Layered high-entropy double-boron carbide ceramic powder and preparation method thereof

A technology of borocarbide and ceramic powder, which is applied in the field of layered high-entropy double boron carbide ceramic powder and its preparation, can solve the problems of high price and unsuitability of metal single substance powder, and achieve low preparation cost and control Reaction process, effect of easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In a specific embodiment, the preparation method comprises the steps of:

[0023] (1) Take at least three metal oxides, boron source and carbon source in proportion;

[0024] (2) adding solvent and ball milling medium, ball milling mixed raw materials, vacuum drying and sieving to obtain uniformly mixed powder;

[0025] (3) hydraulically compact the uniformly mixed powder, and then obtain a densified green body through cold isostatic pressing;

[0026] (4) Sintering the green body under normal pressure and high temperature under vacuum or protective atmosphere to obtain a layered high-entropy double boron carbide block material;

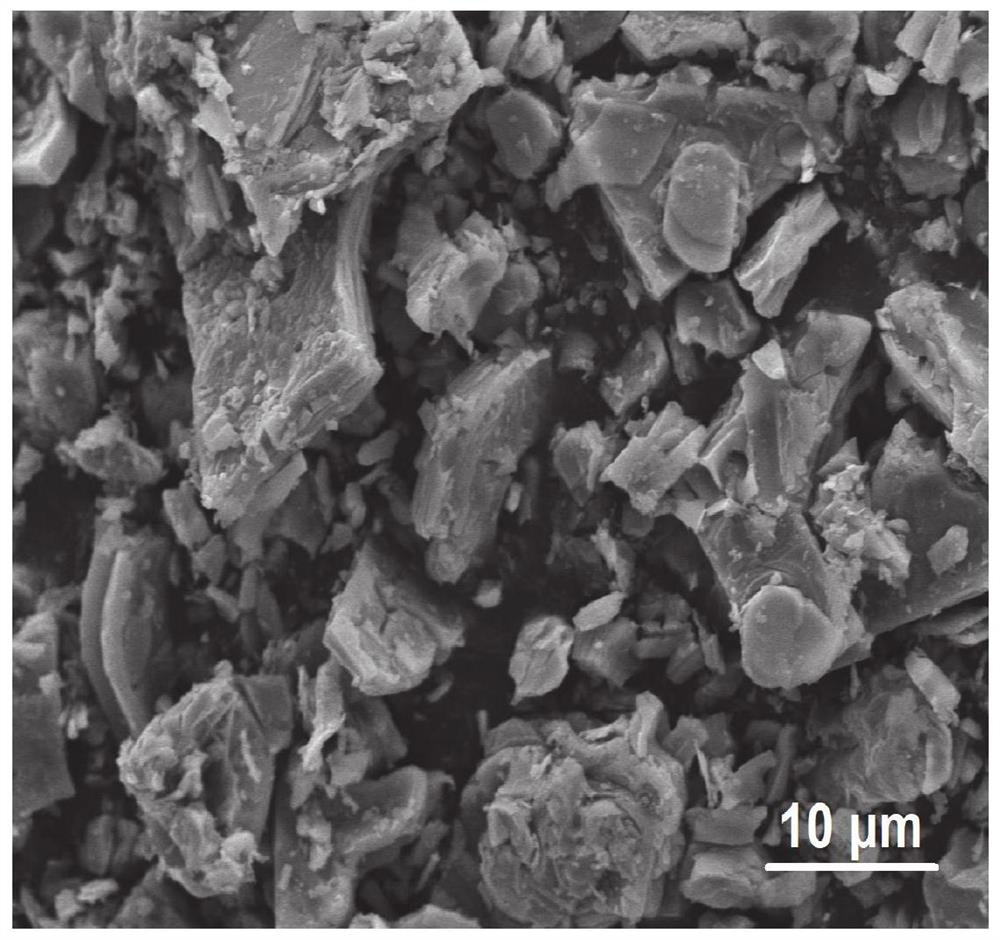

[0027] (5) Crushing and grinding the bulk material after high-temperature sintering to finally obtain a layered high-entropy double boron carbide ceramic powder.

