Composite bone cement and preparation method thereof

A bone cement and composite technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve problems that have not been reported, and achieve the effects of improving injection performance, increasing osteoinductivity, and improving injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The calcium sulfate salt is calcium sulfate dihydrate, the calcium phosphate salt is tricalcium phosphate, and the additive is polyethylene glycol. The method is as follows:

[0025] (1) Weigh 90% calcium sulfate dihydrate (99%) and tricalcium phosphate (1%) according to the mass percentage, supplemented with polyethylene glycol, and mix them evenly in a ball mill. The polyethylene glycol accounts for the total mass. 10%;

[0026] (2) Take it out and dry and grind in an oven at 70°C, then transfer the crystal in an autoclave at a temperature of 135°C and a pressure of 0.2MPa, and the reaction time is 8h;

[0027] (3) After the reaction, it is placed in an oven at 100°C for drying for 12 hours and ground evenly to obtain bone cement powder;

[0028] (4) Weigh 5 g of bone cement powder, add the powder to water according to a powder-to-liquid mass ratio of 3:1, stir evenly, and solidify to obtain bone cement.

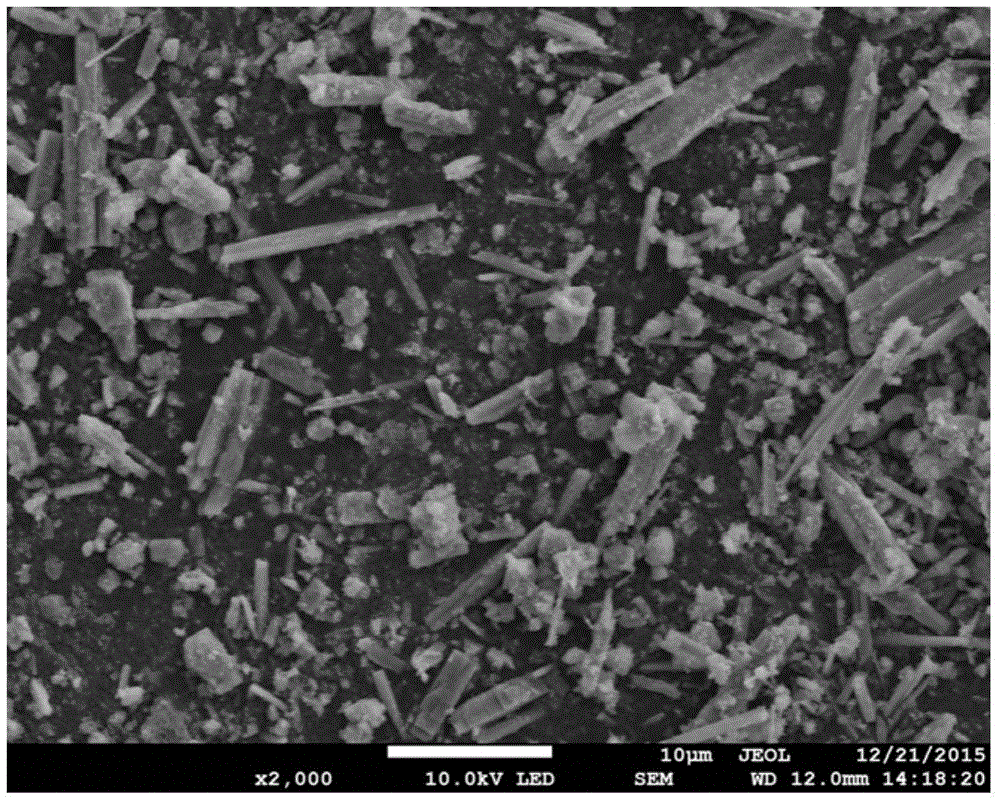

[0029] Observe the microscopic appearance of the prepared bone cement p...

Embodiment 2

[0032] The calcium sulfate salt is calcium sulfate dihydrate, the calcium phosphate salt is composed of tricalcium phosphate and strontium hydroxyapatite, and the additive is polyethylene glycol. The method is as follows:

[0033] (1) Weigh 95% calcium sulfate dihydrate (65%), tricalcium phosphate, and strontium hydroxyapatite (35%) according to mass percentage, supplemented with polyethylene glycol, and mix them evenly in a ball mill. Diol accounts for 5% of the total mass;

[0034] (2) Take it out and dry and grind in an oven at 70°C, then transfer the crystal in an autoclave with a temperature of 120°C and a pressure of 0.1MPa, and the reaction time is 8h;

[0035] (3) After the reaction, put it in an oven at 80°C for 12 hours to dry, and grind evenly to obtain bone cement powder;

[0036] (4) Weigh 5 g of bone cement powder, add the powder to water according to the powder-to-liquid mass ratio of 1:1, stir evenly, and solidify to obtain bone cement.

