Baked corn essence, a preparing method thereof and an application of the essence in cigarettes

A technology for roasting corn and essence, applied in the directions of preparing tobacco, application, essential oil/spice, etc., can solve problems such as unreported, and achieve the effects of less external pollution, low cost, and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

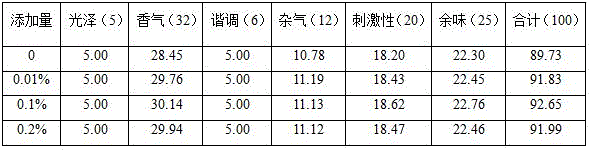

Image

Examples

Embodiment 1

[0026] A preparation method of roasted corn essence, specifically comprising the following steps:

[0027] 1) High-speed beating: mix corn kernels and water according to the mass ratio of 1:1.5, soak for 60 minutes, and break into pulp to obtain corn steep liquor;

[0028] 2) Enzyme hydrolysis: Add amylase (enzyme activity 20000U / g) accounting for 1.0% of the mass of corn steep liquor, and then enzymatically hydrolyze in a water bath at 50°C for 3 hours. Obtain enzymatic solution;

[0029] 3) Concentration under reduced pressure: Use a rotary evaporator to concentrate the enzymolysis solution under reduced pressure at a vacuum of 0.08MPa and 50°C to obtain a slurry;

[0030] 4) High-temperature baking: put the slurry into an oven, set the temperature at 100°C, heat for 8 hours, and cool to room temperature to obtain the roasted corn aroma product;

[0031] 5) Soxhlet extraction: Add the aroma product of roasted corn into a Soxhlet extractor, use 50% ethanol aqueous solution ...

Embodiment 2

[0039] A preparation method of roasted corn essence, specifically comprising the following steps:

[0040] 1) High-speed beating: mix corn kernels and water according to the mass ratio of 1:3, soak for 60 minutes, break into pulp to obtain corn steep liquor;

[0041] 2) Enzyme hydrolysis: add amylase (enzyme activity 20000U / g) accounting for 0.8% of the mass of corn steep liquor, and then enzymatically hydrolyze in a water bath at 60°C for 2 hours. Obtain enzymatic solution;

[0042] 3) Concentration under reduced pressure: Use a rotary evaporator to concentrate the enzymolysis solution under reduced pressure at a vacuum of 0.08MPa and 70°C to obtain a slurry;

[0043] 4) Baking at high temperature: put the slurry into an oven, set the temperature at 150°C, heat for 4 hours, and cool to room temperature to obtain the roasted corn aroma product;

[0044] 5) Soxhlet extraction: add the aroma product of roasted corn into a Soxhlet extractor, use 50v% ethanol aqueous solution as...

Embodiment 3

[0052] A preparation method of roasted corn essence, specifically comprising the following steps:

[0053] 1) High-speed beating: mix corn kernels and water according to the mass ratio of 1:2, soak for 40 minutes, break into pulp to obtain corn steep liquor;

[0054] 2) Enzyme hydrolysis: add amylase (enzyme activity 20000U / g) accounting for 1.5% of the mass of corn steep liquor, and then enzymatically hydrolyze in a water bath at 70°C for 1 hour. Obtain enzymatic solution;

[0055] 3) Concentration under reduced pressure: Use a rotary evaporator to concentrate the enzymolysis solution under reduced pressure at a vacuum of 0.06MPa and 70°C to obtain a slurry;

[0056]4) Baking at high temperature: Put the slurry into the oven, set the temperature at 180°C, heat for 2 hours, cool to room temperature to obtain the roasted corn aroma product;

[0057] 5) Soxhlet extraction: add the aroma product of roasted corn into a Soxhlet extractor, use 50v% ethanol aqueous solution as solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com