Method for positioning transversely-growing zinc oxide nanowires on silicon electrode

A zinc oxide nanowire, lateral growth technology, applied in chemical instruments and methods, crystal growth, nanotechnology and other directions, can solve problems such as growing nanowires, and achieve the effect of process saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

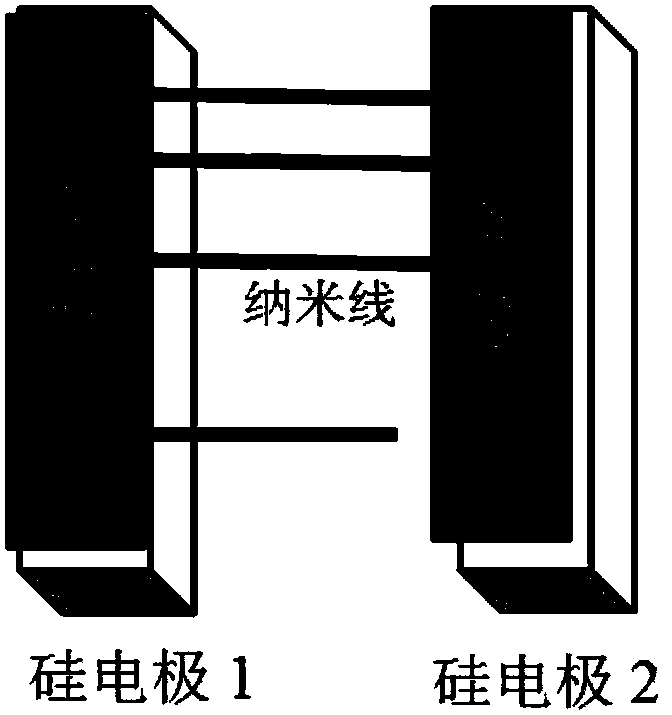

[0032] figure 2 It is a schematic diagram of the method for positioning and laterally growing zinc oxide nanowires on silicon electrodes in this embodiment.