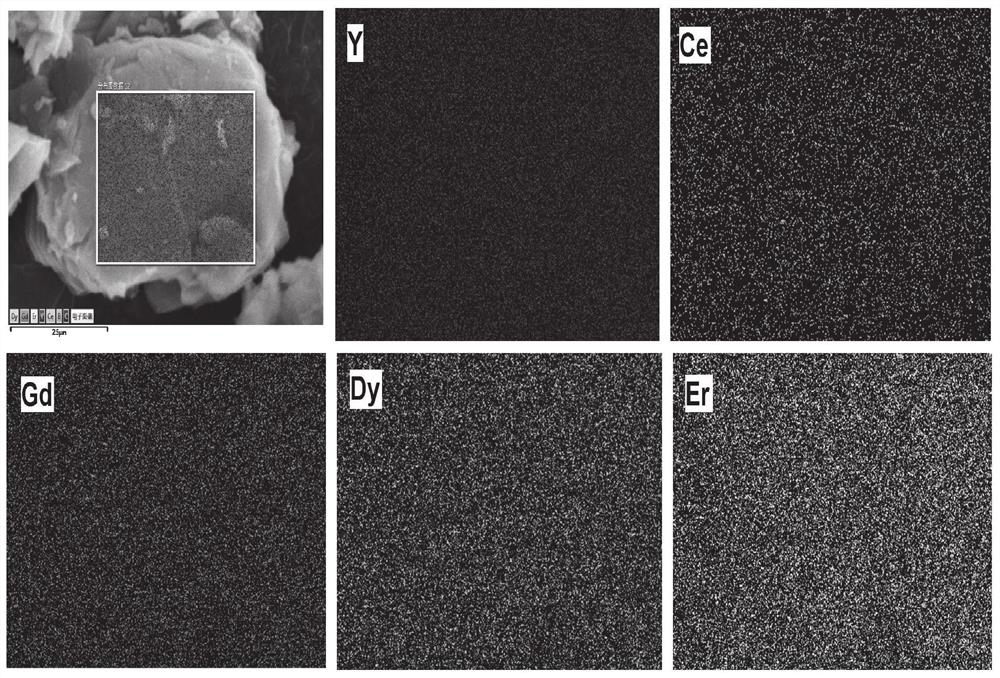

[0028] Preferably, the metal oxide is selected from yttrium oxide (Y 2 o 3 ), cerium oxide (CeO 2 ), gadolinium oxide (Gd 2 o 3 ), dysprosium oxide (Dy 2 o 3 ), erbium oxid...

Embodiment 1

[0042] (1) put Y 2 o 3 , CeO 2 、Gd 2 o 3 、Dy 2 o 3 、Er 2 o 3 , BN and carbon black are compounded in a molar ratio of 1:2:1:1:1:20:36;

[0043] (2) Mix the proportioned powder in absolute ethanol, place it in a planetary ball mill for ball milling (the speed of the ball mill is 300r / min, and the ball milling time is 24h), and the powder after ball milling is vacuum-dried at 80°C Pass through a 200-mesh sieve to obtain a uniformly mixed powder;

[0044] (3) Put the uniformly mixed powder in a stainless steel mold, and press it with hydraulic pressure (holding pressure is 15MPa, holding time is 5min), and then further formed by cold isostatic pressing (holding pressure is 220MPa, holding time is 5min). Time is 15min), obtain green body;

[0045] (4) Place the green body in a graphite crucible, then place the graphite crucible in a multifunctional sintering furnace, raise the temperature to 2000°C at 10°C / min under an argon atmosphere, keep it warm for 2h, and let it cool...

Embodiment 2

[0049] (1) put Y 2 o 3 , CeO 2 、Gd 2 o 3 、Dy 2 o 3 、Er 2 o 3 , B 4 C and carbon black are prepared in a molar ratio of 1:2:1:1:1:5:31;

[0050] (2) Mix the proportioned powder in absolute ethanol, place it in a planetary ball mill for ball milling (the speed of the ball mill is 350r / min, and the ball milling time is 24h), and the powder after ball milling is vacuum-dried at 80°C Pass through a 200-mesh sieve to obtain a uniformly mixed powder;

[0051] (3) Put the uniformly mixed powder in a stainless steel mold, press it with hydraulic pressure (holding pressure is 12MPa, holding time is 10min), and then further form it by cold isostatic pressing (holding pressure is 220MPa, holding time is 10min). time is 10 min) to obtain the green body;

[0052] (4) Place the green body in a graphite crucible, then place the graphite crucible in a multifunctional sintering furnace, raise the temperature to 1950°C at 10°C / min under an argon atmosphere, keep it warm for 3h, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com