Three-phase traveling wave electric curtain dust removing system and construction method thereof

A technology of electric curtain dust removal and construction method, which is applied in chemical instruments and methods, cleaning methods and appliances, photovoltaic power generation, etc., and can solve the problems of poor dust removal effect and low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

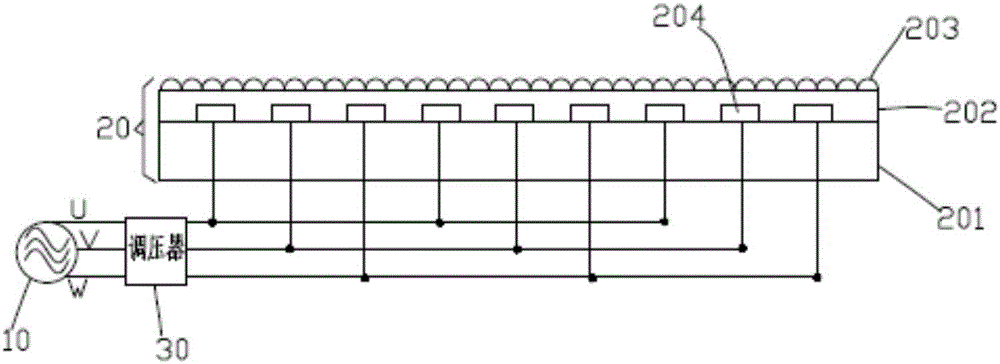

[0074] refer to figure 1 , a three-phase traveling wave electric curtain dust removal system, comprising a three-phase AC power supply 10 and an electric curtain 20; the electric curtain 20 is composed of an insulating substrate 201 and a plurality of groups of electrodes 204 evenly distributed on the surface of the substrate, the Described electrode 204 is rectangular parallelepiped, and each electrode 204 is parallel to each other, and the width of electrode 204 is equal to the spacing between two adjacent electrodes 204; With every adjacent three electrodes 204 constitute a moving cycle, in the moving cycle The three electrodes 204 are respectively connected to the U-phase line, the V-phase line and the W-phase line of the three-phase AC power supply 10 .

[0075] In another embodiment, the distance between two adjacent electrodes 204 is 0.1 mm-0.5 mm. This distance can ensure that the dust can form a continuous movement in the traveling wave electric field formed by the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com