Manufacturing method of mulberry twig briquetting fuel

A manufacturing method and a technology for forming fuel, which are applied in the field of sericulture waste utilization and environmental protection, can solve problems such as environmental pollution in silkworm production areas, increase the income of silkworm farmers, achieve significant social and environmental benefits, and eliminate environmental and atmospheric The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

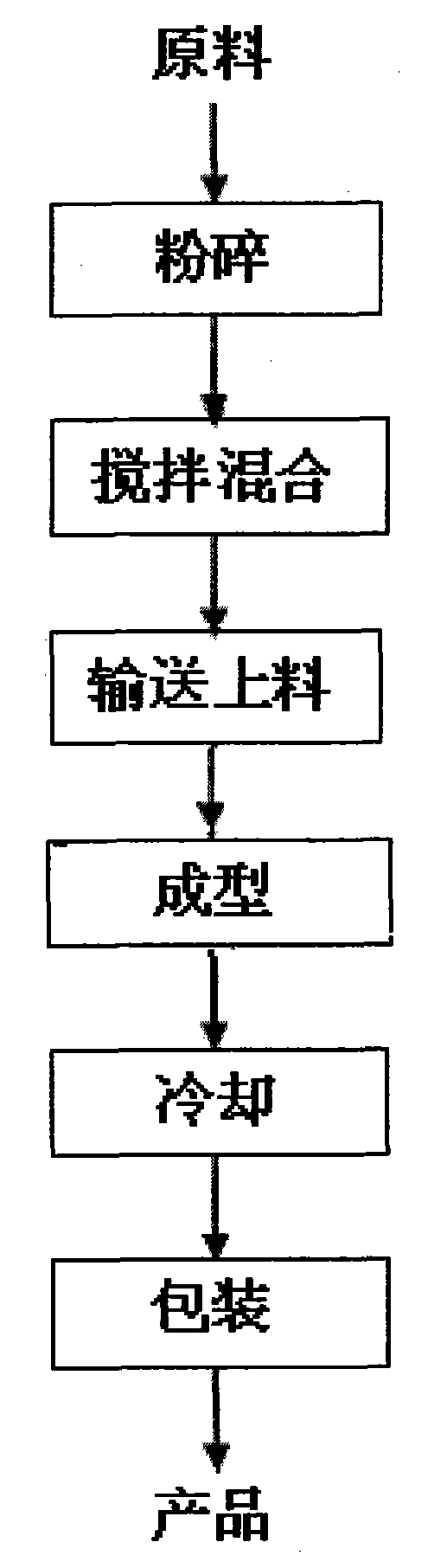

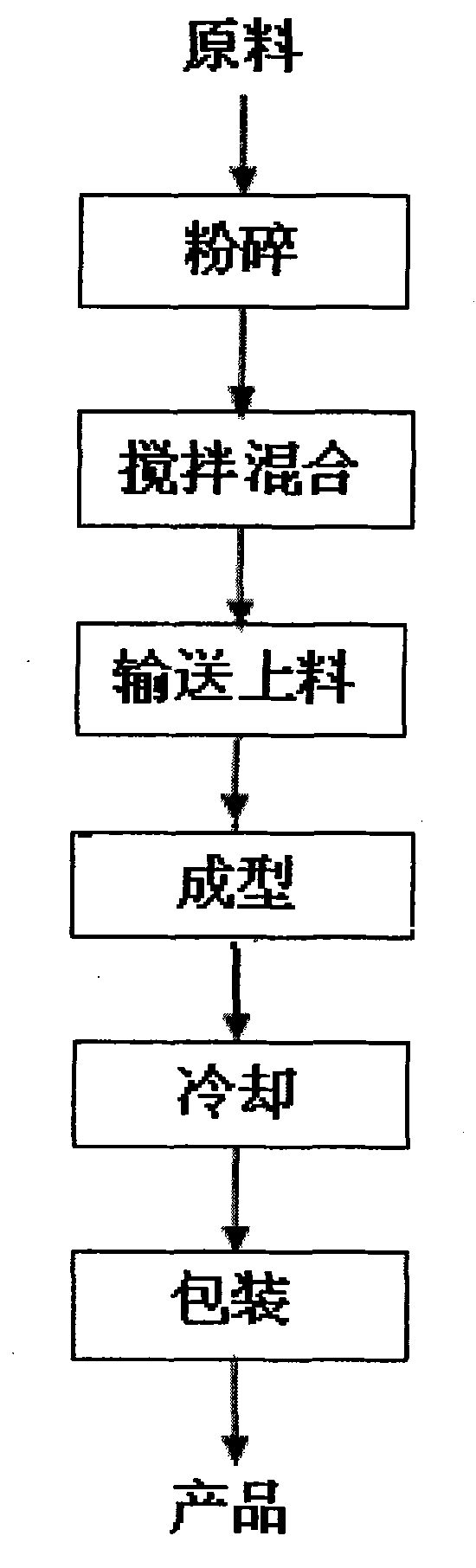

[0019] Such as figure 1 Shown, the manufacture method of mulberry twig briquette fuel is that the raw material mulberry twig is poured into the pulverizer to pulverize, and then the weight of 95 parts of mulberry branch powder, 2 parts of combustion aid coal combustion fly ash, 2 parts of kaolin and 1 part of lime powder The parts are weighed, put into the mixer to stir and mix evenly, and then sent to the pressure roller ring model briquette forming machine through the conveyor, the control pressure is 100Mpa, the temperature is 230°C, and the intermittent extrusion is made into a prism, and the mold is demoulded. After natural cooling, the final packaging is to obtain the mulberry branch shaped fuel product. The technical indicators of this product are: the density is 1.1g / cubic centimeter, the calorific value is 4650kcal / kg, the ash content is 1.38%, and the water content is 12%.

Embodiment 2

[0021] Such as figure 1 Shown, the manufacture method of mulberry twig briquette fuel is that raw material mulberry twig is poured into pulverizer and pulverized, and then the weight of 97 parts of pulverized mulberry branch powder, 1 part of combustion aid pulverized coal, 1 part of kaolin and 1 part of lime powder The parts are weighed, put into the mixer, stirred and mixed evenly, and then sent to the pressure roller ring model briquetting machine through the conveyor to control the pressure at 200Mpa and the temperature at 150°C for continuous extrusion into a circular shape with a hole in the middle The cylinder is cooled naturally after being demoulded, and finally packaged to obtain the mulberry branch shaped fuel product. The technical indicators of this product are: the density is 1.2g / cubic centimeter, the calorific value is 4960kcal / kg, the ash content is 1.45%, and the water content is 11%.

Embodiment 3

[0023] Such as figure 1 Shown, the manufacture method of mulberry twig briquette fuel is that the raw material mulberry twig is poured into the pulverizer to pulverize, and then the weight of 95 parts of mulberry branch powder, 2 parts of combustion aid coal combustion fly ash, 2 parts of kaolin and 1 part of lime powder The parts are weighed, put into the mixer to stir and mix evenly, and then sent to the hydraulically driven piston-type molding machine through the conveyor, the control pressure is 100Mpa, and the temperature is 210°C for intermittent extrusion into prisms, and natural cooling after demoulding , and finally packaged to obtain the mulberry branch shaped fuel product. The technical indicators of this product are: the density is 1.0g / cubic centimeter, the calorific value is 4713kcal / kg, the ash content is 1.28%, and the water content is 11.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com