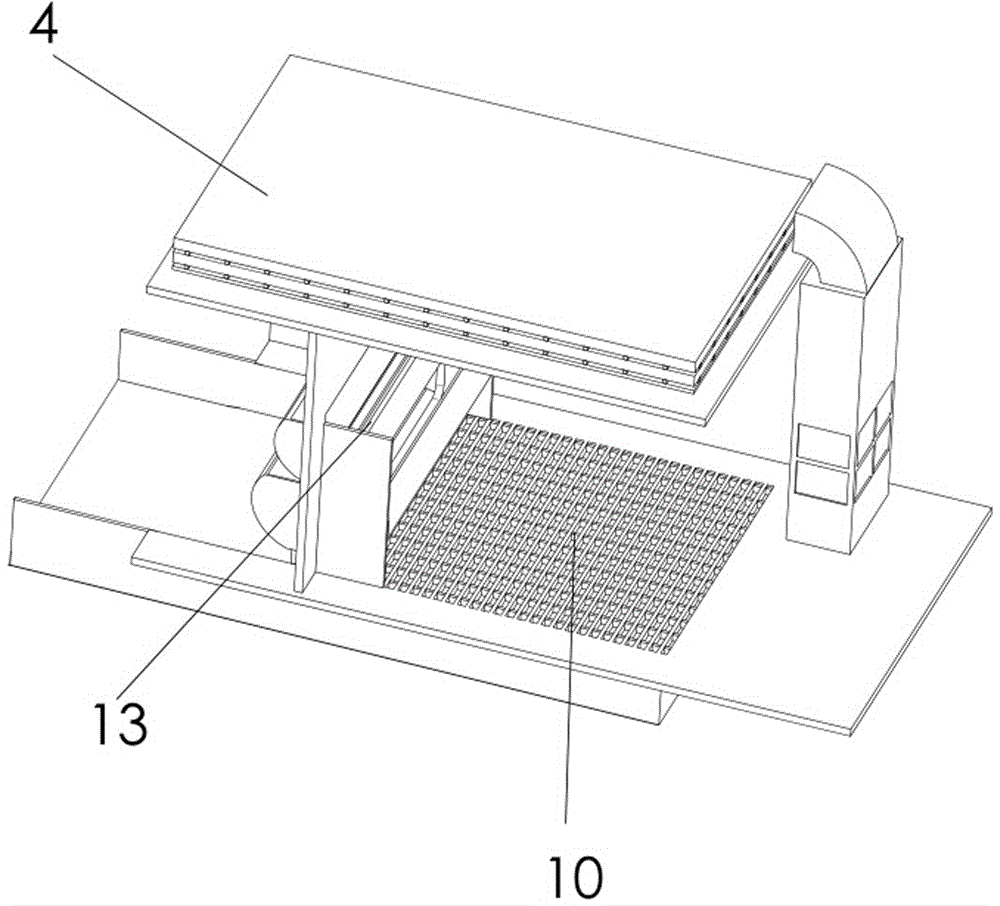

Oil paint house structure

InactiveCN104259039ASmooth circulationLight lacquer smellLiquid surface applicatorsSpraying apparatusFiltrationSewage

The invention belongs to the furniture processing field, and particularly relates to a novel tasteless oil paint house. An oil paint house structure of the novel tasteless oil paint house comprises a house body formed by a wall and a roof in surrounding mode, an indoor floor located in the house body, an air feed device located on the exterior of the house body and an odor removal and sewage draining device arranged in the house body, wherein a top net rack is arranged below the roof, filtration cotton is laid on the top net rack, an air feed cavity is formed between the filtration cotton and the roof, the air feed device comprises a plurality of air draft cases, and air draft mouths and air feed pipes, which are arranged on the air draft cases, the odor removal and sewage draining device comprises a water draining pond and an exposed undercoat net rack erected on the water draining pond, and a sewage outlet is formed in the wall body. According to the oil paint house structure, natural wind which blows downwards from the roof blows oil paint which is sprayed and floats and air with a paint smell downwards to the water draining pond, the oil paint which is sprayed and floats and the air with the paint smell are absorbed by water, and then are discharged out of the tasteless oil paint house through the sewage outlet, a water tank is further arranged on the sewage outlet, water which overflows from the water tank forms a water curtain, air which passes through the sewage outlet is filtered by the water curtain, and therefore the oil paint and the paint smell in the air which is exhausted from the sewage outlet are removed.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

