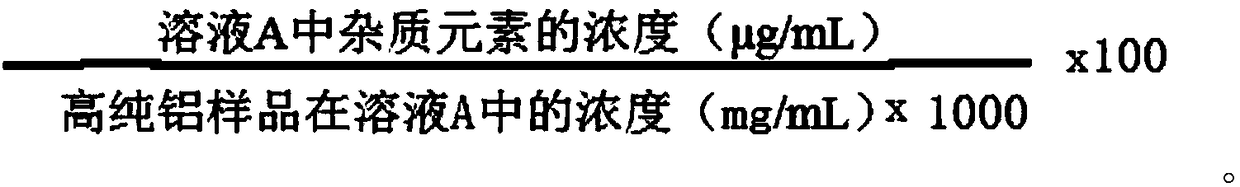

Method for determining impurity elements in high-purity aluminum through microwave digestion-inductive coupled plasma optical emission spectrometer

A technology of microwave digestion and plasma, which is applied in thermal excitation analysis, material excitation analysis, preparation of test samples, etc., can solve the problems of long time consumption and easy pollution of acid wet digestion, and achieve fast measurement speed and accuracy High, high detection authenticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Experimental steps:

[0049] 1. Clean the sample

[0050] Rinse with deionized water and dry for use.

[0051] 2. Sample dissolution

[0052]Weigh 5g of high-purity aluminum sample (accurate to ±0.0001g) into a 100mL polytetrafluoroethylene digestion tank, add 5mL of hydrochloric acid and 1mL of nitric acid, cover it and place it in a microwave digestion apparatus for digestion. After the digestion program (see Table 1) is finished, take it out, open the can after cooling down, dilute it in a 100mL volumetric flask with deionized water, and shake it well for testing. Make a blank along with the sample.

[0053] 3. Instrument operation

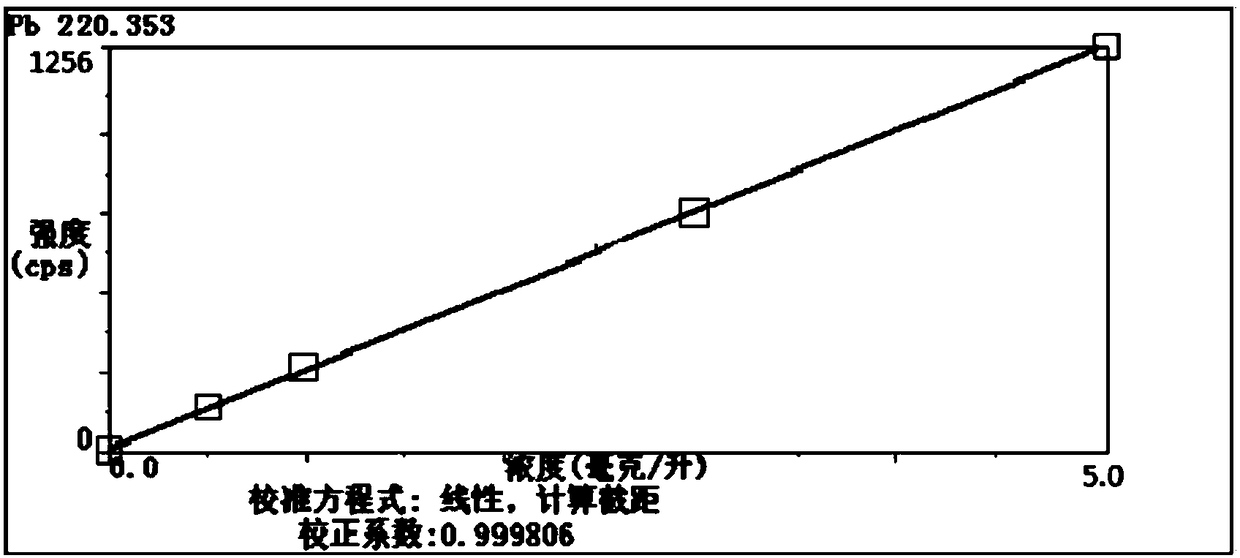

[0054] Open the analysis control software, preheat the instrument for half an hour, set the equipment power to 1.0Kw, the cooling air flow rate to 15L / min, the auxiliary air flow rate to 0.2L / min, the atomization pressure to 50psi (1psi=6.89kPa), and the sample lifting speed to 1.2 ml / min, click the "Plasma" button to form a stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com