A kind of recycling method of lithium iron phosphate power battery

A technology of lithium iron phosphate battery and power battery, which is applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of cumbersome process, difficult recycling, high energy consumption, etc., to simplify the process, realize comprehensive utilization, The effect of amplifying recycling benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

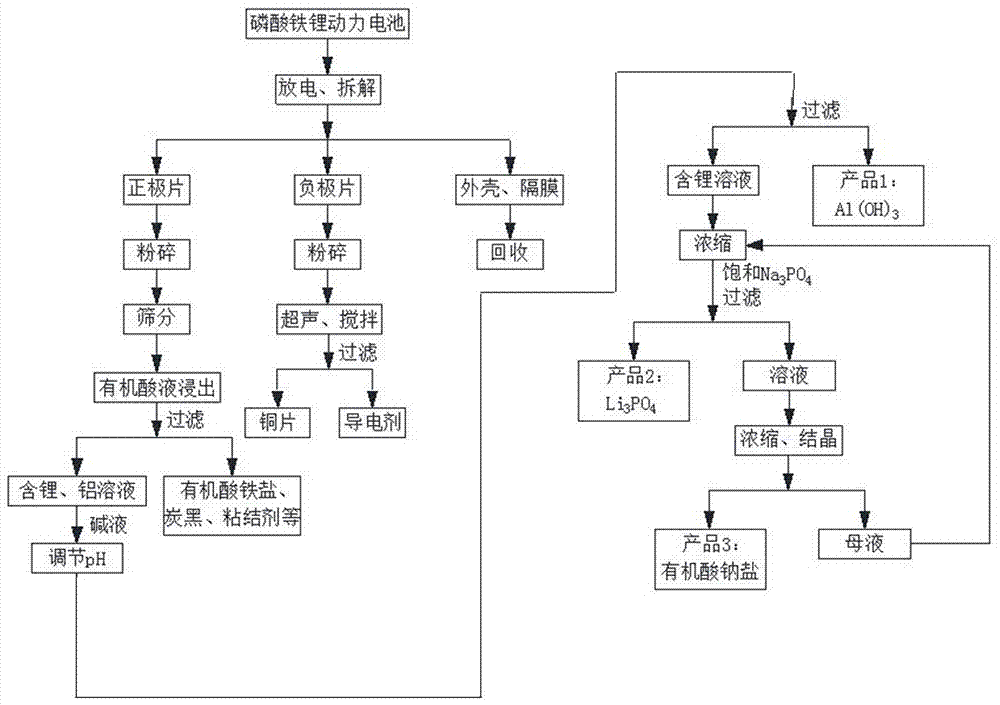

[0039] A method for recycling a lithium iron phosphate power battery, the specific steps are:

[0040] 1) Completely discharge and disassemble the waste lithium iron phosphate power battery to obtain the positive and negative electrodes, diaphragm and casing, and directly recycle the diaphragm and casing;

[0041] 2) After the negative electrode piece is crushed through an 8-mesh screen, it is immersed in water, placed in an ultrasonic machine for 60 minutes, and supplemented by stirring, and the copper piece is recovered by filtration;

[0042] 3) Crush the positive electrode, pass through an 8-mesh sieve, take 10.1053g of the material under the sieve, and use a mixed acid solution of acetic acid and oxalic acid for leaching reaction. The concentration of acetic acid is 0.5mol / L, and the concentration of oxalic acid is 1mol / L. The time is 12 hours, the reaction temperature is 50°C, the reaction solid-liquid ratio is 100 g / L, and the stirring speed is 250r / min;

[0043] 4) Fi...

Embodiment 2

[0047] A method for recycling a lithium iron phosphate power battery, the specific steps are:

[0048] 1) Discharge and disassemble the lithium iron phosphate power battery to obtain the positive and negative electrodes, diaphragm and casing, and directly recycle the diaphragm and casing;

[0049] 2) After the negative electrode sheet is crushed through an 8-mesh screen, it is immersed in water, placed in an ultrasonic machine for 1.5 hours, and the copper sheet is recovered by filtration;

[0050] 3) Crush the positive electrode, pass through an 8-mesh sieve, take 10.0399g of the material under the sieve, and use a mixed acid solution of formic acid and oxalic acid for leaching reaction. The concentration of formic acid is 1mol / L, and the concentration of oxalic acid is 2mol / L. The reaction time 9 hours, the reaction temperature is 45°C, the reaction solid-to-liquid ratio is 150g / L, and the stirring speed is 250r / min;

[0051] 4) Filter the filtrate and filter residue after ...

Embodiment 3

[0055] A method for recycling a lithium iron phosphate power battery, the specific steps are:

[0056] 1) Discharge and disassemble the lithium iron phosphate power battery to obtain the positive and negative electrodes, diaphragm and casing; the diaphragm and casing are directly recycled;

[0057] 2) After the negative electrode piece is crushed through an 8-mesh sieve, it is immersed in water, placed in an ultrasonic machine for 2 hours, and the copper piece is recovered by filtration;

[0058] 3) Crush the positive electrode, pass through an 8-mesh sieve, take 9.9358g of the material under the sieve, and use a mixed acid solution of acetic acid, oxalic acid and citric acid for leaching reaction, the concentration of acetic acid is 2mol / L, and the concentration of oxalic acid is 3mol / L , the concentration of citric acid is 1mol / L, the reaction time is 5 hours, the reaction temperature is 45°C, the reaction solid-liquid ratio is 180g / L, and the stirring speed is 250r / min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com