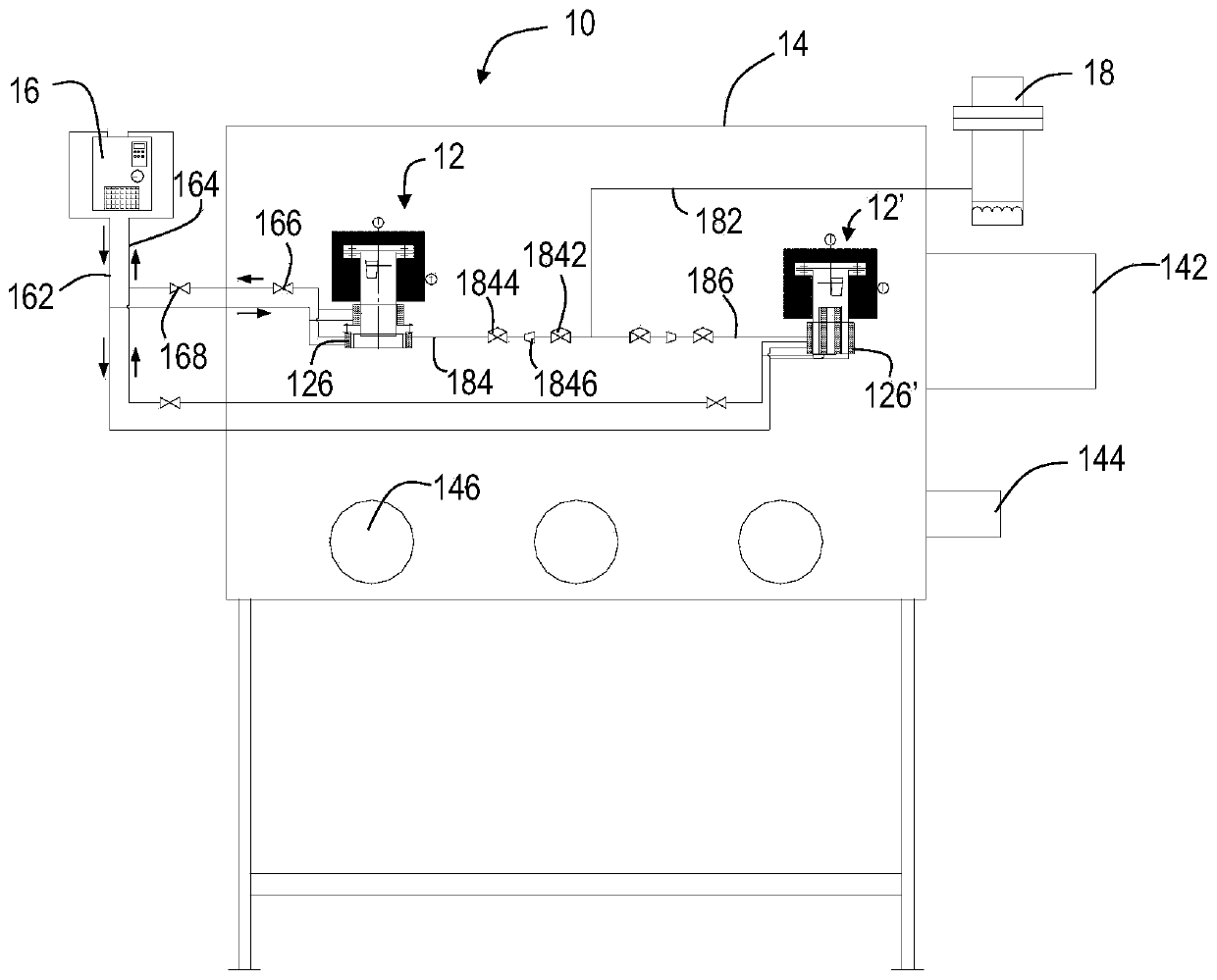

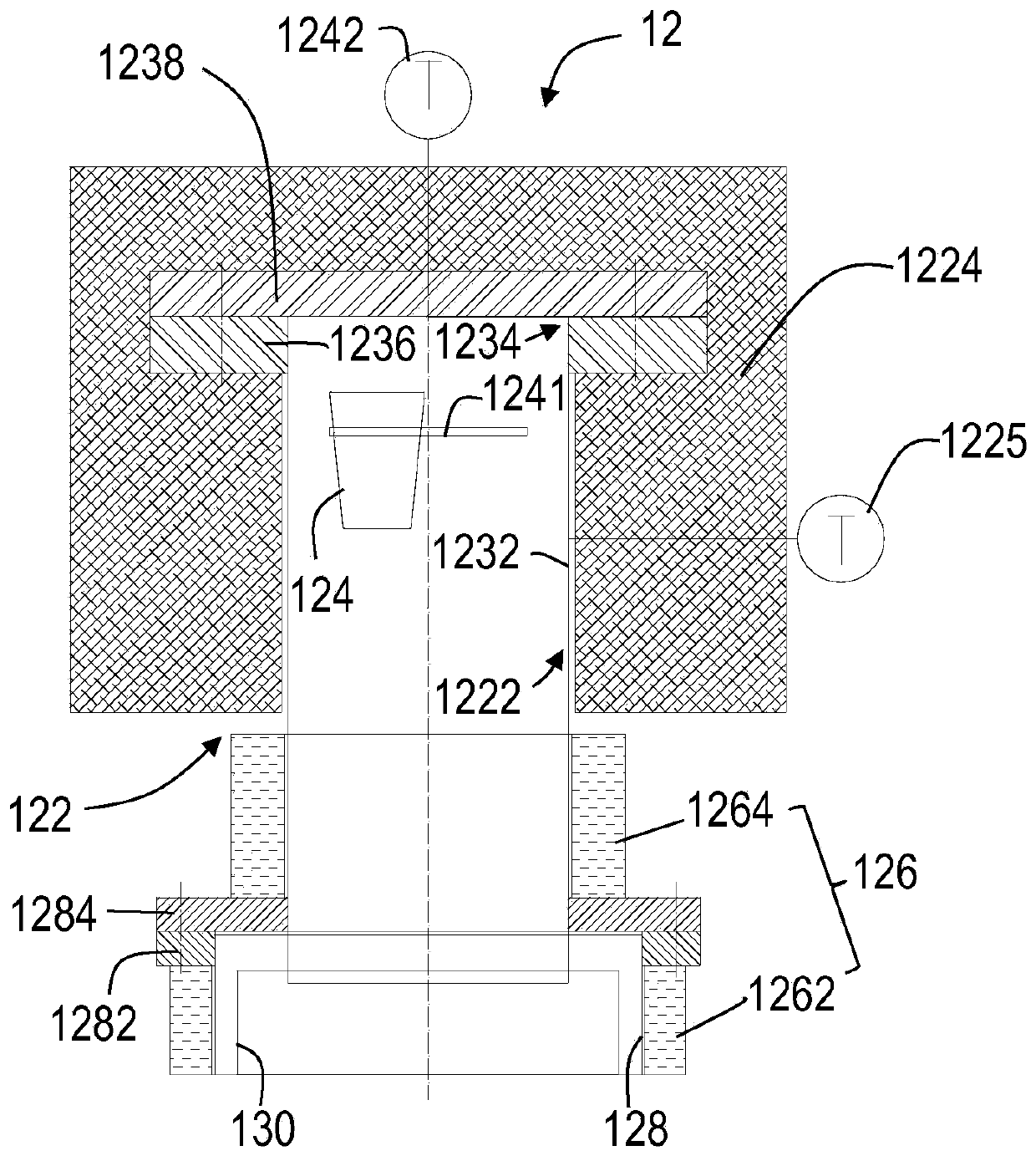

Alkali metal impurity pretreatment apparatus

ActiveCN111485113ASolve complicated problemsAchieve continuous distillationWeighing by removing componentPreparing sample for investigationThermodynamicsDistillation

