Method for recycling and processing nickel in stainless steel pickling waste acid

A technology for pickling waste acid, recovery and treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of short equipment life, difficult environment maintenance, and air pollutant discharge and other issues to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

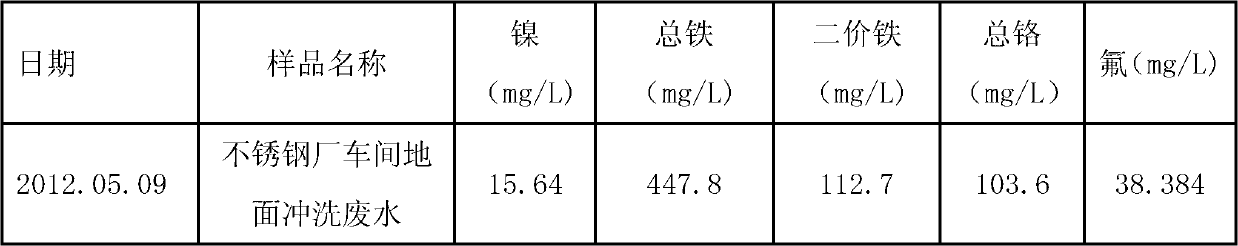

[0028] The water quality of mixed waste acid in a stainless steel plant is as follows:

[0029] Table 1 Stainless steel pickling mixed waste acid influent water quality

[0030]

[0031]

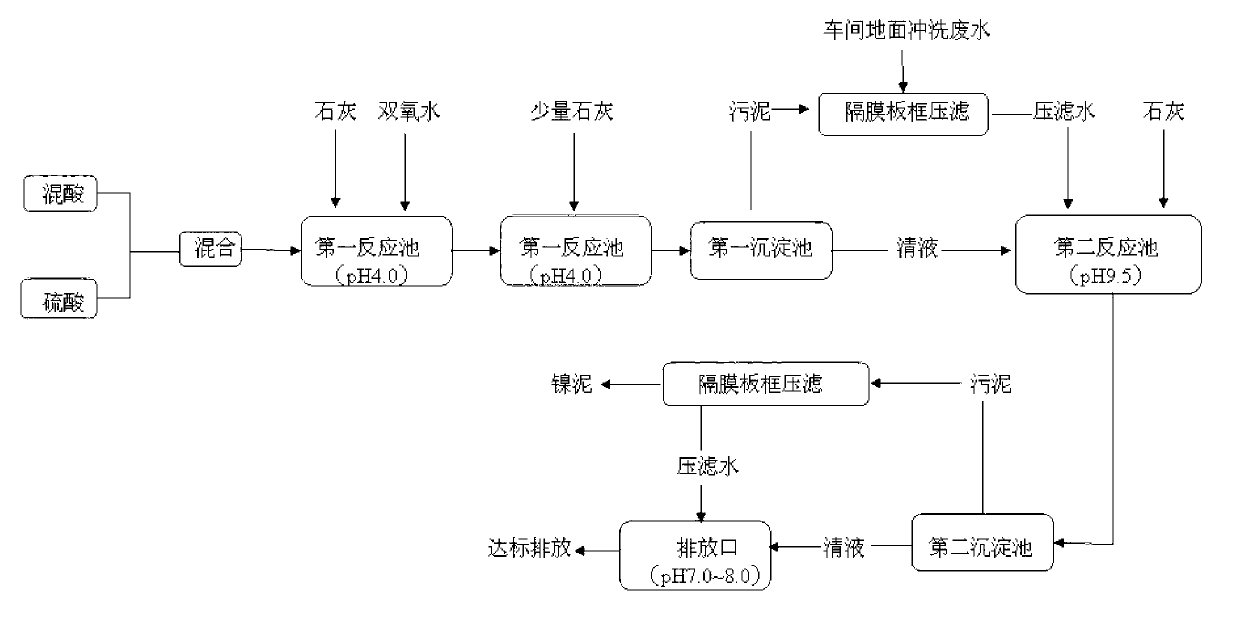

[0032] see figure 1 , a method for recycling nickel in stainless steel pickling waste acid, comprising the following steps:

[0033] a. The above sulfuric acid and mixed acid are mixed and injected into the first reaction tank (the ratio of sulfuric acid and mixed acid is about 1:1), and 16.7% (mass fraction) of lime is added through PLC (automatic dosing system) to adjust the pH value to 4.0 , carry out a sufficient reaction, in order to make the reaction sufficient, on-line monitoring of pH is carried out. In this step, the pH can be adjusted to 3.5~4.5.

[0034] b. After the above reaction is completed, add 27.5% (mass fraction) hydrogen peroxide according to 1% (volume ratio) of influent water, and react for 0.8 hours. Through this step, some ions that are difficult to remove a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com