Method for separating and recycling aluminum foil and positive active substances in retired lithium ion power battery

A cathode active material and power battery technology, which is applied in the field of resource recovery of retired lithium-ion power batteries, can solve the problems of non-inert atmosphere and mixed-type lithium-ion power battery research, high vacuum degree requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

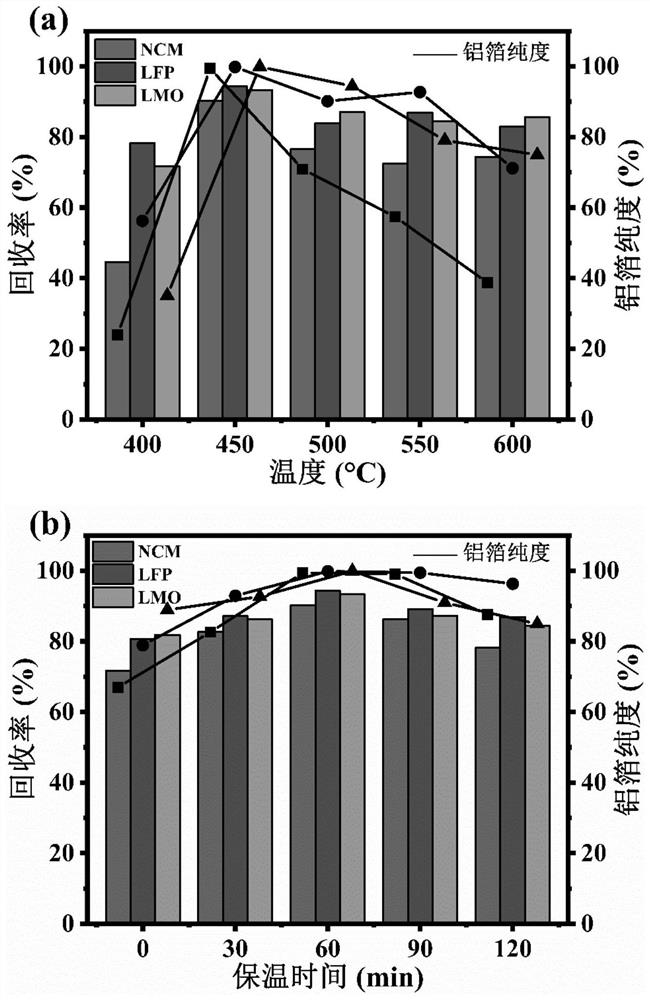

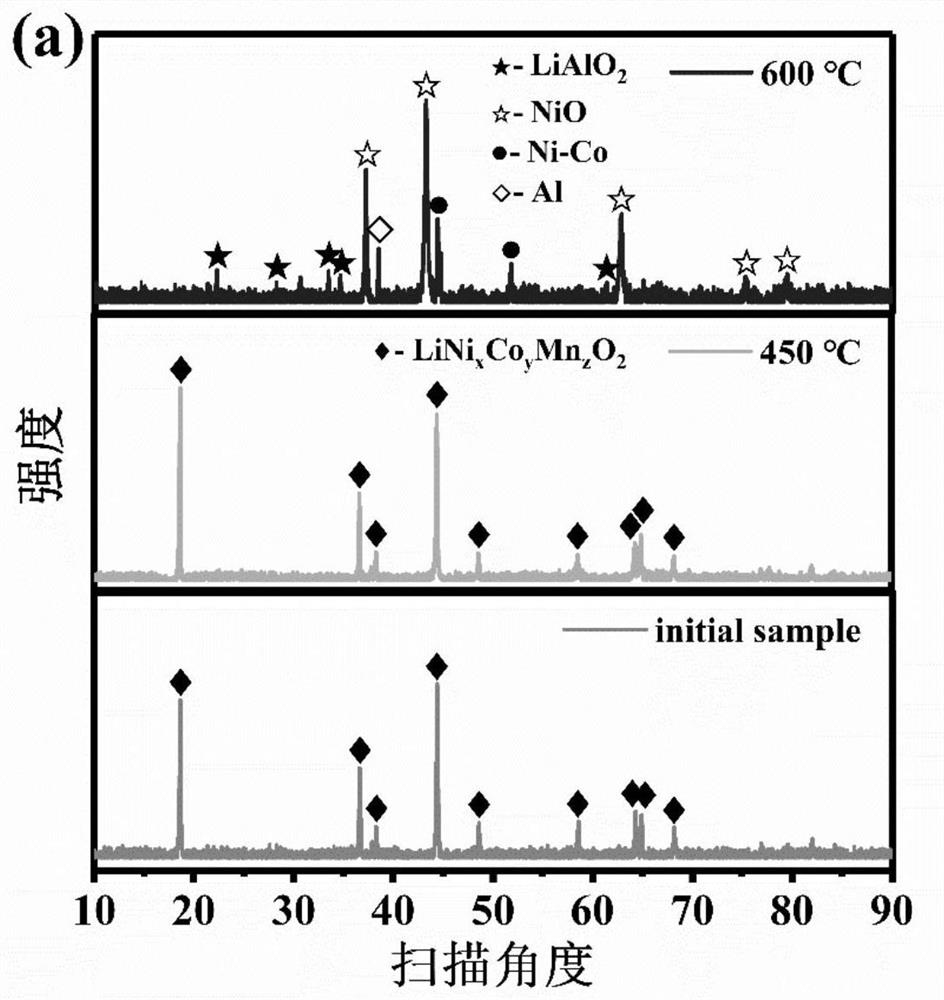

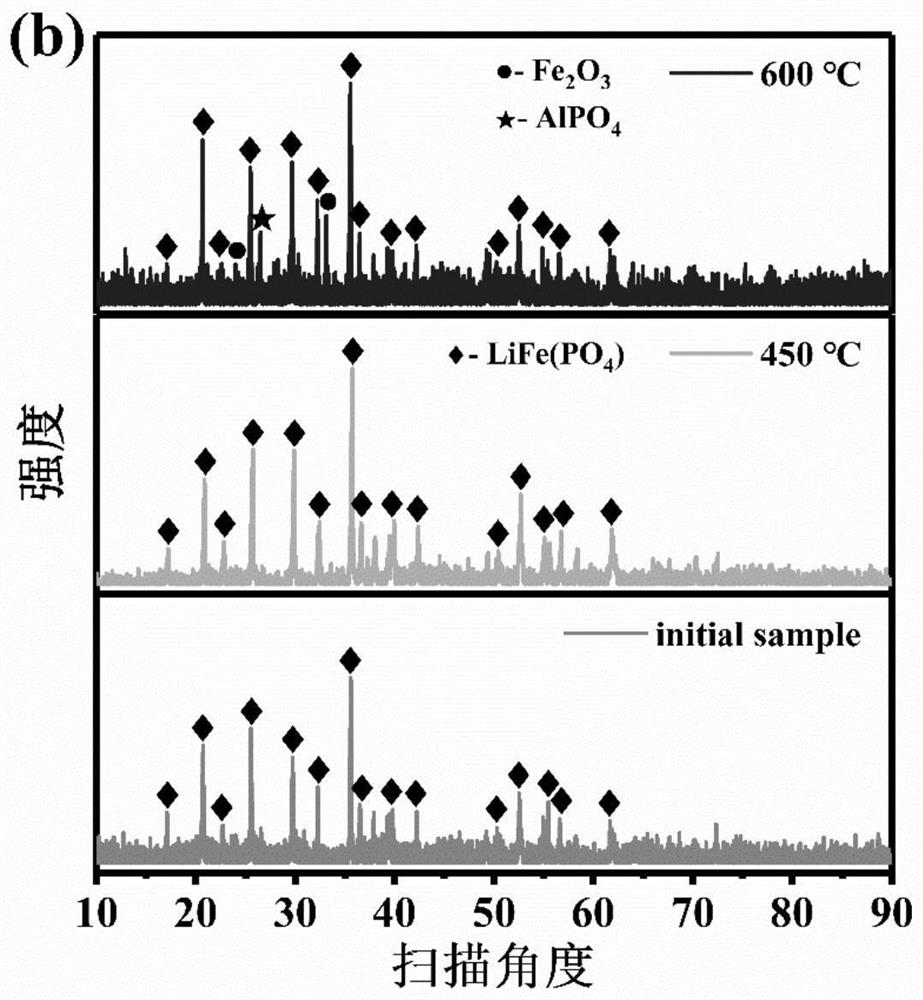

[0039] Example 1: A method for separating and recycling aluminum foil and positive electrode active material in a hybrid decommissioned lithium-ion power battery

[0040]Place the decommissioned lithium-ion power batteries of nickel-cobalt lithium manganese oxide, lithium iron phosphate, and lithium manganese oxide in a sodium chloride solution with a concentration of 50g / L for full discharge for 48 hours, then take out the battery and wash it with deionized water. Naturally air dry for more than 24 hours. After using the digital display voltmeter to confirm that the voltage is zero, fix the battery on the console and disassemble it manually step by step, collect the positive electrode pieces for backup, and store the rest in bags. Weigh 0.5g each of nickel-cobalt lithium manganese oxide, lithium iron phosphate and lithium manganese oxide positive electrode into a quartz boat, put the quartz boat into the quartz glass tube of the tube furnace, tighten and close both sides with...