The invention provides an alkali metal impurity pretreatment apparatus which comprises a distillation unit, an operation box, a cooling unit and a vacuumizing unit. The distillation unit is used for distilling alkali metal containing an impurity so as to separate the impurity from the alkali metal; the operation box is used for accommodating the distillation unit and providing a proper operation environment for the distillation unit; the cooling unit is used for providing a cold source for the distillation unit, so that the alkali metal is converted into a liquid state or a solid state from agas state; and the vacuumizing unit is in fluid communication with an inner cavity of the distillation unit so as to provide a required atmosphere environment for the operation box. According to the alkali metal impurity pretreatment apparatus, a heat source is provided for evaporation of alkali metal through the distillation unit, a cold source is provided for condensation of gaseous alkali metalthrough the cooling unit, a safe and reliable external environment is provided for the whole distillation process and the subsequent treatment process of the alkali metal through the operation box, the risk that the alkali metal is polluted in the distillation process is greatly reduced, and the impurity analysis accuracy is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for in-situ preparation of TEM sample of nanoscale particles in sample with complex structure

ActiveCN111693555AAvoiding back-sputter contamination problemsReduce external pollutionMaterial analysis using wave/particle radiationPhysicsElectrostatic adsorption

The invention provides a method for in-situ preparation of a TEM sample of nanoscale particles in a sample with a complex structure. The method comprises steps of placing a sample on a sample table ina sample cavity of a double-beam electron microscope, arranging a copper net on the sample table, sealing the sample cavity and vacuumizing, observing the surface morphology of the sample by using ascanning electron microscope function, finding out an interested nano particle cluster region, keeping the sample table in a horizontal state, adsorbing the nanoscale particles to a needle tip of thenano manipulator by virtue of electrostatic adsorption force, retracting the nano manipulator, moving the copper net to a position right below the electronic gun, fixing nanoscale particles adsorbed on a needle tip to an edge of a copper hole in the copper net by virtue of the electrostatic adsorption force, and taking out the copper net fixed with the nanoscale particles so as to finish sample preparation. The method is advantaged in that the preparation of the TEM sample of nano-scale particles entrained in a blocky sample or a rare extraterrestrial micron-scale powder sample which has a complex structure and cannot be subjected to polishing treatment can be realized, and the method can be applied to the basic research field of planetary science and planetary detection.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI +1

