Method for synthesizing fluorescent nano particles of rare earth chlorides by microwave aqueous phase

A rare earth fluoride, fluorescent nanotechnology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of large particle size of reaction products, reduced reaction efficiency, long-term grinding, etc., and is easy to master and control. The effect of reaction conditions, high purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

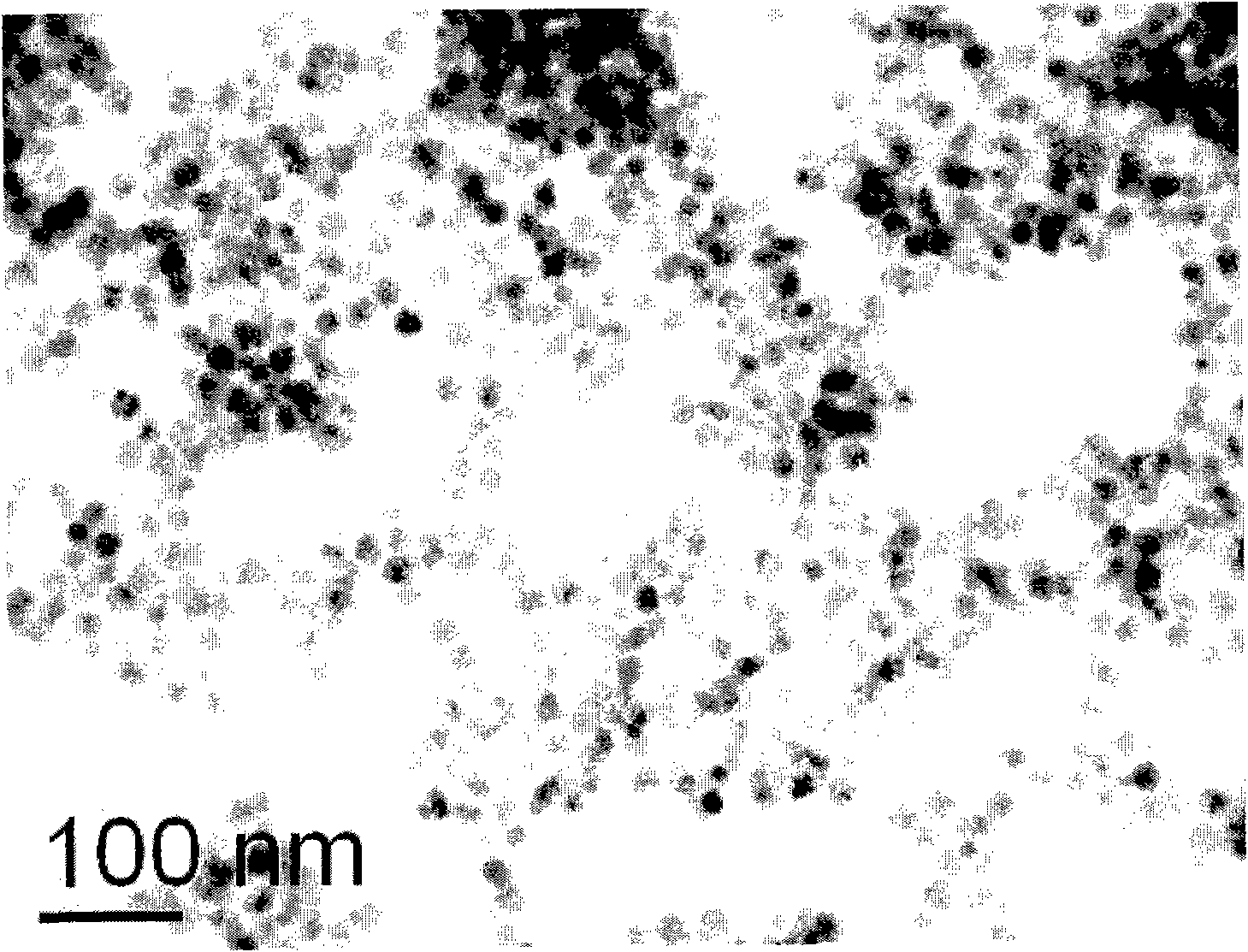

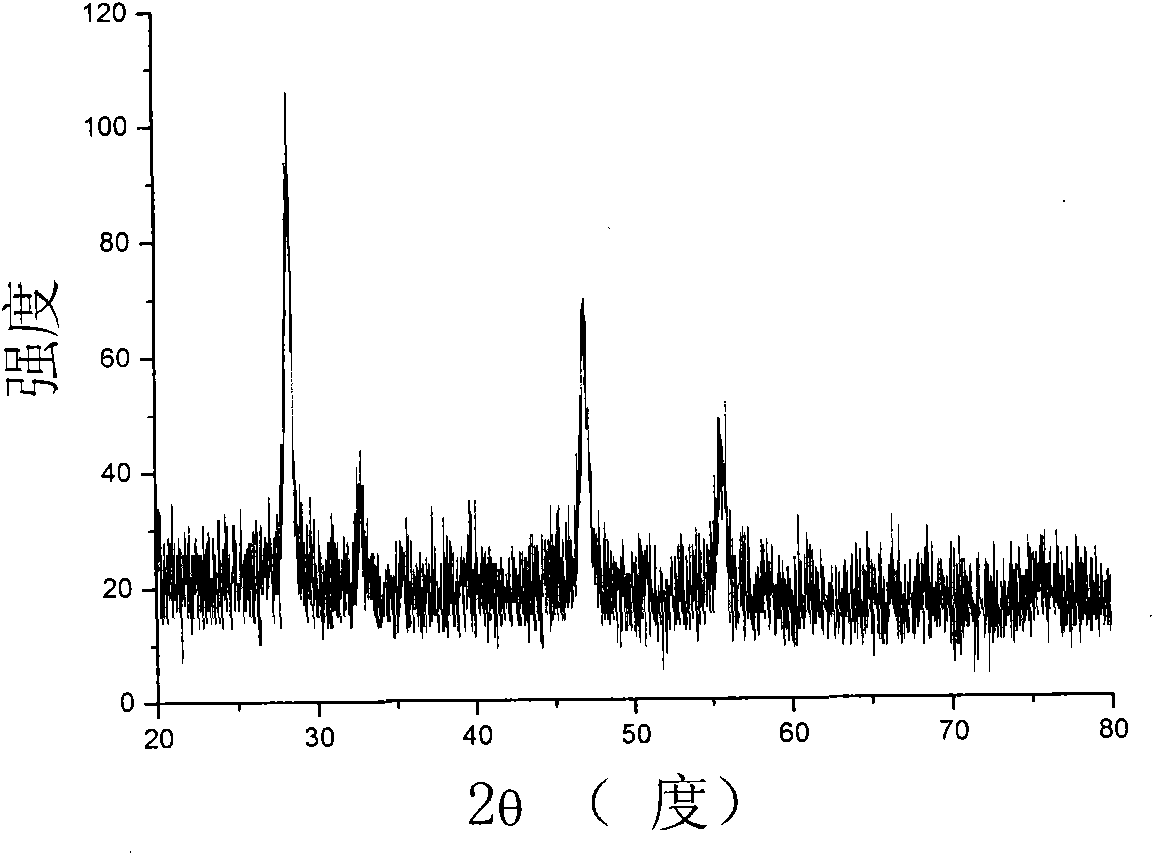

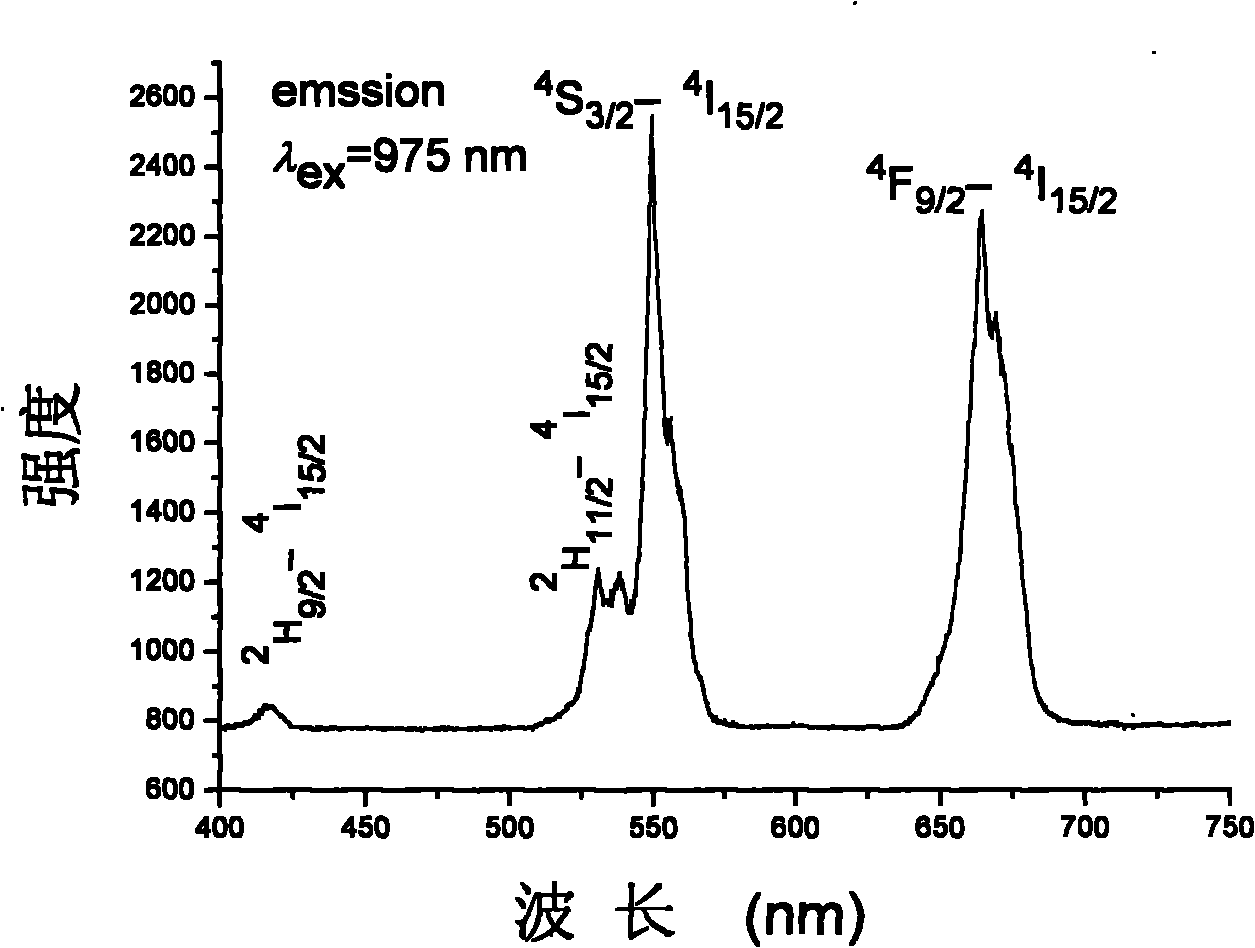

[0024] (1) Yttrium chloride, ytterbium chloride, erbium chloride, sodium chloride, ammonium fluoride and surfactant polyethyleneimine are dissolved in ethylene glycol respectively, and the concentration of rare earth chloride is 0.5mol / L, The concentration of sodium chloride is 0.2mol / L, the concentration of ammonium fluoride is 1.6mol / L, and the volume ratio of the mass of polyethyleneimine to the solvent is 1g: 20mL;

[0025] (2) Mix 9mL ethylene glycol, 5mL polyethyleneimine solution, 2.5mL sodium chloride solution, 0.7mL yttrium chloride solution, 0.2mL ytterbium chloride solution, 0.1mL erbium chloride solution and 2.5mL ammonium