Preparation method of nanocrystal lithium-rich single-phase Li-Si compound block material

A technology of bulk materials and compounds, which is applied in the field of preparation of nanocrystalline lithium-rich single-phase Li-Si compound bulk materials, can solve the problems of unreported preparation method and limited preparation technology of nano-structured Li-Si alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

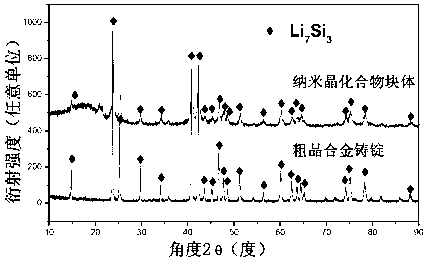

Embodiment 1

[0023] (1) With nanocrystalline single-phase Li 7 Si 3The compound bulk material is the final target material. According to the atomic ratio of 2.3:1 (x=2.3), the corresponding mass of Li flakes and Si powder was weighed, and an additional Li flake weighing 3% of the mass of Li flakes was added to compensate for the loss of Li during the preparation process. Using a mold made of cemented carbide as a container, put a small amount of Si powder into the mold to cover the bottom surface of the mold in an argon-filled glove box (ambient oxygen content 7 Si 3 alloy ingots.

[0024] (2) In a glove box filled with argon gas, Li 7 Si 3 The alloy ingot was crushed into powder, and put into a ball mill jar according to the ball mass ratio of 60:1, the ball milling speed was 500r / min, and the ball milling time was 16 hours to obtain amorphous Li x Si alloy powder.

[0025] (3) In an argon-filled glove box, the amorphous Li 7 Si 3 The alloy powder is put into a cemented carbide mo...

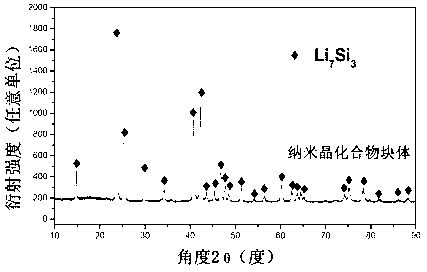

Embodiment 2

[0028] (1) With nanocrystalline single-phase Li 7 Si 3 The compound bulk material is the final target material. According to the atomic ratio of 2.3:1 (x=2.3), the corresponding mass of Li flakes and Si powder were weighed, and Li flakes weighing 4% of the mass of Li flakes were additionally added to compensate for the loss of Li during the preparation process. Using a mold made of cemented carbide as a container, put a small amount of Si powder into the mold to cover the bottom surface of the mold in an argon-filled glove box (ambient oxygen content 7 Si 3 alloy ingots.

[0029] (2) In a glove box filled with argon gas, Li 7 Si 3 The alloy ingot was crushed into powder, and put into a ball mill jar according to the mass ratio of ball to material of 60:1, the ball mill speed was 700r / min, and the ball mill time was 12 hours to obtain Li 7 Si 3 alloy powder.

[0030] (3) In an argon-filled glove box, the amorphous Li 7 Si 3 The alloy powder is loaded into a cemented ca...

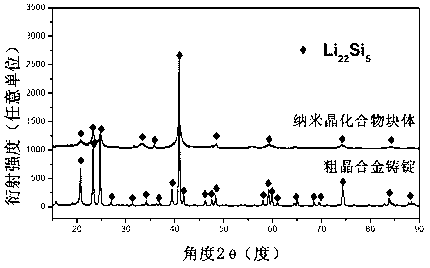

Embodiment 3

[0033] (1) With nanocrystalline single-phase Li 13 Si 4 The compound bulk material is the final target material. According to the atomic ratio of 3.3:1 (x=3.3), the corresponding mass of Li flakes and Si powders were weighed, and Li flakes weighing 4% of the Li flake mass were additionally added to compensate for the loss of Li during the preparation process. Using a mold made of cemented carbide as a container, put a small amount of Si powder into the mold to cover the bottom surface of the mold in an argon-filled glove box (ambient oxygen content 13 Si 4 alloy ingots.

[0034] (2) In a glove box filled with argon gas, Li 13 Si 4 The alloy ingot was crushed into powder, and put into a ball mill jar according to the ball mass ratio of 60:1, the ball milling speed was 500r / min, and the ball milling time was 16 hours to obtain amorphous Li 13 Si 4 alloy powder.

[0035] (3) In an argon-filled glove box, the amorphous Li 13 Si 4 The alloy powder is put into a cemented ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com