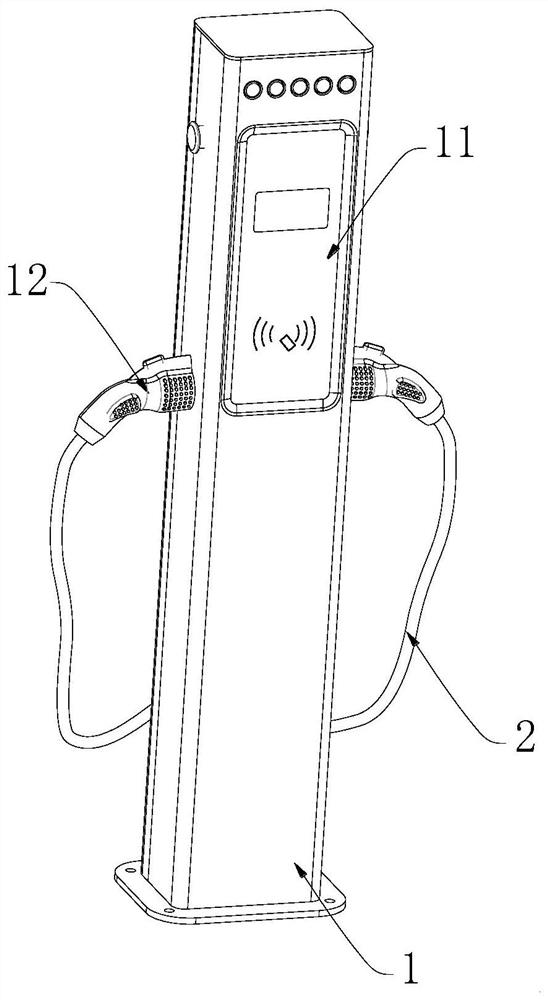

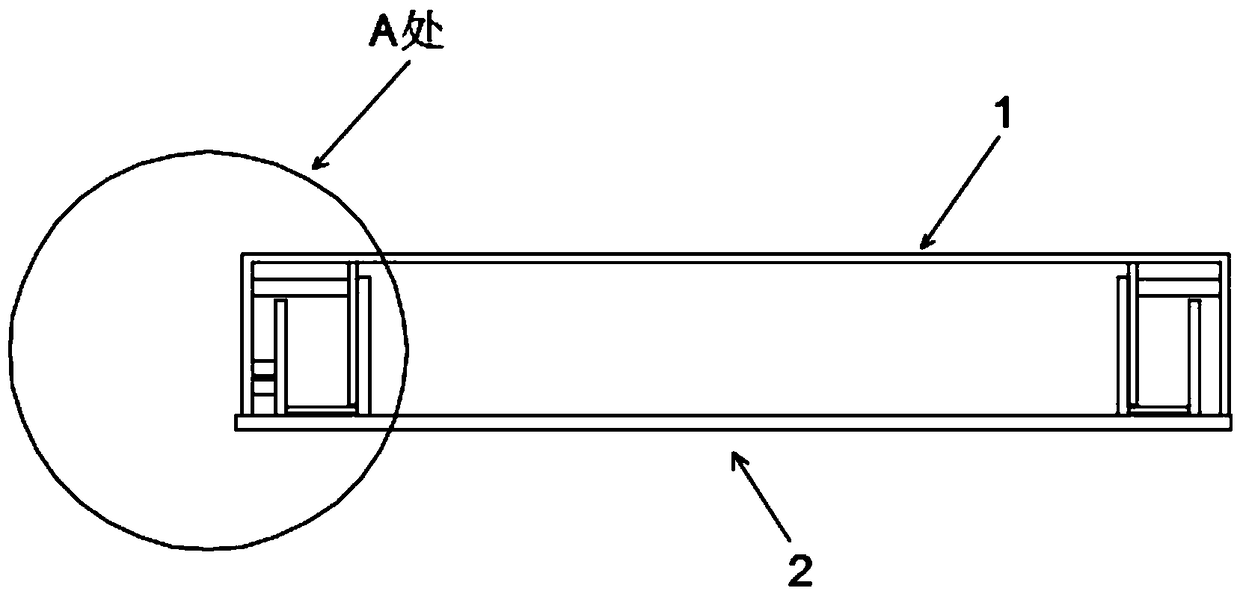

A new energy vehicle charging pile

ActiveCN113415189BAvoid clutterReduce the risk of injuryCharging stationsCleaning using toolsNew energyEngineering

The present invention relates to the technical field of new energy automobile accessories, in particular to a charging pile for new energy automobiles, which includes a charging pile main body, a display screen, a charging gun and a cable main body. The surface is provided with a retracting mechanism 1 and a retracting mechanism 2, and the two are distributed correspondingly up and down. A pneumatic component is arranged between the retracting mechanism 1 and the retracting mechanism 2, and charging guns are respectively installed on both sides of the main body of the charging pile. By adding retraction mechanism 1 and retraction mechanism 2 to the device, the cable body connected to the charging gun and the charging pile body can be retracted, shielded and protected, avoiding the disorderly arrangement of cables, and further reducing the impact on Cars or car owners who often charge may cause injury risks, such as the probability of tripping or electric shock accidents. The car charging pile has a simple structure and is easy to use, which can greatly improve the cleanliness of the charging operation area, while further avoiding risks and improving the charging operation. security.