Embodiment 2

[0043] On the basis of Example 1, the mass ratio of nickel-cobalt lithium manganate, lithium iron phosphate and lithium manganate was adjusted, and 1.0 g of nickel-cobalt lithium manganate was weighed, and 0.5 g of lithium iron phosphate and lithium manganate were placed in In the quartz boat, pyrolysis was carried out under the optimal pyrolysis conditions (pyrolysis temperature 450°C, holding time 60min, heating rate 10°C / min), and the rest of the steps remained unchanged. According to calculations, the recovery efficiencies of nickel-cobalt lithium manganate, lithium iron phosphate and lithium manganate cathode active materials are 90.75%, 94.29% and 90.08% respectively, and the purity of aluminum foils are 98.76%, 99.53% and 98.68% respectively.

Embodiment 3

[0045] On the basis of Example 1, the mass ratio of nickel-cobalt lithium manganate, lithium iron phosphate and lithium manganate was adjusted, and 1.0 g of lithium iron phosphate was weighed, and 0.5 g each of nickel-cobalt lithium manganate and lithium manganate were placed in In the quartz boat, pyrolysis was carried out under the optimal pyrolysis conditions, and the rest of the steps remained unchanged. According to calculations, the recovery efficiencies of nickel-cobalt lithium manganate, lithium iron phosphate and lithium manganate cathode active materials are 88.90%, 92.73% and 91.14% respectively, and the purity of aluminum foils are 98.30%, 98.04% and 99.45% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com