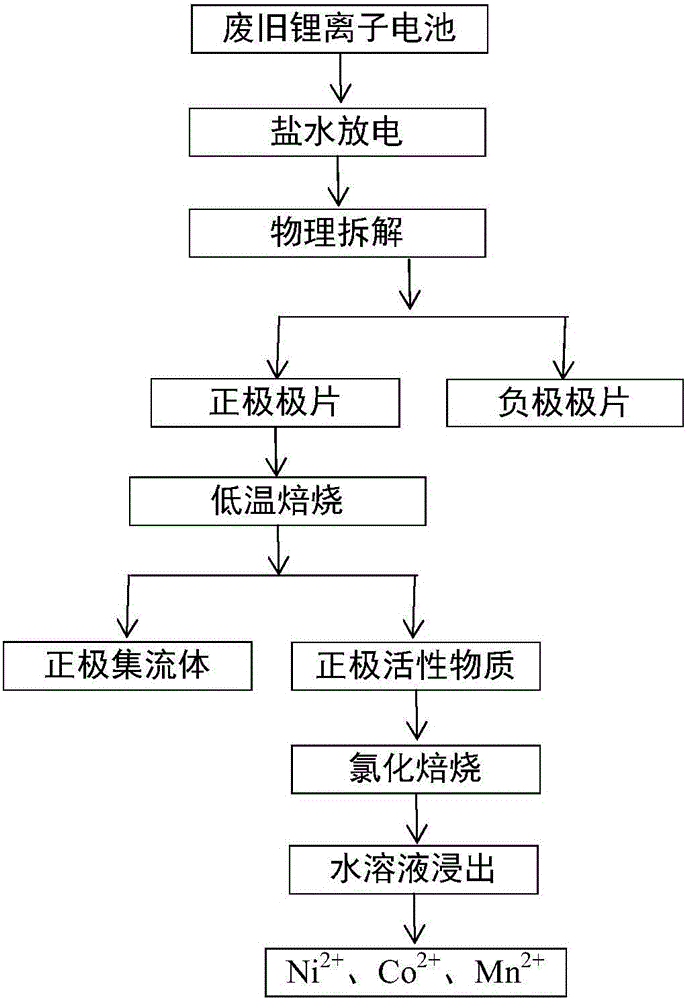

Method for recovering valuable metals from cathode materials of waste lithium ion batteries

A technology for lithium ion batteries and positive electrode materials, which is applied in the fields of efficient recovery of valuable metals and waste battery recycling and treatment, to avoid the consumption of inorganic acids and alkalis, efficient recovery, and large recovery benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take waste nickel-cobalt-manganese ternary lithium-ion batteries as an example. Lab-assembled scrap LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The ternary lithium-ion battery is placed in salt water and discharged for 5 hours, then physically disassembled, the battery cell is taken out, and the positive electrode piece is separated. The positive electrode piece was baked at 400° C. for 2 hours in a muffle furnace, the positive electrode current collector was recovered, and the positive electrode active material was collected. Take 1000g of the collected positive electrode active material and weigh 1200g of ammonium chloride, mix the two evenly, place them in a muffle furnace at 400°C, and chlorinate and roast for 25min. Finally, the obtained calcined sand is poured into a sufficient amount of aqueous solution, and leached for 30 minutes at room temperature. Ni in solution was tested by ICP 2+ 、Co 2+ , Mn 2+ Concentration, get Ni 2+ 、Co 2+ , Mn 2+ The leaching rates were 85.2...

Embodiment 2

[0025] The acquisition of the positive electrode active material is as described in Example 1. Take 1000g of the collected positive electrode active material and weigh 1000g of ammonium chloride, mix them evenly, place them in a muffle furnace at 400°C, and chlorinate and roast for 30min. Finally, the obtained calcined sand is poured into a sufficient amount of aqueous solution, and leached for 30 minutes at room temperature. Ni in solution was tested by ICP 2+ 、Co 2+ , Mn 2+ Concentration, get Ni 2+ 、Co 2+ , Mn 2+ The leaching rates were 84.3%, 78.1%, and 99.1%, respectively.

Embodiment 3

[0027] The acquisition of the positive electrode active material is as described in Example 1. Take 1000g of the collected positive electrode active material and weigh 2000g of ammonium chloride, mix the two evenly, place them in a muffle furnace at 400°C, and chlorinate and roast for 30min. Finally, the obtained calcined sand is poured into a sufficient amount of aqueous solution, and leached for 30 minutes at room temperature. Ni in solution was tested by ICP 2+ 、Co 2+ , Mn 2+ Concentration, get Ni 2+ 、Co 2+ , Mn 2+ The leaching rates were 88.4%, 85.3%, and 99.7%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com