Owner:苏州城投新能源发展有限公司

Cefixime dispersible tablet and preparation method thereof

ActiveCN103479587BReduce processReduce pollutionAntibacterial agentsOrganic active ingredientsHigh probabilityLactose

The invention discloses cefixime dispersible tablets. 1000 cefixime dispersible tablets are prepared from the following raw materials in parts by weight: 40-70 g of cefixime, 5-20 g of pregelatinized starch, 5-20 g of lactose, 5-10 g of low-substituted hydroxypropyl cellulose, 1-5 g of lubricant and a proper amount of polyvinylpyrrolidone. The invention also provides a preparation method of the cefixime dispersible tablets. According to the preparation method, granulation is performed by using a one-step granulation method; the three steps of mixing, granulation and drying of the conventional wet granulation are finished in a closed container at one time; according to the process, the problems that the solvent is remained and discolored in the wet granulation process and the pharmaceutical ingredients are heated to be lost in the drying process are avoided, and the problems such as serious dust flying and high probability of cross contamination during tabletting in the dry granulation process are also avoided.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Waste water treatment equipment for rubber and plastic processing

ActiveCN108327142BImprove adsorption capacityImprove adsorption efficiencyCoatingsWastewaterSuction equipment

The invention discloses high-precision rubber and plastic equipment technology equipment. The high-precision rubber and plastic equipment technology equipment comprises a floater, an impurity removalbox arranged on the top of the floater, and an impurity removal barrel arranged at the bottom of the floater. An up-down expanding through hole is formed in the floater. The impurity removal box is internally provided with a discharging cavity with a downward port, wherein the discharging cavity communicates with the through hole, the diameter of the discharging cavity is larger than that of the through hole, and a dirt throwing barrel is connected in the discharging cavity in a rotation fit manner. Water steaming equipment is arranged on the inner wall of the left end of the discharging cavity, air suction equipment is arranged on the inner wall of the right end of the discharging cavity, and storage cavities with upward ports are formed in the inner wall of the bottom of the dischargingcavity, wherein the storage cavities are located in the two ends of the through hole and are symmetric. The high-precision rubber and plastic equipment technology equipment is simple in structure andconvenient to operate, move and carry; and meanwhile the pollutant adsorption efficiency and effect are improved.

Owner:江苏胜悦科技有限公司

Production process of magnesium chloride granules

The invention provides a production process of magnesium chloride granules. The process comprises the following steps of: crushing crystallized magnesium chloride and then adding into a dissolving tank, stirring and then standing for precipitation, detecting that the baume degree of the liquid is not lower than 33.5Be, and preliminarily filtering the liquid in the dissolving tank to obtain preliminarily filtered liquid magnesium chloride; naturally precipitating the preliminarily filtered liquid magnesium chloride for at least three days, and then adding into two precise filters in turns for precise filtration to obtain liquid magnesium chloride; adding the liquid magnesium chloride into a preheater for preheating, and then entering a two-effect separator and a one-effect separator in turns for vapor-liquid separation to obtain solid magnesium chloride; and conveying the solid magnesium chloride to a dust-free granulating chamber through a pipe, and granulating by a granulator to obtain the finished magnesium chloride granules. The process has the characteristics that the process design is advanced, the operability is good, the process parameter is controllable, and the industrial production can be realized; the prepared product has high purity and can meet requirements of a high-grade product; the dissolution is fast in speed, the liquid is clear and transparent without impurities after the dissolution; and an automatic flow line is adopted, and the product is large in bulk density and unlikely to deliquesce.

Owner:LIANYUNGANG RIFENG CALCIUM & MAGNESIUM

Grafting method of flower plant salvia splendens

The invention discloses a grafting method of a flower plant salvia splendens. The method comprises the following steps: taking a salvia splendens plant at a seedling stage as a scion and grafting thescion on a salvia coccinea plant at the seedling stage. The grafting method of the flower plant salvia splendens, disclosed by the invention, is used for distant grafting of salvia plants; the growthvigor and resistance of the scion are improved by utilizing high-quality stocks and the distant hybridization affinity between a grafted seedling and a salvia coccinea interspecific plant is enhanced;the fructification rate of hybridization is improved.