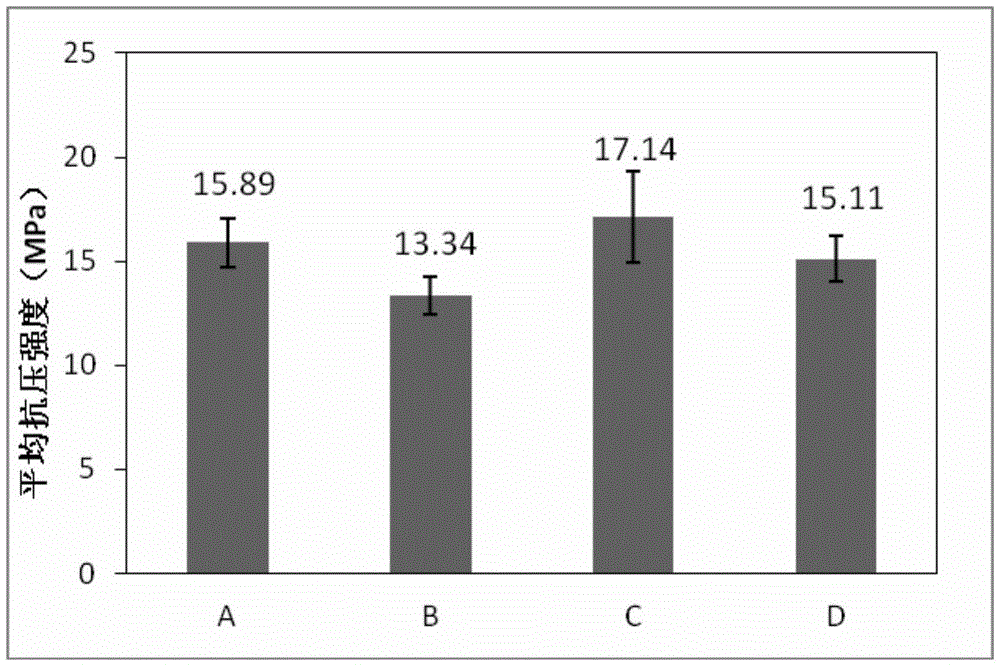

[0037] Place the bone cement in...

Embodiment 3

[0039] The calcium sulfate salt is calcium sulfate dihydrate, the calcium phosphate salt is hydroxyapatite, and the additive is polyethylene glycol. The method is as follows:

[0040] (1) Weigh 99% calcium sulfate dihydrate (90%) and hydroxyapatite (10%) according to the mass percentage, supplemented with polyethylene glycol, and mix them evenly in a ball mill. The polyethylene glycol accounts for the total mass. 1%;

[0041] (2) Take it out and dry and grind in an oven at 70°C, then transfer the crystal in an autoclave at a temperature of 145°C and a pressure of 0.26MPa, and the reaction time is 5h;

[0042] (3) After the reaction, put it into an oven at 90°C for 12 hours to dry, and grind evenly to obtain bone cement powder;

[0043] (4) Weigh 5 g of bone cement powder, add the powder to water according to a powder-to-liquid mass ratio of 2.5:1, stir evenly, and solidify to obtain bone cement.

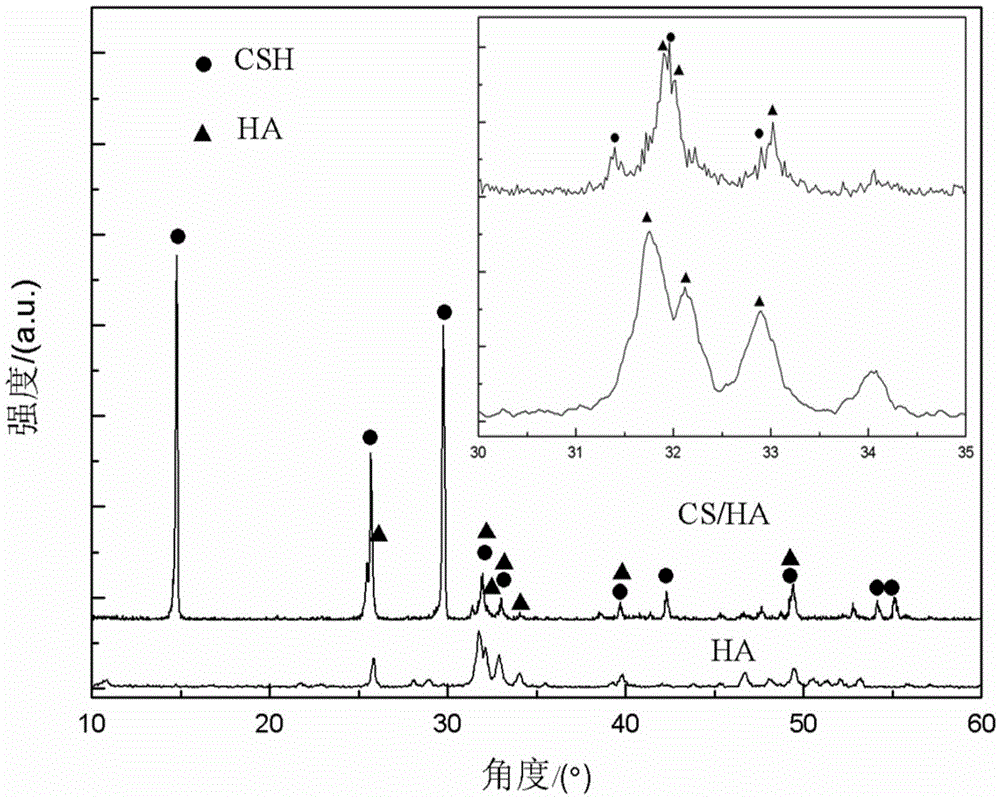

[0044] The prepared bone cement powder was characterized by XRD and compared with the dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com