Waste water treatment equipment for rubber and plastic processing

A waste water treatment and equipment technology, applied in the direction of coating, etc., can solve the problems of ineffective removal of stains, long time for removing impurities, high cost, etc., and achieve the effect of saving adsorption raw materials, facilitating cyclic adsorption, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

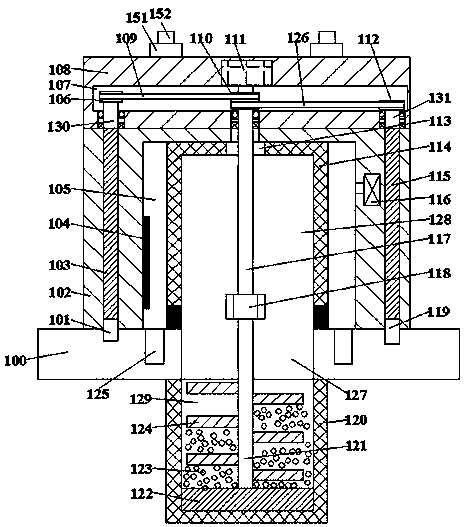

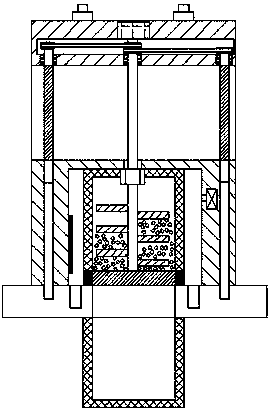

[0015] Such as figure 1 and image 3 As shown, a waste water treatment equipment for rubber and plastic processing of the present invention includes a floating body 100, an impurity removal tank 102 arranged on the top of the floating body 100, and an impurity removal cylinder 120 arranged at the bottom of the floating body 100. The floating body 100 is provided with a through hole 127 extending up and down, and the impurity removal box 102 is provided with a discharge chamber 105 with a port downward and communicating with the through hole 127. The diameter of the discharge chamber 105 is larger than that of the through hole 127. Diameter, said removal chamber 105 is rotated and connected with a dirt removal cylinder 114, the inner wall of the left end of said removal chamber 105 is provided with a water steaming device 104, and the inner wall of said removal chamber 105 is provided with an air suction device 116, said removal The inner wall of the bottom of the chamber 105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com