High-frequency manganese-zinc ferrite material

A manganese-zinc ferrite and high-frequency technology, which is applied in the field of manganese-zinc ferrite materials and their preparation, can solve the problems such as the inability to meet the design and matching requirements of high-frequency switching power supplies, and achieves a small change rate of power loss, stable performance, The effect of low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation of the high-frequency manganese-zinc ferrite material of the present invention sequentially includes the steps of mixing, pre-calcination, pulverization, granulation, pressing and sintering.

[0023] Use industrial grade or the same grade of commercial iron oxide, manganese oxide, zinc oxide powder as raw material, the specific surface area of raw material powder can be 3~30m 2 Appropriate selection within the range of / g. The main components are mixed evenly according to the required ratio, and then pre-sintered. The pre-sintering temperature can be between 800~1100℃, and the time is 0~4 hours. The crushed particle size of the calcined powder is controlled between 0.5 and 1.8 μm, and the particle size distribution is concentrated and has a good normal distribution. The pulverized slurry is granulated by a pressure spray drying tower, and the characteristics are adjusted according to the pressing requirements. The sintering is carried out in an atmo...

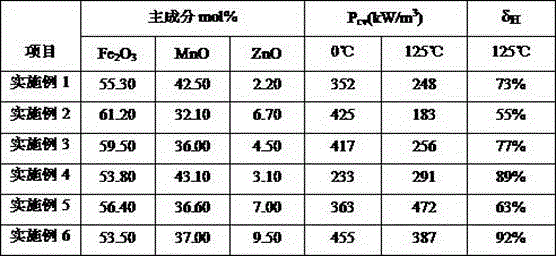

Embodiment 1

[0028] Iron oxide, manganese oxide, and zinc oxide powders were used as raw materials and weighed according to the composition shown in Table 1. The annular MnZn ferrite core was prepared according to the following preparation conditions.

[0029] The main components are mixed evenly according to the required ratio, and then pre-sintered. The pre-sintering temperature can be 1000°C for 3 hours. The weighed impurity, that is, the auxiliary component (CaCO 3 , V 2 o 5 , SnO 2 The contents are respectively 0.05wt%, 0.05wt%, 0.5wt% in terms of main components) mixed with the calcined powder evenly, and then put into a sand mill for crushing. The crushed particle size is controlled between 0.5 and 1.8 μm, and the particle size distribution is concentrated and has a good normal distribution. The pulverized slurry is granulated by a pressure spray drying tower, and the characteristics are adjusted according to the pressing requirements. The sintering is carried out in an atmosph...

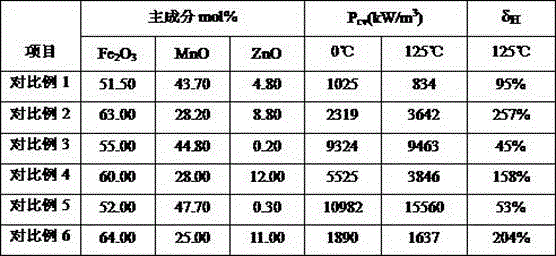

Embodiment 2~6

[0033] As shown in Table 1, except Fe as the main component 2 o 3 The composition is in the range of 53mol%~62mol% and the composition of ZnO is changed in the range of 0.5mol%~10mol%, and the rest is manganese oxide. The remaining processes are carried out in the same manner as in Example 1, and the main components are uniformly mixed according to the required ratio, and then pre-sintered. The pre-sintering temperature can be 1000°C for 3 hours. The weighed impurity, that is, the auxiliary component (CaCO 3 , V 2 o 5 , SnO 2 The contents are respectively 0.05wt%, 0.05wt%, 0.5wt% in terms of main components) mixed with the calcined powder evenly, and then put into a sand mill for crushing. The crushed particle size is controlled between 0.5 and 1.8 μm, and the particle size distribution is concentrated and has a good normal distribution. The pulverized slurry is granulated by a pressure spray drying tower, and the characteristics are adjusted according to the pressing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power loss | aaaaa | aaaaa |

| Power loss | aaaaa | aaaaa |

| Power loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com