Efficient composite fire extinguishing agent and preparation method thereof

A kind of fire extinguishing agent and high-efficiency technology, applied in the direction of fire prevention equipment, etc., can solve the problems of danger, failure to solve heptafluoropropane, loss of consciousness, etc., reduce the harm of human body and environment, improve the potential value of greenhouse effect and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

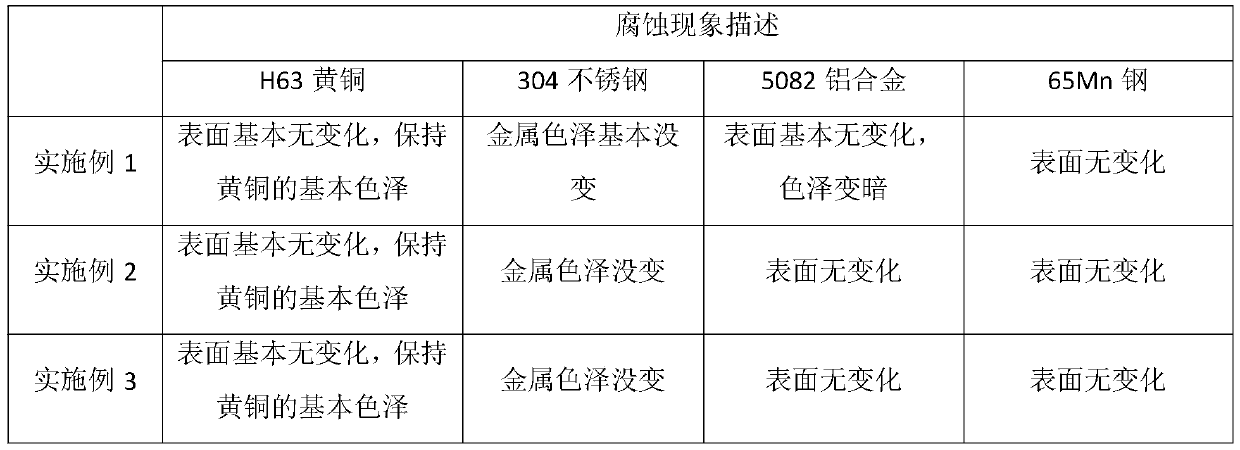

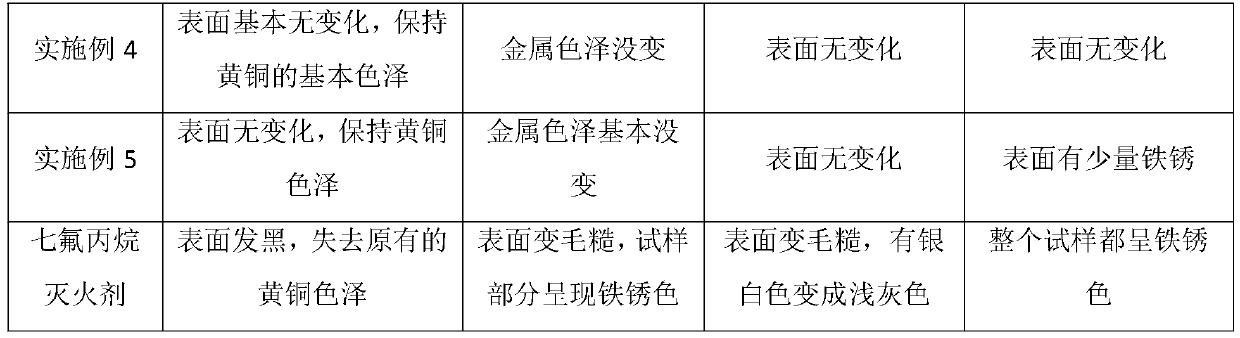

Examples

Embodiment 1

[0043] The fire extinguishing agent in this embodiment is made of the raw materials of following weight: 28kg of heptafluoropropane, 40kg of 1,1,2,2,3,3,4-heptafluorocyclopentane, 8kg of liquid nitrogen, 12kg of ammonium bicarbonate, calcium carbonate 5kg, potassium sulfate 3kg, talcum powder 6kg, diatomaceous earth 5kg.

[0044] The preparation method is as follows:

[0045] (1) Take the raw materials of the above weight;

[0046] (2) Grind ammonium bicarbonate, calcium carbonate, potassium sulfate, talcum powder, and diatomaceous earth into fine powder respectively, and sieve to obtain ammonium bicarbonate with a particle size of 3-5 μm and carbonic acid with a particle size of 0.3-0.6 mm. Calcium, potassium sulfate with a particle size of 0.1-0.5 mm, talcum powder with a particle size of 0.3-0.5 mm, diatomite with a particle size of 0.3-0.5 mm;

[0047] (3) Mix talcum powder, diatomaceous earth and calcium carbonate uniformly; Mix ammonium bicarbonate and potassium sulfat...

Embodiment 2

[0051] The fire extinguishing agent in this embodiment is made of the raw materials of following weight: 30kg of heptafluoropropane, 42kg of 1,1,2,2,3,3,4-heptafluorocyclopentane, 7kg of liquid nitrogen, 10kg of ammonium bicarbonate, calcium carbonate 4kg, potassium sulfate 2.5kg, talcum powder 5kg, diatomaceous earth 4kg.

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] The fire extinguishing agent in this embodiment is made of the raw materials of following weight: 32kg of heptafluoropropane, 44kg of 1,1,2,2,3,3,4-heptafluorocyclopentane, 6kg of liquid nitrogen, 9kg of ammonium bicarbonate, calcium carbonate 3kg, potassium sulfate 2kg, talcum powder 4kg, diatomaceous earth 3kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com