fluoride solution After adding it into the reaction vessel and stirring for 20 minutes, it was heated under reflux with a microwave at 600W, and the temperature was controlled at 180°C for 20 minutes, then it was left to cool to room temperature, and then centrifuged to separate the nanomaterials;

[0026] (3) Wash the nanomaterials separated in ...

Embodiment 2

[0029] (1) Lanthanum chloride, cerium chloride, terbium chloride, ammonium fluoride and surfactant polyethyleneimine are dissolved in deionized water respectively, the concentration of rare earth chloride is 0.5mol / L, and the concentration of ammonium fluoride is 1.6mol / L, the volume ratio of the mass of polyethyleneimine to the solvent is 1g: 20mL;

[0030] (2) 13mL water, 5mL polyethyleneimine solution, 0.85mL lanthanum chloride solution, 0.1mL cerium chloride solution, 0.05mL terbium chloride solution and 1mL ammonium fluoride solution were added to the reaction vessel and stirred for 10 minutes, It was heated under reflux with microwave 600W and magnetically stirred, and reacted at 90°C for 20 minutes, then allowed to stand and cooled to room temperature, and then centrifuged to separate nanomaterials;

[0031] (3) Wash the nanomaterials separated in the previous step with absolute ethanol or deionized water to remove unreacted ions therein, and then vacuum-dry them to obt...

Embodiment 3

[0034] (1) Calcium chloride, cerium chloride, terbium chloride, sodium chloride, ammonium fluoride and surfactant polyethyleneimine are dissolved in ethylene glycol respectively, and the concentrations of rare earth chloride and sodium chloride are both 0.5mol / L, the concentration of ammonium fluoride is 1.6mol / L, and the volume ratio of the mass of polyethyleneimine to the solvent is 1g: 20mL;

[0035] (2) Mix 10.5mL ethylene glycol, 5mL polyethyleneimine solution, 1mL sodium chloride solution, 0.85mL sodium chloride solution, 0.1mL cerium chloride solution, 0.05mL terbium chloride solution and 2.5mL ammonium fluoride solution After adding it into the reaction vessel and stirring for 20 minutes, heat it under reflux with a microwave at 600W and nitrogen gas, control the temperature at 180°C for 20 minutes, then let it stand to cool to room temperature, and then centrifuge to separate the nanomaterials;

[0036] (3) Wash the nanomaterials separated by centrifugation in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com