Owner:BEIJING UNIV OF AGRI

Production process of magnesium chloride granules

ActiveCN103145159BAdvanced process designEasy to operateMagnesium chloridesProduction linePhysical chemistry

The invention discloses a production process of magnesium chloride granules. The production process comprises the following steps of: crushing crystallized magnesium chloride, then, placing the crushed magnesium chloride into a dissolving tank, stirring the crushed magnesium chloride, then, standing for settlement, inspecting the baume degree of the liquid not to be lower than 33.5Be', and primarily filtering the liquid in the dissolving tank to obtain primary filtrate magnesium chloride; naturally settling the primary filtrate magnesium chloride for at least three days, then, sequentially placing the primary filtrate magnesium chloride into a two-effect separator and a one-effect separator to carry out steam-liquid separation to obtain liquid magnesium chloride; and delivering the liquid magnesium chloride to a dust-free pelleting chamber through a pipeline to pellet to obtain finished products of the magnesium chloride granules. The method is advanced in process design, strong in operability, controllable in process parameter and capable of realizing large-scale industrial production; the prepared product is high in purity and capable of meeting the requirement of a high-quality product; the magnesium chloride granules are high in dissolving speed and clear, transparent and free of impurities after being dissolved; and an automatic production line is adopted, and the product is high in stacking density and not easy to air slake.

Owner:LIANYUNGANG RIFENG CALCIUM & MAGNESIUM

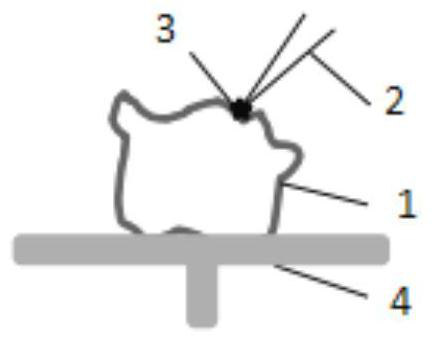

Potato container for culturing virus-free potato microtuber

InactiveCN108834907AFully contactedIncrease the bottom areaHorticulture methodsPlant tissue cultureEngineeringPolycarbonate

The invention relates to the field of a microbiological culture dish, and particularly relates to a potato container for culturing a virus-free potato microtuber. Polycarbonate of which light transmittance is 90% or more is used as a raw material and is subjected to one-time processing and extrusion molding to form two split bodies of an upper cover and a lower cover; the upper cover and the lowercover are matched for use; and the potato container is excellent in sealing performance, reusable and suitable for industrial tissue culture production of the virus-free potato microtuber. Anti-pollution sealing rings are specially designed at inner rings of the upper cover and the lower cover so as to effectively control pollution caused by exchange of internal and external air flows in the culturing process, ensure that a produced test tube seedling is thick and strong in growth and developed in root system, and provide powerful guarantee for growth of the microtuber.

Owner:黑龙江省农业科学院植物脱毒苗木研究所

A new type of odorless paint room

InactiveCN104249047BSmooth circulationLight lacquer smellLiquid surface applicatorsUsing liquid separation agentFiberLacquer

The invention belongs to the field of furniture processing, and particularly relates to a novel odorless pain room. The novel odorless pain room comprises a room formed by enclosure of walls and a roof, an indoor floor located in the room body, an air supply device arranged outside the room body and a deodorizing and sewage draining device arranged in the room body. A roof net rack is arranged under the roof, fiber cotton is laid on the roof net rack, an air supply chamber is formed between the filter cotton and the roof, the air supply device comprises a suction fan case, a suction opening arranged in the suction fan case and an air supply pipe, the deodorizing and sewage draining device comprises a drain tank and a pain leaking net rack set up on the drain tank, and a sewage draining exit is arranged in the wall. Sprayed floating paint and air with paint odor are downwardly blown to the drain tank through filtered natural air blowing down from the roof downwardly so as to be absorbed by water and discharged out of the paint room via the sewage draining exit. A water tank is further arranged at the sewage draining exit, water overflowing from the water tank forms a water curtain to filter air passing through the sewage draining exit, and accordingly paint and paint odor in air discharged from the paint room to the sewage draining exit are removed.