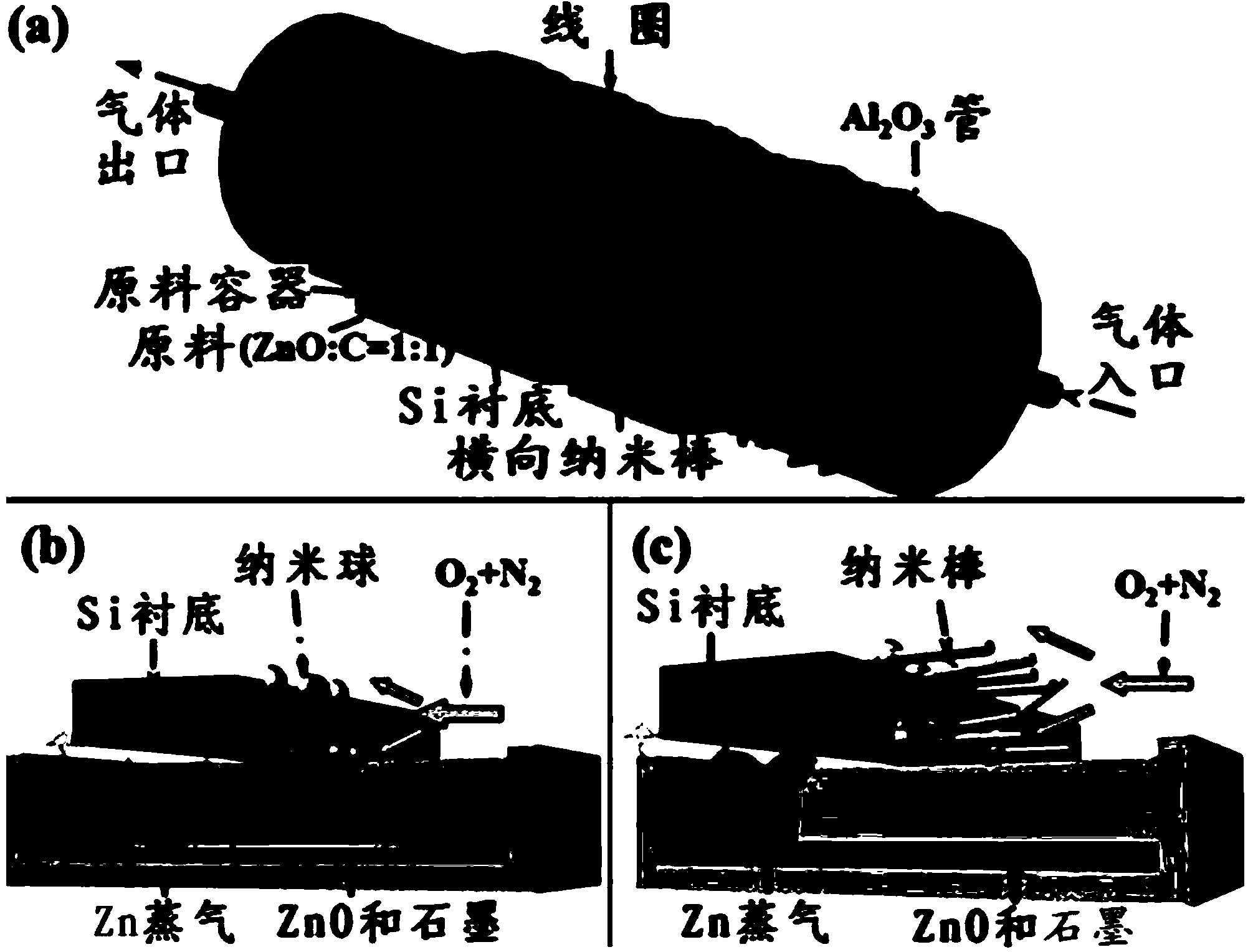

[0033] In this embodiment chemical vapor deposition adopts such as figure 2 High temperature tube vacuum furnace shown in a, including Al 2 o 3 pipe and a boat-shaped raw material container located within the pipe; said Al 2 o 3 One end of the tube is provided with a gas inlet, the other end is provided with a gas outlet, and the pipe body is provided with electric coils for heating or heat preservation; the bottom of the boat-shaped raw material container is equipped with raw materials, and the top is placed with a downward facing surface without a metal-coated catalyst film. silicon substrate.

[0034] When using, first of all Al 2 o 3 The tube is evacuated and the Al is then heated with an electric coil 2 o 3 Tube to 950-970 ℃ and keep warm, the raw materials react in the high temperature environment, and f...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the growth surface of the silicon electrode used in this embodiment is etched with micrometer electrodes.

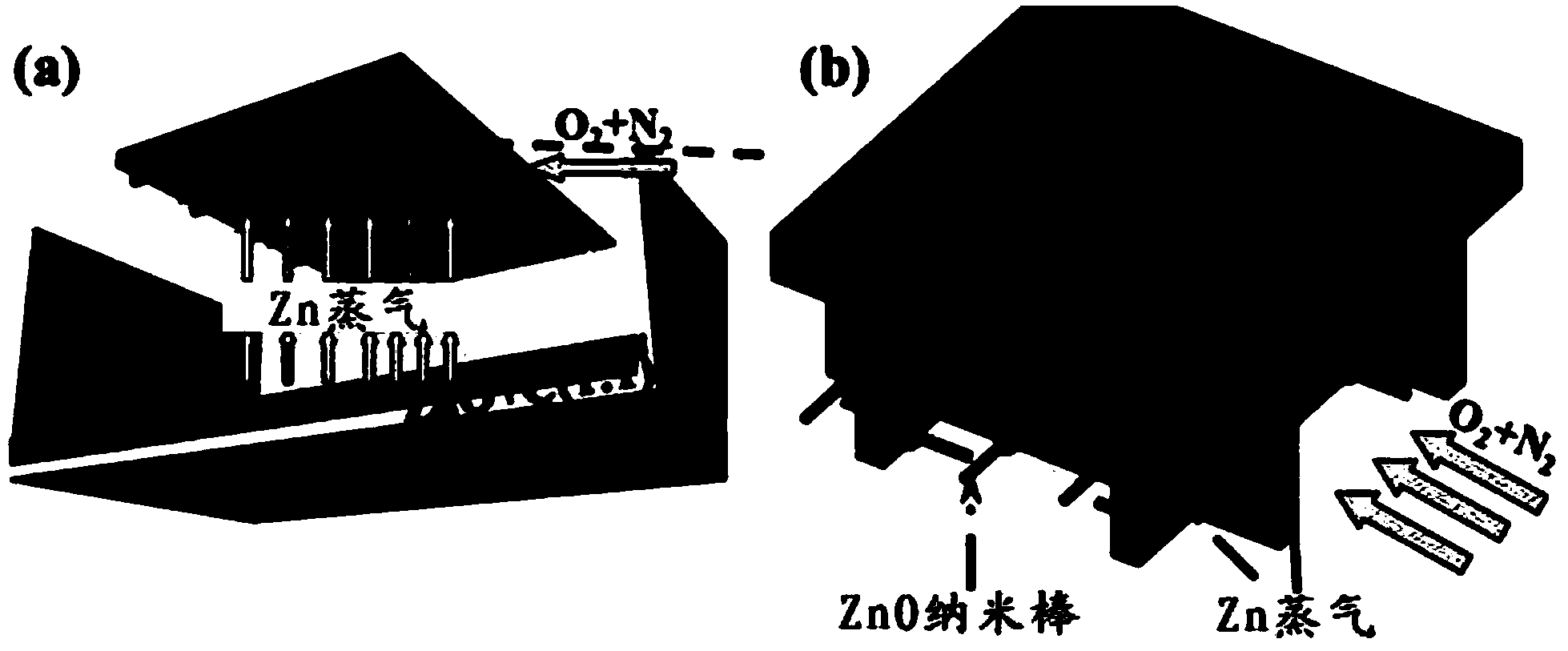

[0048] image 3 a is a schematic diagram of the growth process of zinc oxide nanowires in this embodiment, image 3 b for image 3 The enlarged view of the boat-shaped raw material container, silicon electrode substrate and nanowire in a, the difference between the nanowire growth process of this embodiment and Example 1 is that the silicon electrode used in this embodiment is etched with micron electrodes, and there are micrometer electrodes on the growth surface. There are many edges, and Zn vapor gathers on each edge and reacts with oxygen to crystallize and form zinc oxide nanodots; these zinc oxide nanodots grow preferentially along the direction perpendicular to the corners in the growth plane, forming lateral zinc oxide nanowires .

[0049] Figure 4 It is a scanning electron microscope ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com