Photo-anode composite membrane material and application thereof

A technology of photoanode and composite film, which is applied in electrolytic inorganic material coating, metal material coating process, nanotechnology for materials and surface science, etc. Unable to produce photogenerated electrons and other problems, to achieve the effect of improving cathodic protection effect, improving cathodic protection effect, and excellent anti-corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

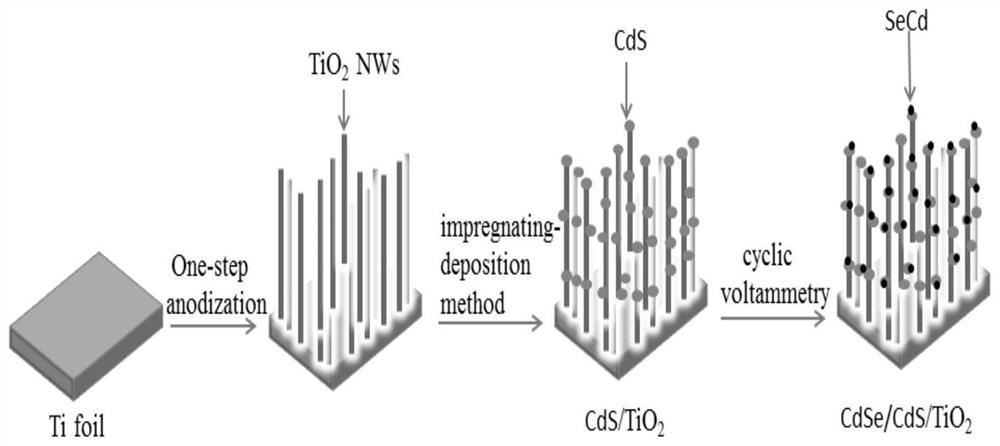

[0043] CdSe / CdS / TiO 2 Preparation of nanocomposite film photoanode materials (refer to figure 1 ), including the following steps:

[0044] Pretreatment of the titanium substrate: firstly, a titanium sheet with a purity of 99.9% and a thickness of 0.1 mm was cut into a size of 30 mm × 10 mm, and then each surface was polished 100 times with 2500 mesh sandpaper to serve as the growth substrate of the composite film; secondly, the Acetone, absolute ethanol and distilled water were used to ultrasonically clean the sample in turn, the cleaning time was 10min, 10min, 30min respectively, and then dried for later use; again, the titanium sheet was placed in a mixed solution at 85°C (the volume ratio was NaOH:Na 2 CO 3 :H 2 O=5:2:100) immersed in 90min, take out and clean with distilled water; finally, in HF solution (volume ratio is HF:H 2 (O=1:5) was etched for 1 min, and after taking it out, it was washed with acetone, absolute ethanol and distilled water in sequence, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com