Smelting process of Cr-Mn series spring steel

A technology of spring steel and cr-mn, which is applied in the field of metallurgy, can solve the problems of high rate of non-metallic inclusions exceeding the standard, unsatisfactory control of molten steel purity, unreasonable production technology, etc. source, eliminating the pretreatment process of molten iron, and reducing the effect of non-metallic inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

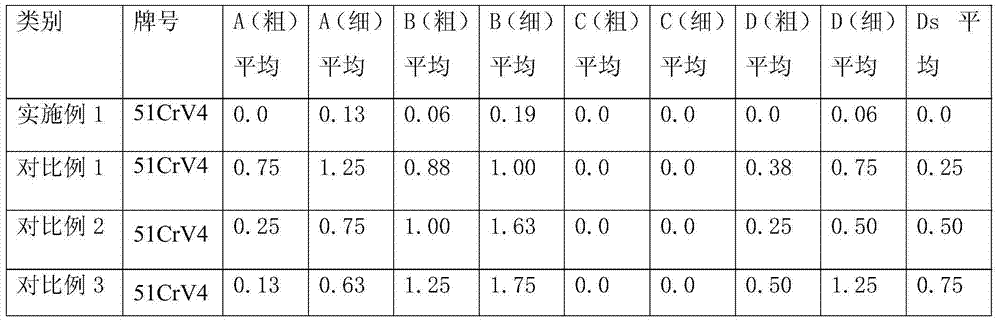

Examples

Embodiment 1

[0027] Take the production of Cr-Mn series spring steel 51CrV4 as an example:

[0028] Steelmaking process: molten iron (60-70%) + high-quality steel scrap (30-40%) - 100 tons of eccentric bottom electric furnace (EBT) - 100 tons of LF refining furnace - VD furnace - continuous casting machine (5 machines and 5 strands).

[0029] Electric furnace smelting process

[0030] 1. The new furnace lining and the first 3 furnaces of the new ladle shall not smelt this type of steel, and the baking of the ladle shall be strengthened before tapping to ensure the red hot state of the inner lining of the ladle.

[0031] 2. 60-70% of the low-sulfur molten iron and 30-40% of the company's self-produced high-quality steel scrap are used as the steel material for electric furnace smelting.

[0032] 3. The carbon content at the end point of the electric furnace is controlled above 0.15%, and the tapping temperature of the electric furnace is controlled at 1640-1660°C. The EBT electric furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com