Regeneration system and method for positive plate of lithium-ion battery

A lithium-ion battery and regeneration system technology, applied in the field of lithium-ion battery positive plate regeneration system, can solve the problems of low efficiency, complicated process, secondary pollution, etc., and achieve the effects of high recovery efficiency, environmentally friendly process, and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

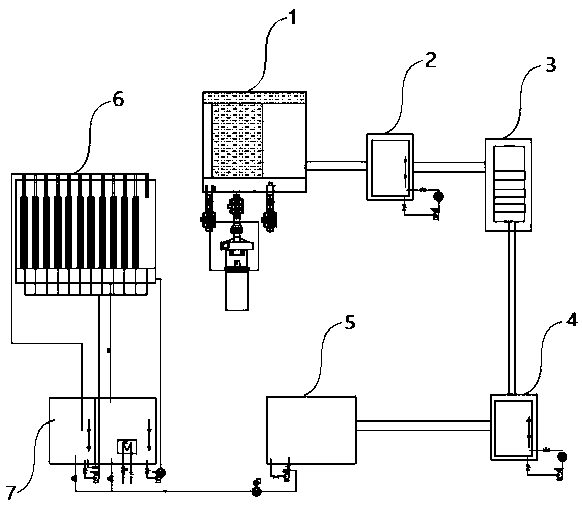

[0032] see figure 1 As shown, a lithium-ion battery positive plate regeneration system is composed of a blade crusher 1, an aluminum separation tank 2, a reduction roasting section 3, a lithium separation tank 4, an acid-dissolving tank 5, an electrolytic tank 6 and an electrolytic temporary storage tank 7 ;

[0033] The blade crusher 1 is connected to the aluminum separation tank 2, and the aluminum separation tank 2 is equipped with a solvent A for soaking the positive plate material of the lithium-ion battery for ultrasonic treatment; the aluminum separation tank 2 is connected to the reduction roasting Section 3 is connected; the reduction roasting section 3 is connected with the lithium separation tank 4, and the lithium separation tank 4 is filled with hot water and continuously fed CO 2 The lithium separation tank 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com