Owner:ZHEJIANG ANJI ANFENG FURNITURE

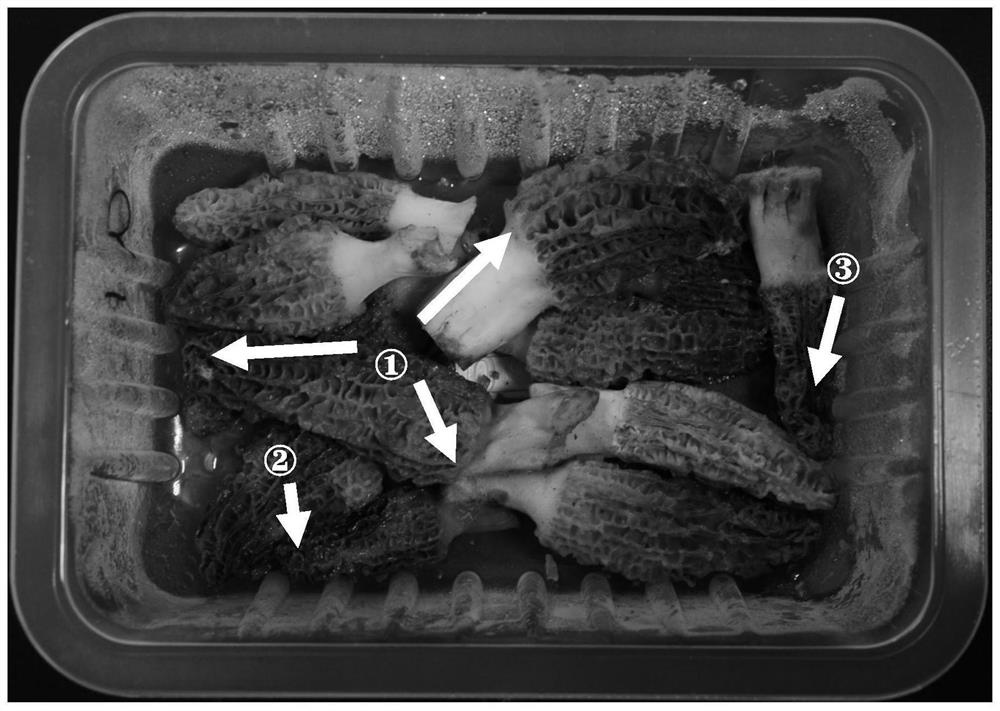

Composite preservation method for morchella esculenta by adopting low-temperature ozone drying agent

InactiveCN113100287AKeep the flavorAvoid damageFruit and vegetables preservationFood ingredientsDesiccantEnvironmental engineering

The invention relates to a composite preservation method for morchella esculenta by adopting a low-temperature ozone drying agent, which belongs to the field of preservation of morchella esculenta. The method comprises steps of carrying out pre-cooling treatment on the harvested morchella esculenta for 4-5 hours at the temperature of 3-5 DEG C, fumigating the precooled morchella esculenta in an ozone closed space with the concentration of 16 mg / m<3> to 19 mg / m<3> for 10 to 30 minutes, boxing the fumigated morchella esculenta and allochroic silicagel desiccant according to the weight ratio of (12-20): 1, and sealing a film and storing in an environment of 4 DEG C. The method has the advantages that under the condition that the appearance, smell and taste of the morchella esculenta are not affected, completeness and cleanness of morchella esculenta bodies are kept, cleaning, spraying and soaking of liquid are avoided, exogenous pollution is reduced, self enzyme activity is inhibited, and therefore the freshness degree of the morchella esculenta is kept, the preservation period is prolonged, and the method is a morchella esculenta fresh-keeping composite technology which is simple and convenient to operate and suitable for popularization.

Owner:GUIZHOU CROP VARIETIES RESOURCE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com