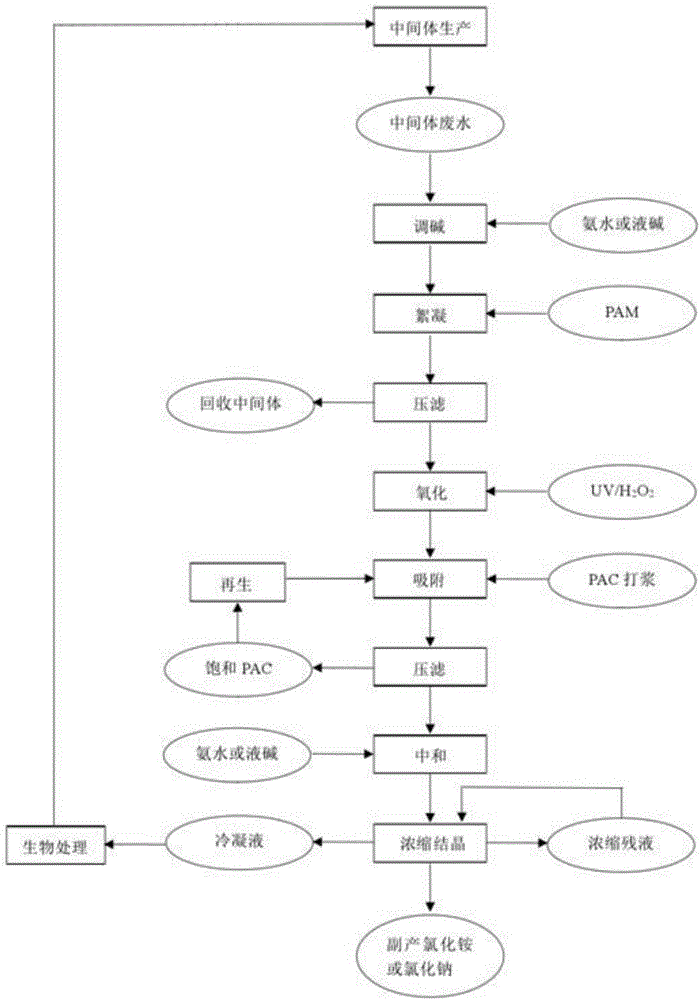

Recycling treatment method for anilines intermediate production wastewater

A technology for the production of waste water and treatment methods, which is applied in the direction of neutralization water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve problems such as difficult removal of high-salt components in waste water, expensive resin, and difficult recovery of analytical solution , to achieve the effect of mild conditions, reduced dosage, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Collect respectively the mother liquor water (that is, cyanoethylaniline and benzyl chloride react to produce waste water containing sodium chloride under the action of soda ash) and washing water for the production of N-cyanoethyl-N-benzylaniline, wherein the washing water Back to the production of intermediates. The mass percent content of sodium chloride in the mother liquor water is 15%, the COD is 17400 mg / L, and the chromaticity is 1800 times.

[0054] The mother liquid water enters the flocculation tank, and the waste lye produced in industrial production is added to adjust the pH to 7-8. Under the condition of stirring, polyacrylamide aqueous solution is continuously added. The mass fraction of polyacrylamide aqueous solution is 0.2%, and the dosage is 0.1% by mass, after continuous stirring for 15 minutes, settle naturally for 1 hour, press filter, and recover the intermediate to obtain the precipitate I and the treatment solution I respectively.

[0055] ...

Embodiment 2

[0065] (1) Collect respectively the mother liquor water (that is, cyanoethylaniline and benzyl chloride react to produce waste water containing ammonium chloride under the action of ammonia) and washing water for the production of N-cyanoethyl-N-benzylaniline, wherein the washing water Back to the production of intermediates. The mass percent content of ammonium chloride in the mother liquor water is 18%, the COD is 16200 mg / L, and the chromaticity is 1700 times.

[0066] The mother liquid water enters the flocculation tank, and the waste lye produced in industrial production is added to adjust the pH to 7-8. Under the condition of stirring, polyacrylamide aqueous solution is continuously added. The mass fraction of polyacrylamide aqueous solution is 0.2%, and the dosage is 0.1% by mass, after continuous stirring for 15 minutes, settle naturally for 1 hour, press filter, and recover the intermediate to obtain the precipitate I and the treatment solution I respectively.

[006...

Embodiment 3

[0077] (1) collect respectively the mother liquor water (that is 2-amino-4-acetamidoanisole and allyl chloride under the action of ammonia water) of producing N, N-diallyl-2-methoxy-5-acetamidoaniline The reaction produces waste water containing ammonium chloride) and washing water, wherein the washing water is reused for the production of intermediates. The mass percent content of ammonium chloride in the mother liquor water is 12%, the COD is 10960 mg / L, and the chromaticity is 1500 times.

[0078] The mother liquid water enters the flocculation tank, and the waste lye produced in industrial production is added to adjust the pH to 7-8. Under the condition of stirring, polyacrylamide aqueous solution is continuously added. The mass fraction of polyacrylamide aqueous solution is 0.2%, and the dosage is 0.1% by mass, after continuous stirring for 15 minutes, settle naturally for 1 hour, press filter, and recover the intermediate to obtain the precipitate I and the treatment sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com