Comprehensive zinc hydrometallurgy recovery system technique

A technology of hydrometallurgy and recovery system, which is applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc. It can solve the problems of high production cost, low economic benefit, and poor recycling of waste water, etc., to achieve clean The production environment is friendly and the effect of extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

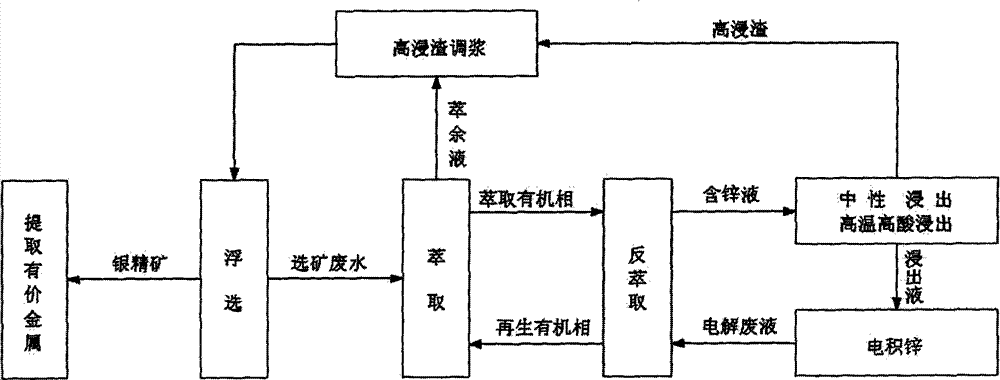

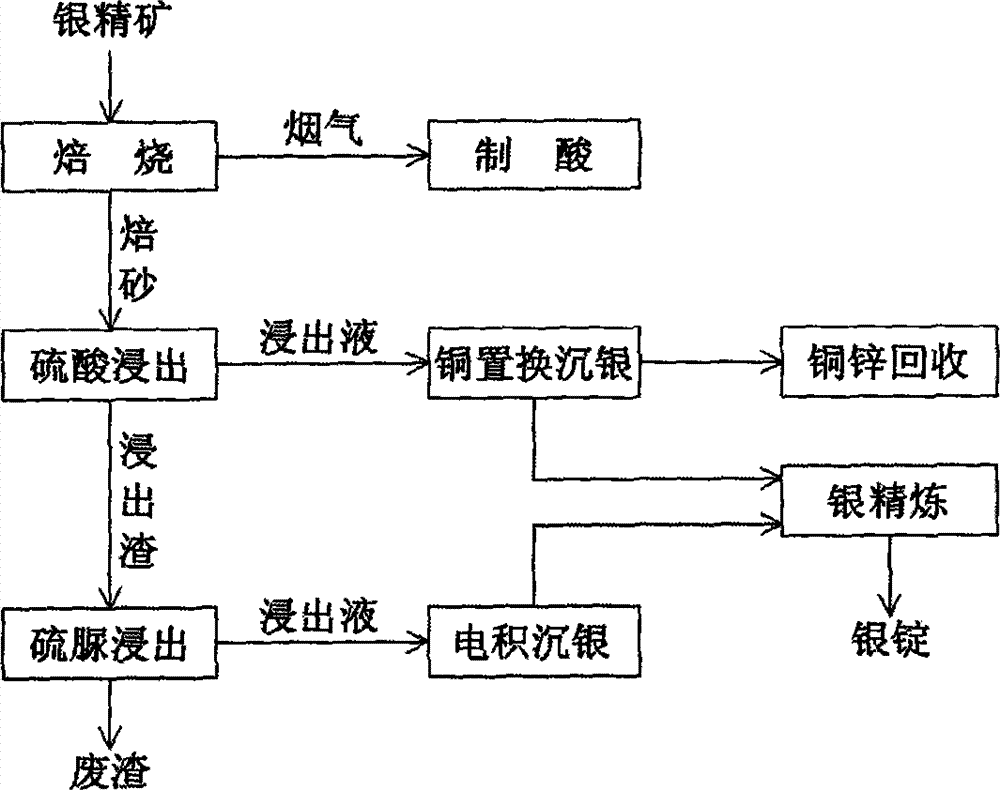

[0021] Example 1: Such as figure 1 with figure 2 As shown, a comprehensive recovery system process of hydro-zinc smelting, which includes hydro-zinc smelting process, flotation recovery process, extraction recovery process and silver concentrate extraction valuable metal process;

[0022] The wet zinc smelting process includes a leaching step and an electrolytic zinc step. The leaching step is to first carry out a neutral leaching of the zinc calcine, and then carry out a high temperature and high acid leaching. The high temperature and high acid leaching produces high leaching slag. Electrolyte the leaching solution to obtain metallic zinc and generate electrolytic waste;

[0023] The flotation recovery process is to perform flotation after slurrying the high leaching residue, and the flotation process produces silver concentrate and ore processing wastewater;

[0024] The extraction and recovery process includes an extraction process and a back-extraction process. The extraction ...

Embodiment 2

[0031] Example 2: Others are the same as Example 1, except that the silver concentrate extraction process for valuable metals is in the roasting step (2): oxidative roasting at 680°C for 3.8 hours; in the sulfuric acid leaching step ( 3) Medium: solid-liquid ratio 1:5, starting acid 120g / L, final acid 60g / L, reaction temperature 60°C, reaction time 4 hours.

Embodiment 3

[0032] Example 3: Others are the same as Example 1, except that the silver concentrate extraction process for valuable metals is in the roasting step (2): oxidizing and roasting at 760°C for 3 hours; in the sulfuric acid leaching step (3) Medium: solid-liquid ratio 1:6, starting acid 150g / L, final acid 70g / L, reaction temperature 70°C, reaction time 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com